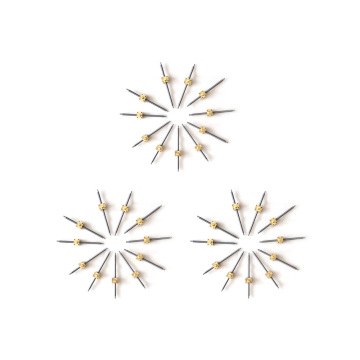

Diameter 10mm pitch 3mm Tr10x3 lead screw

- Transportation:

- Land, Air, Express, Ocean

- Port:

- shanghai

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,CPT,FCA,Express Delivery,DDU,DDP |

| Transportation: | Land,Air,Express,Ocean |

| Port: | shanghai |

Product Description

Product Description

The quality trapezoidal screw manufacturing process consists of the following seven steps:

- Material preparation: Select the appropriate material, usually high-strength steel or stainless steel.

- Processing: According to the design requirements, the material is cut, turning, milling and other processing technology to produce the shape and size of the trapezoid lead screw.

- Heat treatment: Heat treatment of the ladder screw, usually quenching or tempering, to improve its strength and hardness.

- Finishing: Precision machining of the trapezoid screw, including grinding, grinding, polishing and other processes to improve its surface quality and accuracy.

- Surface treatment: Surface treatment of trapezoidal screw, such as chrome plating, spraying, etc., to improve its corrosion resistance and beauty.

- Inspection: The trapezoidal screw is inspected, including appearance inspection, size inspection, hardness test, etc., to ensure that it meets the design requirements and standard requirements.

- Packaging: the trapezoidal screw is packaged for transportation and storage.

Related Keywords

Related Keywords