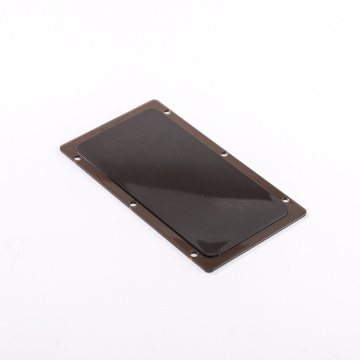

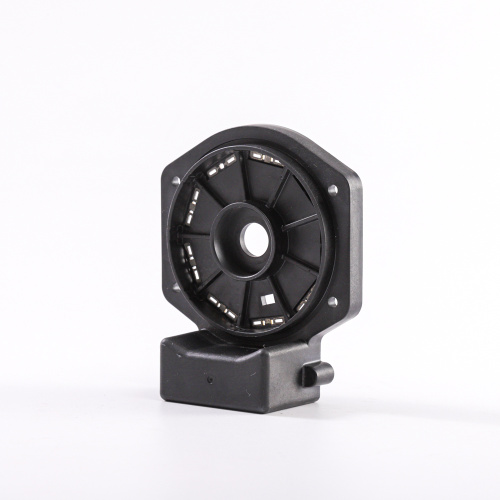

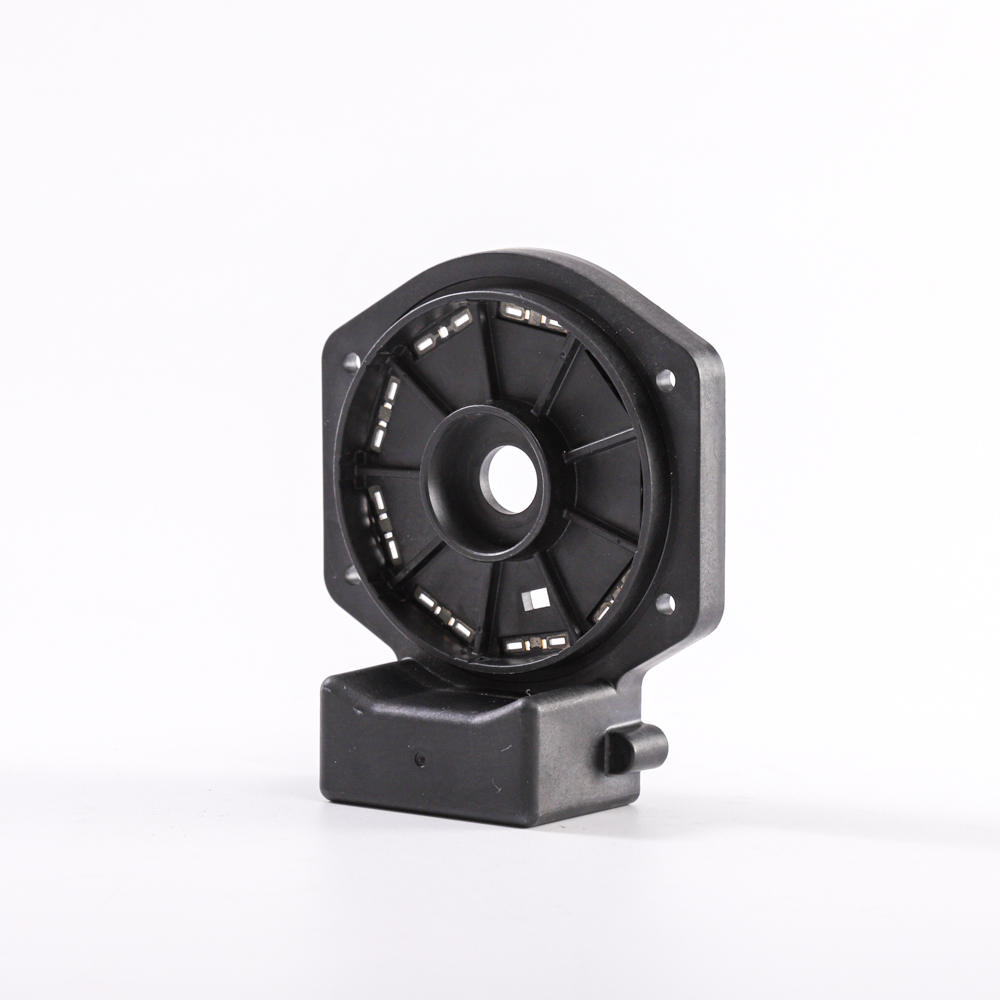

Micro injection molding/plastic parts

- Min. Order:

- 1000 Piece/Pieces

- Min. Order:

- 1000 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000 |

| Supply Ability: | 1000000 |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

Micro injection molding/plastic parts

Micro injection molding is a manufacturing process used to produce small plastic parts with high precision and accuracy. It involves injecting melted plastic material into a mold cavity under high pressure and then cooling and solidifying the material to form the desired shape.

Micro Injection MoldingMicro injection molding is suitable for producing small parts with complex geometries and tight tolerances, such as micro gears, micro connectors, microfluidic devices, and medical implants. The process can use a variety of thermoplastic materials, including engineering plastics, elastomers, and bioresorbable polymers.

The advantages of micro injection molding include:

- High precision and accuracy

- Consistent part quality

- Low material waste

- Short lead times and fast production cycles

- Cost-effective for high-volume production

Some of the challenges of micro injection molding include:

- Tooling costs can be high due to the complexity of the molds

- Choosing the right material and processing parameters can be critical for achieving the desired properties and performance of the parts

- Part design must take into account the limitations of the process, such as draft angles, wall thickness, and gate location.

Research and development ability

1. In order to meet your high quality requirements, we produce in accordance with 5s management system and iso 9001:2008 standard.

2. Apply the latest cad/cam technology in design, tooling and engineering. Design, technical team work, proficient in 2D /3D software (Pro-E, Auto CAD, Solidworks)

3. We provide :dfm, mold flow analysis and project design assistance.

Advantages of the company:

1-2 YEARS oem AND odm EXPERIENCE IN PLASTIC MOLD AND INJECTION MOLDING IN ELECTRONICS, MEDICAL, AUTOMOTIVE, ETC

Spare PARTS, FOOD plastic accessories, communication equipment, toy crafts: one-stop mold room, injection center.

2- Advanced equipment and professional technology: numerical control, three coordinate, precision mold room and 100,000 injection molding machines

Class clean injection room.

3- Advanced R&D services and best engineers :dfm, mold flow analysis and project design assistance.

4- High quality IML(in-mold labeling) technology, we can produce IML molds.

Quality and price: Quality oriented, analyze cost drivers, work with customers to reduce costs.

6- Series of services for design, prototyping, painting, printing and simple assembly.Micro Injection Molding

Micro injection is a technique used to inject small volumes of liquid into a target material. It involves using a very small needle or syringe to inject the liquid into a specific location. This technique is commonly used in the manufacturing of microelectronic devices, medical devices, and other precision components. Micro injection allows for precise control over the amount of liquid injected and the location of the injection, making it ideal for applications where accuracy and precision are critical. Micro Injection Molding

Related Keywords