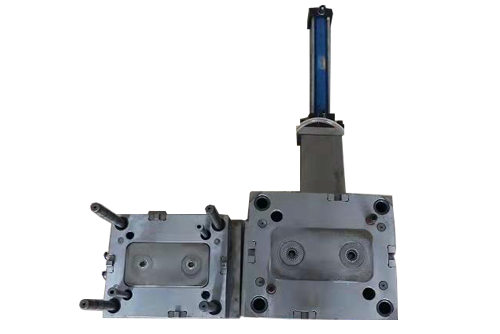

ABS injection small plastic parts mold maker

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000000 |

| Supply Ability: | 1000000 |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

Plastic Injection Mold The heat balance control of injection molding machine and mold injection mold heat transfer is the key to the production of injection molded parts.Mold, made of plastic (such as thermoplastic) bring heat by thermal radiation is passed to the materials and mould steel, through to the passed thermal fluid.In addition, the heat by thermal radiation is passed to the atmosphere and die set.Heat absorbed by the thermal fluid by the mold temperature machine to take away.Mould thermal equilibrium can be described as: P = Pm - Ps.Type in the P for mold temperature machine away heat;Pm for plastic into heat;Ps mould emanate heat into the atmosphere.Control of mold temperature and mold temperature on the influence of plastic injection molding process, mold temperature is the main purpose of a control is to move the mould heated to working temperature, mold temperature constant temperature at work.The above two points do succeed, can put the cycle time optimization, thus to ensure a stable high quality of injection molded parts.Mold temperature will affect the surface quality, liquidity, shrinkage rate, injection molding cycle and deformation and so on.Mold temperature is too high or inadequate will bring different influence on different materials.For thermoplastic, high mold temperature first whiff can improve the surface quality and liquidity, but will prolong cooling and injection molding cycle.Within the lower mold temperature, decreases in the mold shrinkage, but increases after demoulding shrinkage of injection molded parts.And for thermosetting plastics, higher mold temperature usually reduce cycle time, and time is determined by the parts required for cooling time.In addition, in the plastic processing, higher mold temperature will reduce the plasticizing time, reduced cycle times.

Related Keywords