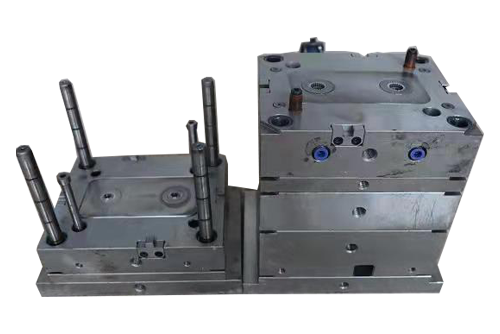

custom plastic parts mold design services

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000000 |

| Supply Ability: | 1000000 |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

Suzhou Dongye Precision Molding Co., LTD can make moulds according to DME HASCO standard. The company has excellent and rich design ability and software (UG, ProE, Solidworks, Catia, etc.) complete processing equipment, strict quality control system, can fully meet the needs of customers. Injection mold is one of our main business, our company also can professionally produce all kinds of injection mold. Our plastic injection molding can be made from most plastics including PP/ABS/PC /PA/PBT/POM etc. Injection molding is an extremely versatile process used to produce a wide variety of simple or complex plastic parts with excellent finish that can achieve almost any 2D or 3D shape. All plastic products can be produced from molds. We can make molds for customers, low cost, high quality products. Seeger mold provides services for the entire project development, including design, mold manufacturing, plastic parts production and after-sales service.

Injection Tooling & Mold Design

1. Part design: The first step is to design the plastic part that needs to be molded. This includes determining the size, shape, and material of the part.

2. Mold design: Once the part design is finalized, the mold design can be created. This involves determining the size and shape of the mold, as well as the number of cavities needed to produce the desired quantity of parts.

3. Mold material selection: The mold material needs to be chosen based on the material of the part and the expected number of cycles the mold will be used for.

4. Mold flow analysis: A mold flow analysis is performed to ensure that the mold design will produce parts that meet the required specifications.

5. Mold fabrication: The mold is fabricated based on the design and material specifications.

6. Mold testing: The mold is tested to ensure that it produces parts that meet the required specifications.

7. Production: Once the mold is tested and approved, it can be used for production of the plastic parts.

Related Keywords