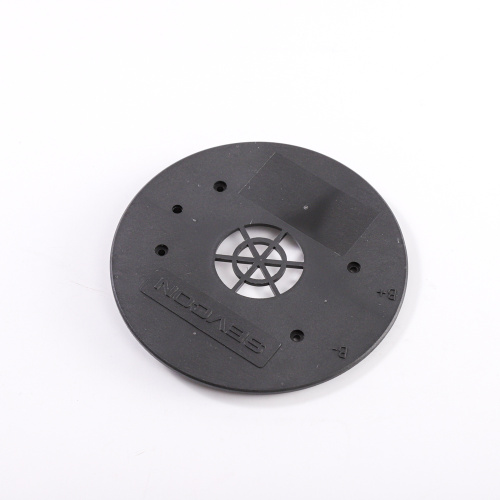

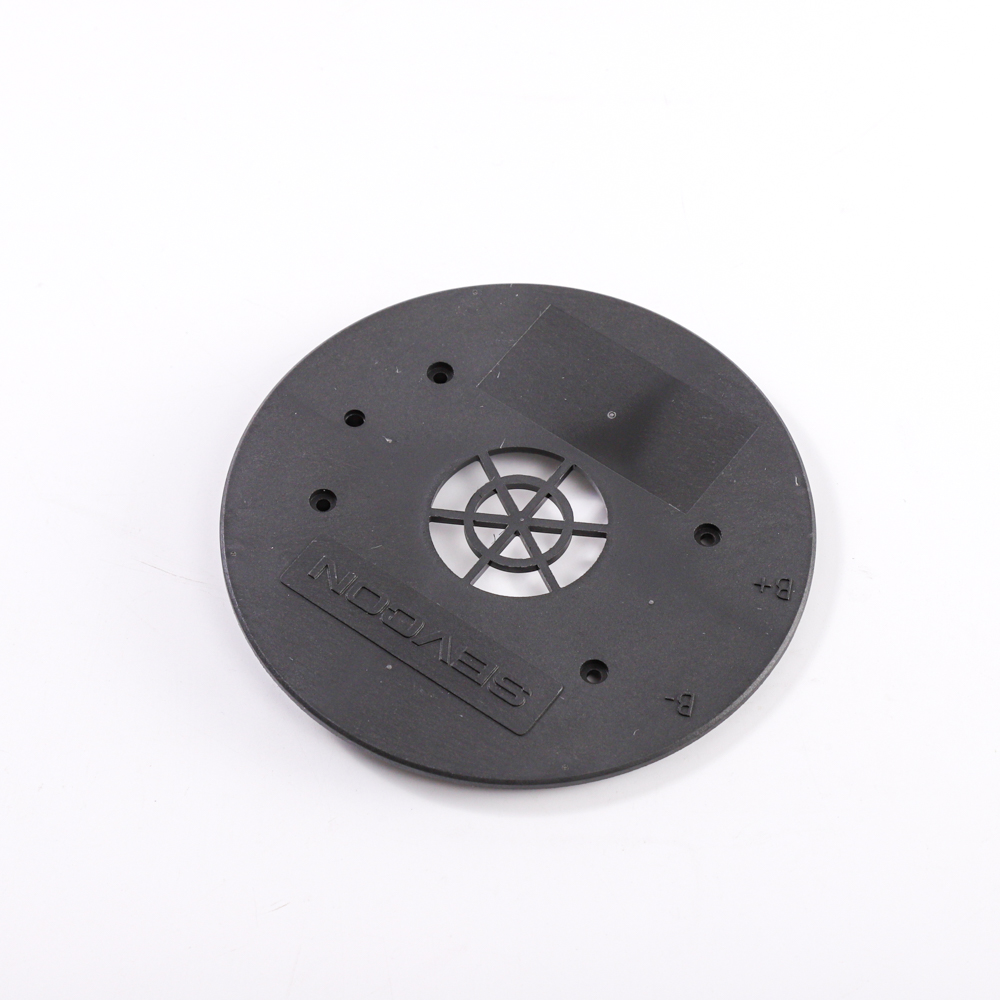

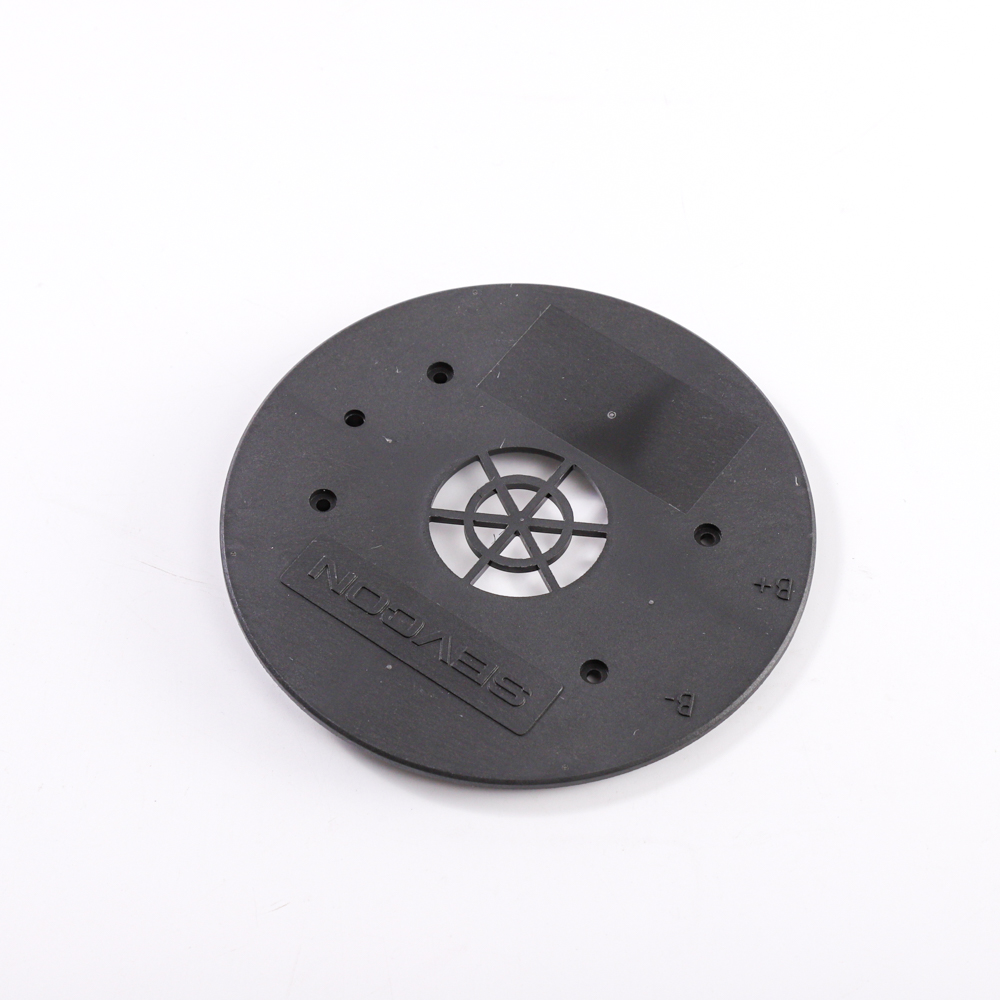

Injection plastic mold design

- Min. Order:

- 1000 Piece/Pieces

- Min. Order:

- 1000 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 1000000 |

| Supply Ability: | 1000000 |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

Product Description

Product Description

Suzhou Precision Molding Co., Ltd. customized size cutting, engineering plastic processing, high wear resistance, good toughness, high in printing, customer service communication inform processing requirements, we will quickly give you a quote, customers confirm the quote after placing an order, product processing is completed, packaging logistics arrangement is completed, customers confirm receipt of goods. Versatile, durable, we only do high quality plastic accessories. There are a variety of models and specifications, according to the drawings customized, factory direct price is more favorable, a variety of material specifications complete, from design to processing, we cover everything, professional customer service, to provide you with the best solution.

Do you offer design services? Absolutely. We have helped countless customers from Europe and North America invent their new products. Our experienced engineers give our customers useful advice to help them solve the problems they encounter when designing and machining molds and products.

Our company's main products are OEM plastic injection mold parts, precision injection molding, used for Marine industry plastic parts, injection parts, plastic injection parts, injection molding, pp injection parts, ABS injection parts, transmission plastic parts, pet plastic parts, toy injection parts, etc.

The application of plastic mold:

Household utility ware

Auto parts

Computer and electronic products

Electronic component

Sales sample

Medical and dental products

Model shops, toys, hobbies

New product design and development

Furniture design

Civil engineering

Garden products

Description:

Short cycle time:

We will design the best cooling system for uniform cooling of plastic molds including: cushion, spring and beryllium copper cooling system. The cooling system mainly determines the cost of the parts.

Quality control:

1. Quality control of incoming materials: inspect all steel and purchased standard parts to ensure that they meet the requirements of customized plastic molds;

2. In terms of process quality control: all processing and assembly processes are under control. We have a QC team to check and supervise whether tolerances and machined surfaces meet the requirements;

3. Final quality control: After the plastic mold is completed, we will thoroughly check the plastic sample and the main size of the mold to ensure that every step is not ignored and the quality of the plastic mold is ok.

Process steps:

a. Provide competitive prices according to customer's detailed requirements

b. Sign an agreement

c. The customer telegraphic deposit to us to start designing the mold

d. Send the mold drawing to the customer for confirmation

e. Confirm mold design and start making molds

f. Conduct mold trials during mold processing (reach agreement with customer)

g. Send trial samples to customers for inspection. Or customers come to our factory to inspect the mold

h. The customer will send us by telegraphic transfer after mold confirmation

i. Balance after the mold

We provide:

Multi-cavity die

Home mold

Hot runner mold

Rapid prototyping

Plastic molding

assemble

Secondary operation

Competitive advantage:

1. The company has successfully passed iso9001 quality management system and IGS quality management system certification.

2. We can design and manufacture molds of different specifications and standards, such as DME,HASCO and DAIDO.

3. Our factory is equipped with the most advanced testing instruments, effectively ensure the accuracy of the mold.

4. Strict quality control;

5. Good after-sales service;

6. Deliver on time

Do you offer design services? Absolutely. We have helped countless customers from Europe and North America invent their new products. Our experienced engineers give our customers useful advice to help them solve the problems they encounter when designing and machining molds and products.

Our company's main products are OEM plastic injection mold parts, precision injection molding, used for Marine industry plastic parts, injection parts, plastic injection parts, injection molding, pp injection parts, ABS injection parts, transmission plastic parts, pet plastic parts, toy injection parts, etc.

The application of plastic mold:

Household utility ware

Auto parts

Computer and electronic products

Electronic component

Sales sample

Medical and dental products

Model shops, toys, hobbies

New product design and development

Furniture design

Civil engineering

Garden products

Description:

Short cycle time:

We will design the best cooling system for uniform cooling of plastic molds including: cushion, spring and beryllium copper cooling system. The cooling system mainly determines the cost of the parts.

Quality control:

1. Quality control of incoming materials: inspect all steel and purchased standard parts to ensure that they meet the requirements of customized plastic molds;

2. In terms of process quality control: all processing and assembly processes are under control. We have a QC team to check and supervise whether tolerances and machined surfaces meet the requirements;

3. Final quality control: After the plastic mold is completed, we will thoroughly check the plastic sample and the main size of the mold to ensure that every step is not ignored and the quality of the plastic mold is ok.

Process steps:

a. Provide competitive prices according to customer's detailed requirements

b. Sign an agreement

c. The customer telegraphic deposit to us to start designing the mold

d. Send the mold drawing to the customer for confirmation

e. Confirm mold design and start making molds

f. Conduct mold trials during mold processing (reach agreement with customer)

g. Send trial samples to customers for inspection. Or customers come to our factory to inspect the mold

h. The customer will send us by telegraphic transfer after mold confirmation

i. Balance after the mold

We provide:

Multi-cavity die

Home mold

Hot runner mold

Rapid prototyping

Plastic molding

assemble

Secondary operation

Competitive advantage:

1. The company has successfully passed iso9001 quality management system and IGS quality management system certification.

2. We can design and manufacture molds of different specifications and standards, such as DME,HASCO and DAIDO.

3. Our factory is equipped with the most advanced testing instruments, effectively ensure the accuracy of the mold.

4. Strict quality control;

5. Good after-sales service;

6. Deliver on time

Related Keywords

Related Keywords