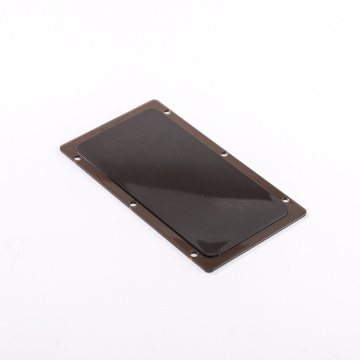

Precision micro injection molding

- Min. Order:

- 1000 Piece/Pieces

- Min. Order:

- 1000 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000000 |

| Supply Ability: | 1000000 |

| Payment Type: | T/T,L/C |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

Professional injection molding custom products for 20 years, to provide you with assured custom experience, in order to ensure product quality, the company strictly in accordance with the ISO9001:2015 quality management system management, one-stop assembly and packaging services, mass free design, affordable, quality assurance is your trusted source manufacturers. In order to ensure product quality, the company strictly in accordance with the ISO9001:2015 quality management system management. Our expertise in tight tolerance injection molding and our extensive knowledge of micromolded materials enable us to advance polymer science.

Micro-molding is one of the more difficult injection molding processes. In essence, the polymers used have "macromolecules". Working with these molecules at the tiny sizes required for micromolding can be tricky because they tend to behave differently than in larger applications. And, while all injection molding processes require strict tolerances, this is especially true in micromolding; Even the tiniest dimensional change can make parts of this size unusable.

Due to the unique and specialized nature of micromolding processes, we have to design new micromolding solutions for almost every project we undertake. Micromolding of very small parts naturally requires very small molds and tools. Because some of the mold pins, mold parts, etc., are only a few thousandths of an inch in diameter, even the metals we use in the mold become very fragile. Our molds and tools are manufactured using special micromolding sources to ensure high quality and durability.

There are many reasons for micromolding projects, including:

We utilize state-of-the-art injection micromolding equipment

Our team has many years of experience in micromolding and tight tolerance molding

We employ a helpful, knowledgeable staff that understands micromolding solutions

We provide microfluidic chip manufacturing or molding

We will work with you to find the ideal plastic material for your micromolding process application

With more than 20 years of experience in plastic injection molding, we know what is effective, what is invalid We can customize according to the need for design and engineering advice, help customers faster and more efficient and cheaper to manufacture products for the product design and manufacturing needs of customers provide the most timely solution Never stop self improvement Suzhou Dongye Precision Mould Co., Ltd. was established in Suzhou, China. Our aim is to contribute to the success of our customers. Dongye enjoys a reputation in precision metal stamping, plastic injection molding, custom inserts, custom superdie pressing and silicone rubber compression molding, etc Suzhou Dongye Precision Molding Co., LTD., located in Suzhou, China, has two production bases with a total scale of over 1000 meters. Micro Injection Molding

In summary, the company will provide a wide range of integrated operation capabilities, from design to production of moulds 100% manufactured in Suzhou.

With Suzhou's performance level, we meet the world's customers with the most valuable mold manufacturing process: customer design services; Prototype design; Mold manufacturing; Production process control; Reverse engineering; Customer tooling, assembly, etc.

We produce plastic injection moulds, die casting moulds, silicone rubber moulds, liquid silicone rubber moulds, LSR moulds, rubber moulds, press moulds and hot runner moulds (MoldMaster, MasterFlow, LKM, Incoe system, etc.).

We specialize in concave mould, cap screw mould, core pulling structure mould, high gloss polishing mould, interchangeable core mould, hot pressing mould, two component injection mould, small batch production pilot mould, etc.

Related Keywords