mini micro tact switch

- Min. Order:

- 1000 Piece/Pieces

- Min. Order:

- 1000 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000000 |

| Supply Ability: | 1000000 |

| Payment Type: | T/T,L/C |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

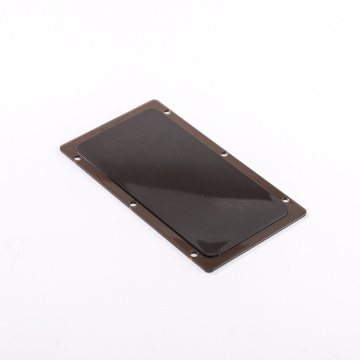

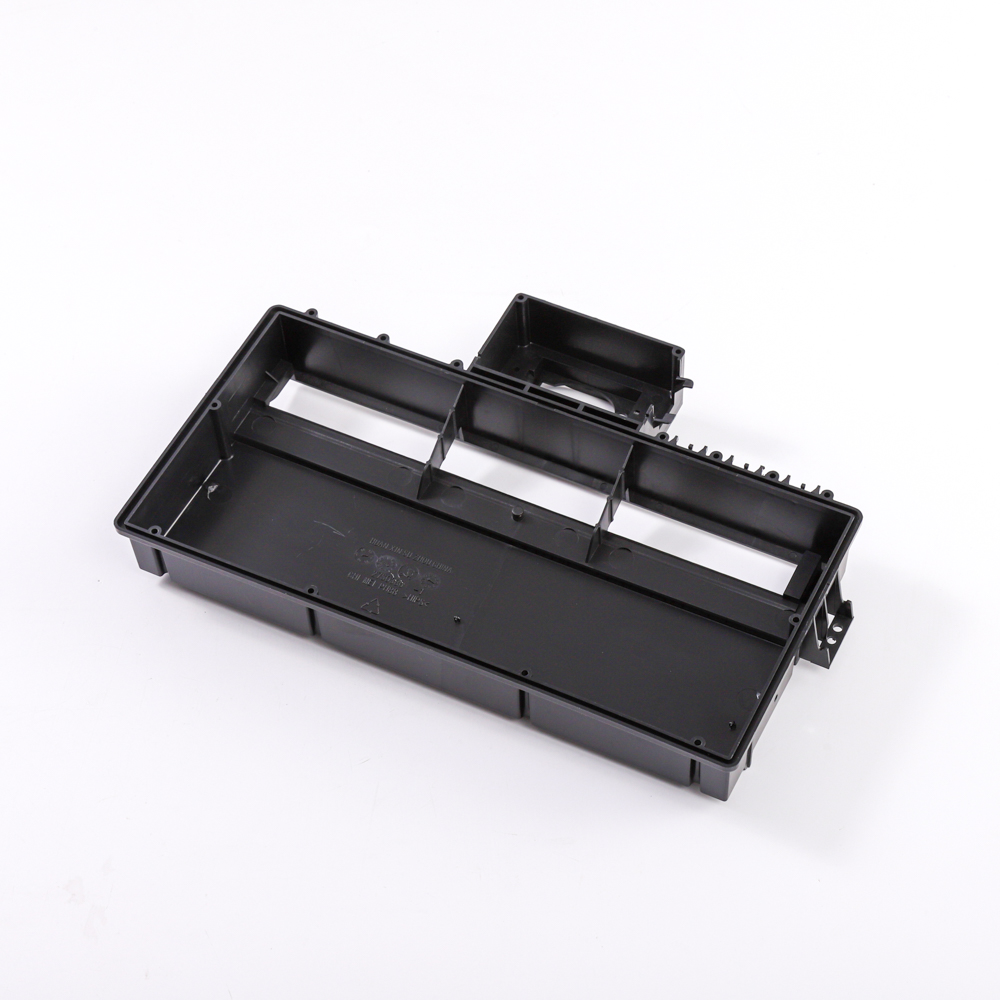

We produce injection molding products, carefully designed, comprehensive introduction, try to do everything, this is our sincerity, use a wider range, more durable. Professional injection molding custom products for 20 years, to provide you with the rest of the customization experience. In the industry for many years of production experience, according to the drawings to sample processing orders, manufacturers quality assurance, complete specifications, high-quality after-sales service, modern complete sets of production equipment and first-class staff, the annual production capacity of nearly one thousand tons. Liquid silicone vulcanization molding equipment, injection molding process, extrusion/extrusion. Our company adopts the most advanced injection molding technology, can produce 0.14mm-8mm thick plastic products, including ABS, PS, PP, PE, PVC, PC, PET and other plastic products. The main products are mobile phone shell, refrigerator inside plastic frame, projection TV back shell, plastic light box, plastic figures, plastic bags, plastic cups, car dashboard parts, seat back parts, door cover parts, toy car shell and so on. Compared with the peers, the technology mold cost is lower, the research time is shorter, the mold production time is shorter, can greatly reduce the production cost and cycle. Our company can also make molds for customers, low cost, high quality products. At the same time, we will provide services for the whole mold project development, including design, mold manufacturing, plastic parts production and after-sales service. The company also has a wide range of injection molding products, the main products are mobile phone shell, refrigerator glue rack, projection TV back shell, plastic light box, plastic words, plastic bags, plastic cups, car dashboard accessories, seat back accessories, car door accessories, toy car shell and so on. Micro Injection Molding

Related Keywords