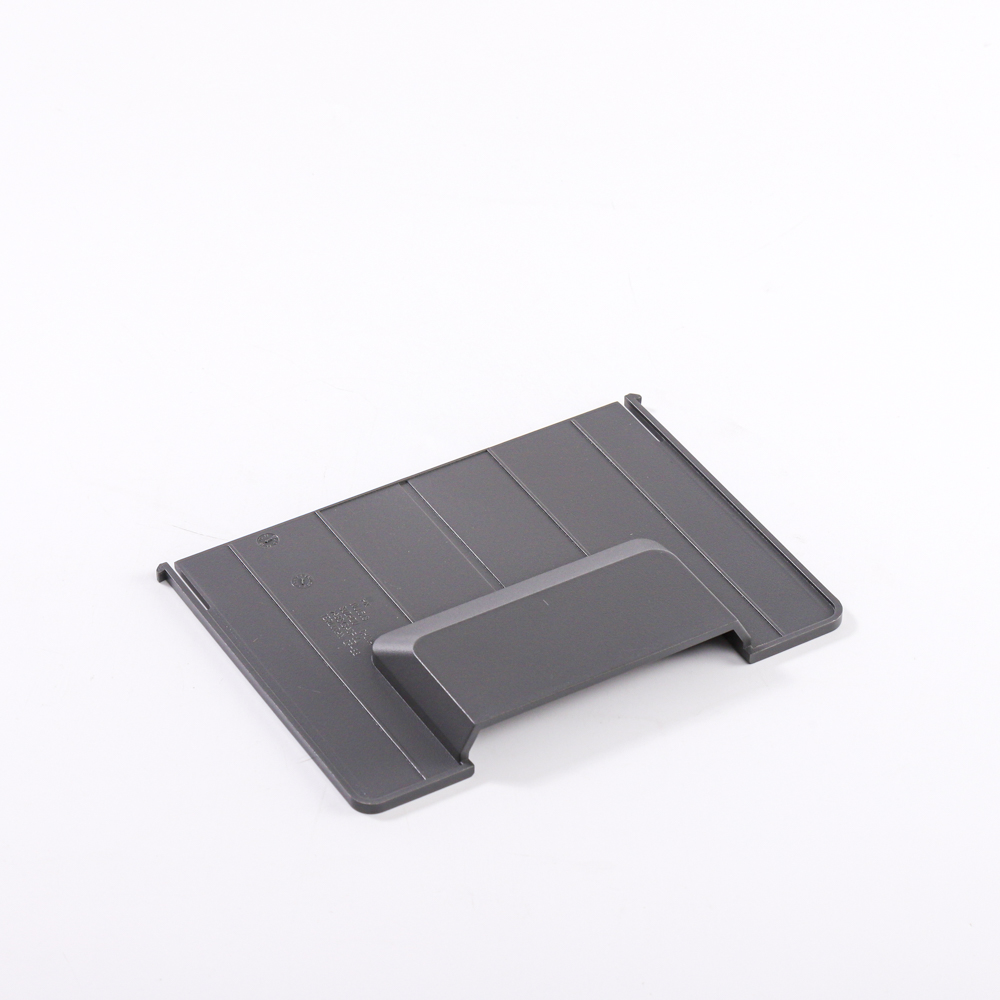

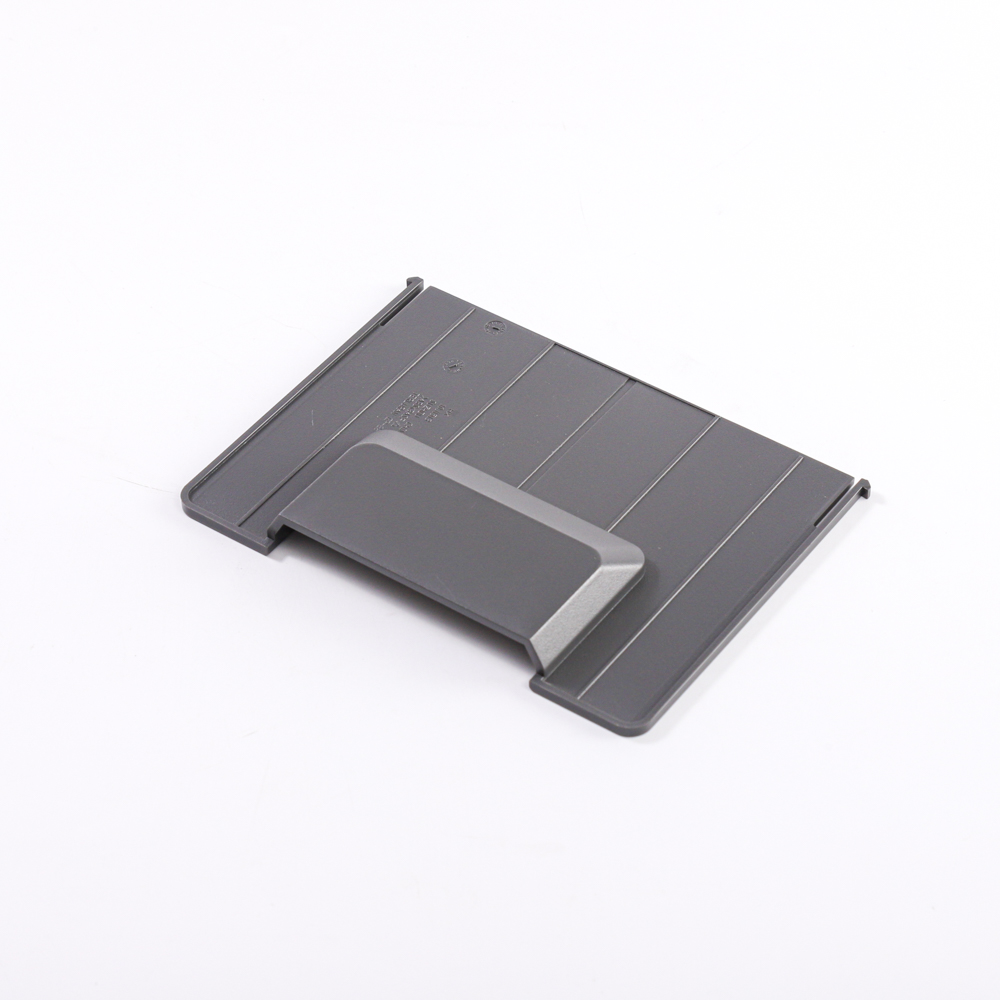

Medical Plastic Injection Molding Parts

- Min. Order:

- 1000 Piece/Pieces

- Min. Order:

- 1000 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000000 |

| Supply Ability: | 1000000 |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

Medical Injection Molding

With the rapid development of science and technology, the use of plastic in modern medicine is steadily increasing. Medical devices made from injection-molded plastic can help reduce healthcare costs, infectious diseases and pain management. High-tech polymers are used in medical device prototyping and are often used to make improved prosthetics and devices that reduce the risk of infection. Medical plastic injection molding directly improves patient safety and the ability to save more lives. The manufacture of medical components and devices using durable, reliable, and FDA-compliant medical grade plastic materials is the essence of medical injection molding. The medical plastic injection molding process is cost effective, ideal for high volume production runs and applications requiring consistency and tight tolerances. This molding process is also used in medical device prototype development, for the FDA approval process and for laboratory testing. Our medical device plastic and medical device prototype development is among the best in China.

Suzhou Precision Molding Co., Ltd. customized size cutting, engineering plastic processing, high wear resistance, good toughness, high in printing, customer service communication inform processing requirements, we will quickly give you a quote, customers confirm the quote after placing an order, product processing is completed, packaging logistics arrangement is completed, customers confirm receipt of goods. Versatile, durable, we only do high quality plastic accessories. There are a variety of models and specifications, according to the drawings customized, factory direct price is more favorable, a variety of material specifications complete, from design to processing, we cover everything, professional customer service, to provide you with the best solution.

Our main products are OEM plastic injection mold parts, precision injection molding, used for Marine industry plastic parts, plastic injection parts, plastic injection parts, injection molding, pp injection parts, Customize Plastic Injection Molding Parts,Plastic Injection Molding Medical Parts,Abs Plastic Injection Molding Parts, etc.

Since medical device plastics provide increased versatility and can be combined with metal to create enhanced medical product attributes, medical grade plastics have become the preferred material for numerous types of electronic medical devices. Some of the advantages that medical injection molding companies can provide, include:

- Improved ergonomics

- Reduced weight

- Increased functionality

- Lower cost

-

Decreased burden of sterilization

Related Keywords