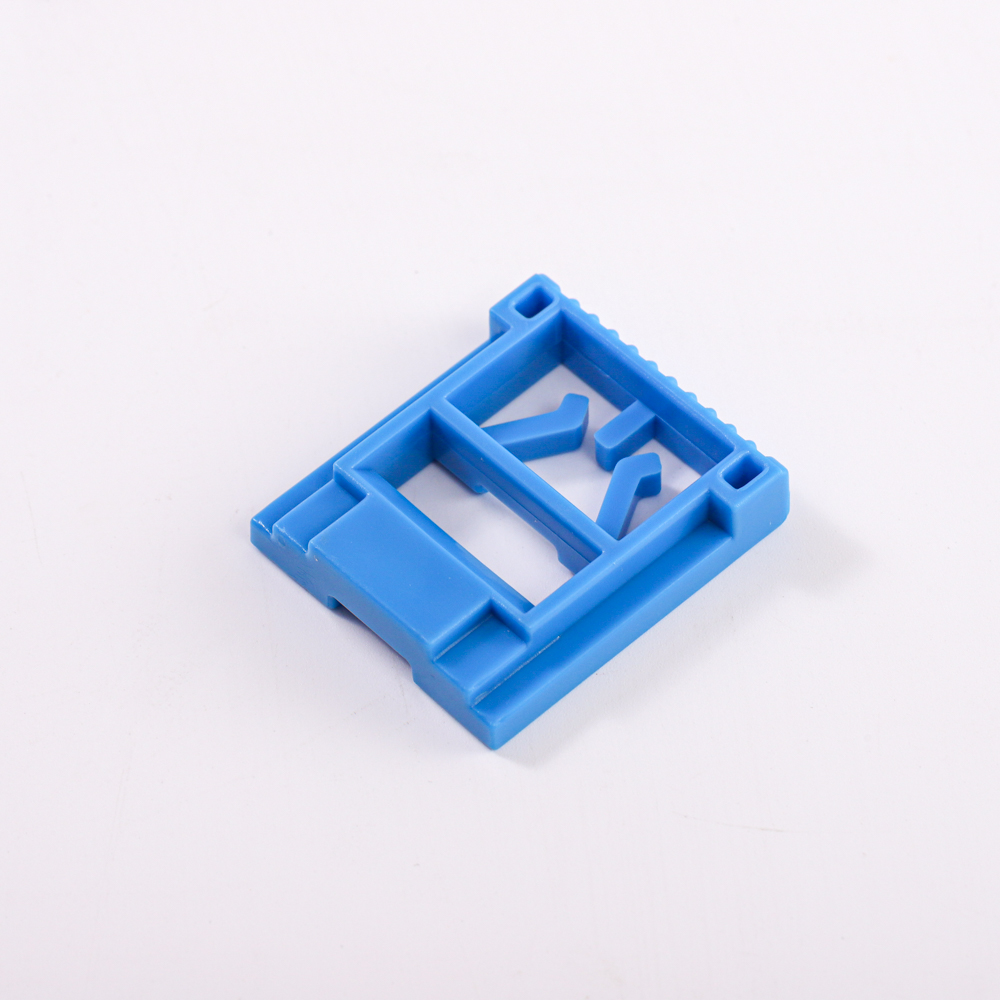

OEM plastic accessories car parts mould

- Min. Order:

- 100 Piece/Pieces

- Min. Order:

- 100 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000000 |

| Supply Ability: | 1000000 |

| Payment Type: | T/T,L/C |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

Plastic accessories car parts moulds are used to manufacture various plastic parts used in automobiles such as bumpers, dashboards, door panels, fenders, grilles, and many more. These moulds are designed to produce high-quality parts that meet the specific requirements of the automotive industry.

The process of making plastic accessories car parts moulds involves several steps. First, the design of the part is created using computer-aided design (CAD) software. Once the design is finalized, a prototype is created using a 3D printing process or by machining the part from a block of material.

After the prototype is tested and approved, the mould is created using a CNC machine. The mould is made from high-quality steel or aluminum and is designed to withstand the high pressure and temperature required for the injection molding process.

The plastic material is then injected into the mould under high pressure and temperature. The plastic cools and solidifies inside the mould, taking on the shape of the desired part. The mould is then opened, and the finished part is removed.

Plastic accessories car parts moulds are essential in the automotive industry as they allow for the mass production of high-quality parts that are consistent in size and shape. This reduces the cost of production and ensures that the parts meet the strict safety and quality standards required in the industry. Inverter Plastic Accessories

Suzhou dongye precision molding co., LTD., mainly engaged in precision connector mold parts, auto connector mold parts, precision plastic mold, precision connector mold parts, precision molds, precision tungsten steel parts, precision molds, precision plastic mold, die-casting mold parts, cause mould parts, PG optical grinding, precision stamping die parts, precision circle and so on, welcome to buy. Inverter plastic parts and other precision parts injection molding accessories products have a variety of specifications, can be customized according to the drawings, and the price is more favorable factory direct sales, variety, from design to processing, packaging, professional after-sales service, to provide you with the best box. Multi-industry application range, automotive industry, electronics industry, aerospace industry, communications industry, medical industry, inverter plastic parts and so on. Experienced, precision abrasive, fast delivery, raw material optimization, no worries after sale. Mechanized production equipment, special-shaped non-standard customization, wear-resisting material, fine workmanship, magnifying details, no noise reduction, no chain hopping sound, long service life.

Related Keywords