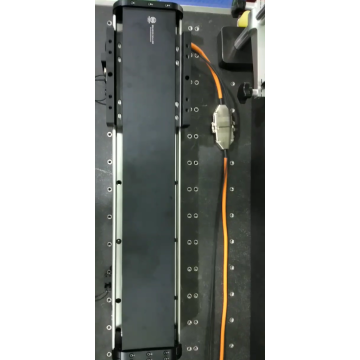

Linear motor for flexible OLED fitting equipment

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 sets/month |

| Supply Ability: | 10000sets/month |

| Payment Type: | T/T,Paypal,D/A,D/P |

| Incoterm: | FOB,CIF,EXW,FCA,CPT,DDU |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai |

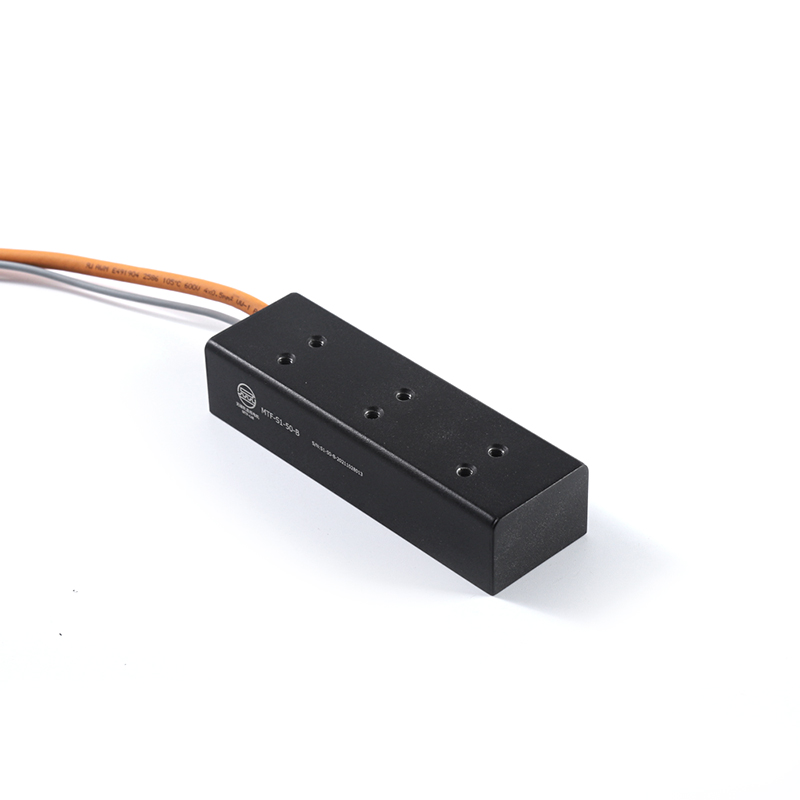

Seidal has a total of 20 products in the S1, S2 and S3 series. The maximum speed can reach 18m/s, the maximum acceleration can reach 15G, the thrust range is from 63N to 1500N, and the vertical suction is only 1/3 of the conventional linear motor, which greatly extends the guide life.MTF Linear Motors can effectively overcome the disadvantages of large magnet consumption and low magnet utilization of the conventional linear motor. The stator of the magnetic-track-free linear motor does not use magnets, but the powder magnetic conductive materials.The material has high permeability, high saturation flux and is easy to be manufactured by metallurgical die casting. MTF Linear Motors put the magnet inside the actuator, and when the actuator moves, the corresponding magnet moves. That is, the motor will have the excitation of the magnet with movement, the magnet movement to which part, which part of the electromagnetic force. Thus, as the rotary permanent magnet synchronous motor, the magnet utilization rate reaches 100%, no extra magnet is exposed. As a result, the cost of linear motors is greatly reduced and safety is improved.Compared with high-cost magnetic rail linear motors on the market, our linear motors can save a large amount of rare earth materials and save at least 70% of the cost, especially for long-track linear motors. Our Linear Motor Module is worth buying.In the future,our Linear Motor Application will become more and more widespread.

How Non Magnetic Track linear motor works?

About our MTF Linear Motors working principle, the most basic electromagnetic theory is still unchanged, but it adopts the latest magnetic field modulation theory, self-modulated ferroalloy stator. We transfer the magnet supposed to be laid on the stator to the mover, so that the coil and magnet are integrated on the mover.The synonym-shaped design on the stator provides a magnetic circuit that essentially interacts with two magnetic fields to generate thrust

When the mover moves, the corresponding magnet also moves with it. That is, the activist will have an excitation magnet with a movement, magnet movement to which part, which part produces electromagnetic force. Thus, like the rotating permanent magnet synchronous motor, the magnet utilization rate reaches 100%, and no extra magnets are exposed. The design of this structure overcomes two shortcomings of conventional linear motors.Namely, the large amount of magnets and the low utilization rate. This greatly reduces the cost of linear motors and improves safety.

Linear motor actuator application:

Ic Package,Testing Of Semiconductor Equipments

Ic Patching,Photovoltaic Panel Manufacturing

Laser Cutting Equipments,

Medical Apparatus And Instruments,Machine Tools,Optical Equipments,Display Panel Manufacturing.

Features and Performance

Product categories of advanced Linear Motor Module,as the professional linear motor and encoder manufacturer from China,we provide competitive linear motor modules.Self-developed new technology magnetic track free linear motor.Manufacturing and wholesale high quality Single Axis Robots.ALM has the perfect after-sales service and technical support. Look forward to your cooperation!

Related Keywords