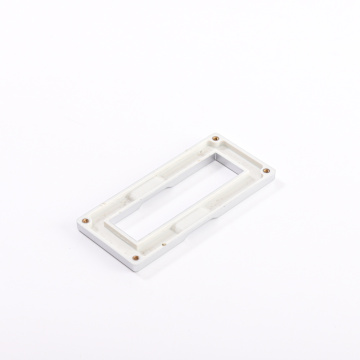

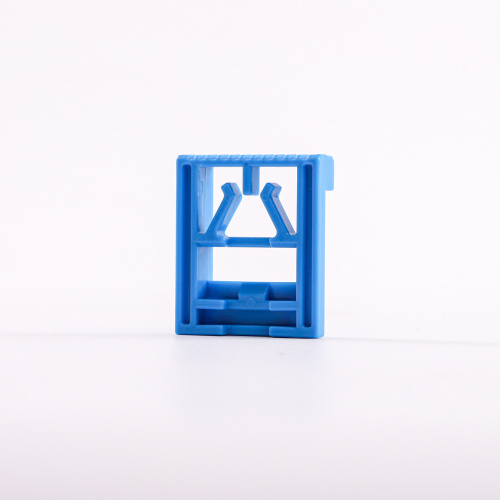

quality plastic injection components

- Min. Order:

- 1000 Piece/Pieces

- Min. Order:

- 1000 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 10000000 |

| Supply Ability: | 1000000 |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

Product Description

Product Description

Quality plastic injection components refer to products that are made through the process of plastic injection molding, which involves injecting molten plastic material into a mold cavity to produce a specific shape or design. These components are used in various industries such as automotive, medical, electronics, and consumer goods.

To ensure high-quality plastic injection components, manufacturers need to follow strict quality control measures throughout the production process. This includes using high-quality raw materials, maintaining the correct temperature and pressure during molding, and conducting rigorous testing and inspection of finished products. Pvc Injection

Some of the key factors that contribute to the quality of plastic injection components include:

1. Material selection: Using the right type of plastic material is crucial in producing high-quality components that meet the required specifications.

2. Molding process: The molding process should be carefully controlled to ensure consistent and accurate production of components.

3. Tooling design: The design of the mold tooling should be optimized to ensure the production of high-quality components with minimal defects.

4. Quality control: Regular inspection and testing of components are necessary to ensure they meet the required standards and specifications.

Overall, producing quality plastic injection components requires a combination of expertise, experience, and attention to detail. Manufacturers who prioritize quality control measures and invest in high-quality materials and equipment are more likely to produce components that meet customer expectations and industry standards.

Suzhou tolo precision molding co., LTD., mainly for the project structure modeling expert hand, rapid prototyping, small batch production, industrial product design and other supporting services, auto parts, medical equipment, household appliances, bluetooth headsets and other digital products shell precision production has reached the leading level, and constantly develop and research new technologies, guarantee the development of customer and market demand, For customers to shorten the proofing cycle and reduce the development cost and continuous efforts. First, the main business scope includes: CNC hand mold, industrial design. Two, the use of materials :ABS, POM, PC, PA6, PA66, PMMA, aluminum, iron, steel, bakelite, EVA, etc. Three, to undertake products: mobile phone, digital camera, MP4 high-end digital HANDHELD, handheld appliances, electronic chassis HANDHELD, handheld medical equipment. Fourth, vacuum mode: small batch replication materials include :ABS, PU, PVC, silica gel, transparent ABS, etc.

1. Besides molds, do you also produce products? Yes, we can do your project for your factory in Suzhou. But we can only make it by making a new mold... Then, from the new mold above, make the parts out. We do production work for our customers in Suzhou. In other words, we don't have any existing molds. In short, we make custom moulds and products, but we also provide reverse engineering services for our customers.OEM plastic injection mold parts, precision injection molding for Marine industry

Description:

Short cycle time:

We will design the best cooling system for uniform cooling of plastic molds including: cushion, spring and beryllium copper cooling system. The cooling system mainly determines the cost of the parts.

Quality control

1. Quality control of incoming materials: inspect all steel and purchased standard parts to ensure that they meet the requirements of customized plastic molds;

2. In terms of process quality control: all processing and assembly processes are under control. We have a QC team to check and supervise whether tolerances and machined surfaces meet the requirements;

3. Final quality control: After the plastic mold is completed, we will thoroughly check the plastic sample and the main size of the mold to ensure that every step is not ignored and the quality of the plastic mold is ok.

After-sales service:

Spare parts are provided, such as: spring, ejection needle...

Mold maintenance as much as possible

Some insert or plate costs are paid

Can provide mold and plastic parts design

Prototype: NC, SLC, SLS available

Injection molding

To ensure high-quality plastic injection components, manufacturers need to follow strict quality control measures throughout the production process. This includes using high-quality raw materials, maintaining the correct temperature and pressure during molding, and conducting rigorous testing and inspection of finished products. Pvc Injection

Some of the key factors that contribute to the quality of plastic injection components include:

1. Material selection: Using the right type of plastic material is crucial in producing high-quality components that meet the required specifications.

2. Molding process: The molding process should be carefully controlled to ensure consistent and accurate production of components.

3. Tooling design: The design of the mold tooling should be optimized to ensure the production of high-quality components with minimal defects.

4. Quality control: Regular inspection and testing of components are necessary to ensure they meet the required standards and specifications.

Overall, producing quality plastic injection components requires a combination of expertise, experience, and attention to detail. Manufacturers who prioritize quality control measures and invest in high-quality materials and equipment are more likely to produce components that meet customer expectations and industry standards.

Suzhou tolo precision molding co., LTD., mainly for the project structure modeling expert hand, rapid prototyping, small batch production, industrial product design and other supporting services, auto parts, medical equipment, household appliances, bluetooth headsets and other digital products shell precision production has reached the leading level, and constantly develop and research new technologies, guarantee the development of customer and market demand, For customers to shorten the proofing cycle and reduce the development cost and continuous efforts. First, the main business scope includes: CNC hand mold, industrial design. Two, the use of materials :ABS, POM, PC, PA6, PA66, PMMA, aluminum, iron, steel, bakelite, EVA, etc. Three, to undertake products: mobile phone, digital camera, MP4 high-end digital HANDHELD, handheld appliances, electronic chassis HANDHELD, handheld medical equipment. Fourth, vacuum mode: small batch replication materials include :ABS, PU, PVC, silica gel, transparent ABS, etc.

1. Besides molds, do you also produce products? Yes, we can do your project for your factory in Suzhou. But we can only make it by making a new mold... Then, from the new mold above, make the parts out. We do production work for our customers in Suzhou. In other words, we don't have any existing molds. In short, we make custom moulds and products, but we also provide reverse engineering services for our customers.OEM plastic injection mold parts, precision injection molding for Marine industry

Description:

Short cycle time:

We will design the best cooling system for uniform cooling of plastic molds including: cushion, spring and beryllium copper cooling system. The cooling system mainly determines the cost of the parts.

Quality control

1. Quality control of incoming materials: inspect all steel and purchased standard parts to ensure that they meet the requirements of customized plastic molds;

2. In terms of process quality control: all processing and assembly processes are under control. We have a QC team to check and supervise whether tolerances and machined surfaces meet the requirements;

3. Final quality control: After the plastic mold is completed, we will thoroughly check the plastic sample and the main size of the mold to ensure that every step is not ignored and the quality of the plastic mold is ok.

After-sales service:

Spare parts are provided, such as: spring, ejection needle...

Mold maintenance as much as possible

Some insert or plate costs are paid

Can provide mold and plastic parts design

Prototype: NC, SLC, SLS available

Injection molding

Related Keywords

Related Keywords