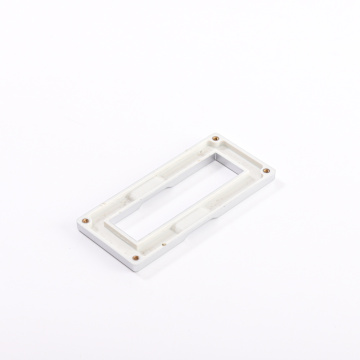

custom injection moulding plastic

- Min. Order:

- 1000 Piece/Pieces

- Min. Order:

- 1000 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 1000000 |

| Supply Ability: | 10000000 |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

Product Description

Product Description

Company Profile:

Suzhou Dongye Precision Molding Co., Ltd. was established in 2012, specializing in the production of high-precision plastic molds and plastic products

From molding to mass production of precision electrical parts and medical, plastic food parts, communications equipment, toys, crafts.

Covering an area of 1000 square meters, the company has a one-stop precision mold workshop and an injection molding center for 100,000 grade purifiers.

Includes product design assistance, mold design and manufacturing, and turnkey services for production and assembly.

OEM plastic injection mold parts, precision injection molding for Marine industry

Plastic parts, injection parts, plastic injection parts, injection molding, injection parts, Plastic Parts, Pvc Injection

The application of plastic molds

Household utility ware

Auto parts and components

Computer and electronic products

Electronic components and components

Sample for sale

Medical and dental products

Model shops, toys, hobbies

New product design and development

Furniture Design

Civil engineering

The construction of

Marine industry

Garden products

Military industry

Description:

Short cycle time:

We will design the best cooling system for uniform cooling of plastic molds including: cushion, spring and beryllium copper cooling system. The cooling system mainly determines the cost of the parts.

Quality control

1. Quality control of incoming materials: inspect all steel and outsourced standard parts to ensure that they meet the requirements of customized plastic molds;

2. In terms of process quality control: all processing and assembly processes are under control. We have a QC team to check and supervise whether tolerances and machined surfaces meet the requirements;

3. Final quality control: After the plastic mold is completed, we will thoroughly check the plastic sample and the main size of the mold to ensure that every step is not ignored and the quality of the plastic mold is ok.

After-sales service:

Spare parts are provided, such as: spring, ejection needle...

Mold maintenance as much as possible

Some insert or plate costs are paid

Can provide mold and plastic parts design

Prototype: CNC, SLC SLS available

Available for injection molding

Procedure

a. Provide competitive prices according to customer's detailed requirements

B. Sign the agreement

c. The customer telegraphic deposit to us to start the mold design

d. Send the mold drawing to the customer for confirmation

e. Mold design confirmation, start to make the mold

f. Conduct mold trials during mold processing (reach agreement with customer)

g. Send the sample to the customer for inspection. Or customers come to our factory to personally inspect the mold

h. The customer will send us the wire transfer after the mold is confirmed

i. Mold out after balance

We provide:

Multi cavity die

Mould for home

Hot runner mold

Rapid prototyping

Molding of plastics

The assembly

Secondary operation

Company Advantages:

1-2 years OEM and ODM experience in plastic mold and injection molding service in electronics, medical, automotive, etc

Spare parts, food plastic accessories, communication equipment, toys and crafts: one-stop mold room, injection molding center.

2- Advanced equipment and professional technology: CNC, CMM, precision mold room and 100,000 injection molding machines

Class cleans injection room.

3- Advanced R & D services and best engineers :DFM, mold flow analysis and project design assistance.

4- High quality IML (In Mold Labeling) technology, we can produce IML mold labeling.

Quality and price: quality oriented, analyze cost drivers and work with customers to reduce costs.

6- Range of services for design, prototyping, painting, printing and simple assembly.

Suzhou Dongye Precision Molding Co., Ltd. was established in 2012, specializing in the production of high-precision plastic molds and plastic products

From molding to mass production of precision electrical parts and medical, plastic food parts, communications equipment, toys, crafts.

Covering an area of 1000 square meters, the company has a one-stop precision mold workshop and an injection molding center for 100,000 grade purifiers.

Includes product design assistance, mold design and manufacturing, and turnkey services for production and assembly.

OEM plastic injection mold parts, precision injection molding for Marine industry

Plastic parts, injection parts, plastic injection parts, injection molding, injection parts, Plastic Parts, Pvc Injection

The application of plastic molds

Household utility ware

Auto parts and components

Computer and electronic products

Electronic components and components

Sample for sale

Medical and dental products

Model shops, toys, hobbies

New product design and development

Furniture Design

Civil engineering

The construction of

Marine industry

Garden products

Military industry

Description:

Short cycle time:

We will design the best cooling system for uniform cooling of plastic molds including: cushion, spring and beryllium copper cooling system. The cooling system mainly determines the cost of the parts.

Quality control

1. Quality control of incoming materials: inspect all steel and outsourced standard parts to ensure that they meet the requirements of customized plastic molds;

2. In terms of process quality control: all processing and assembly processes are under control. We have a QC team to check and supervise whether tolerances and machined surfaces meet the requirements;

3. Final quality control: After the plastic mold is completed, we will thoroughly check the plastic sample and the main size of the mold to ensure that every step is not ignored and the quality of the plastic mold is ok.

After-sales service:

Spare parts are provided, such as: spring, ejection needle...

Mold maintenance as much as possible

Some insert or plate costs are paid

Can provide mold and plastic parts design

Prototype: CNC, SLC SLS available

Available for injection molding

Procedure

a. Provide competitive prices according to customer's detailed requirements

B. Sign the agreement

c. The customer telegraphic deposit to us to start the mold design

d. Send the mold drawing to the customer for confirmation

e. Mold design confirmation, start to make the mold

f. Conduct mold trials during mold processing (reach agreement with customer)

g. Send the sample to the customer for inspection. Or customers come to our factory to personally inspect the mold

h. The customer will send us the wire transfer after the mold is confirmed

i. Mold out after balance

We provide:

Multi cavity die

Mould for home

Hot runner mold

Rapid prototyping

Molding of plastics

The assembly

Secondary operation

Company Advantages:

1-2 years OEM and ODM experience in plastic mold and injection molding service in electronics, medical, automotive, etc

Spare parts, food plastic accessories, communication equipment, toys and crafts: one-stop mold room, injection molding center.

2- Advanced equipment and professional technology: CNC, CMM, precision mold room and 100,000 injection molding machines

Class cleans injection room.

3- Advanced R & D services and best engineers :DFM, mold flow analysis and project design assistance.

4- High quality IML (In Mold Labeling) technology, we can produce IML mold labeling.

Quality and price: quality oriented, analyze cost drivers and work with customers to reduce costs.

6- Range of services for design, prototyping, painting, printing and simple assembly.

Related Keywords

Related Keywords