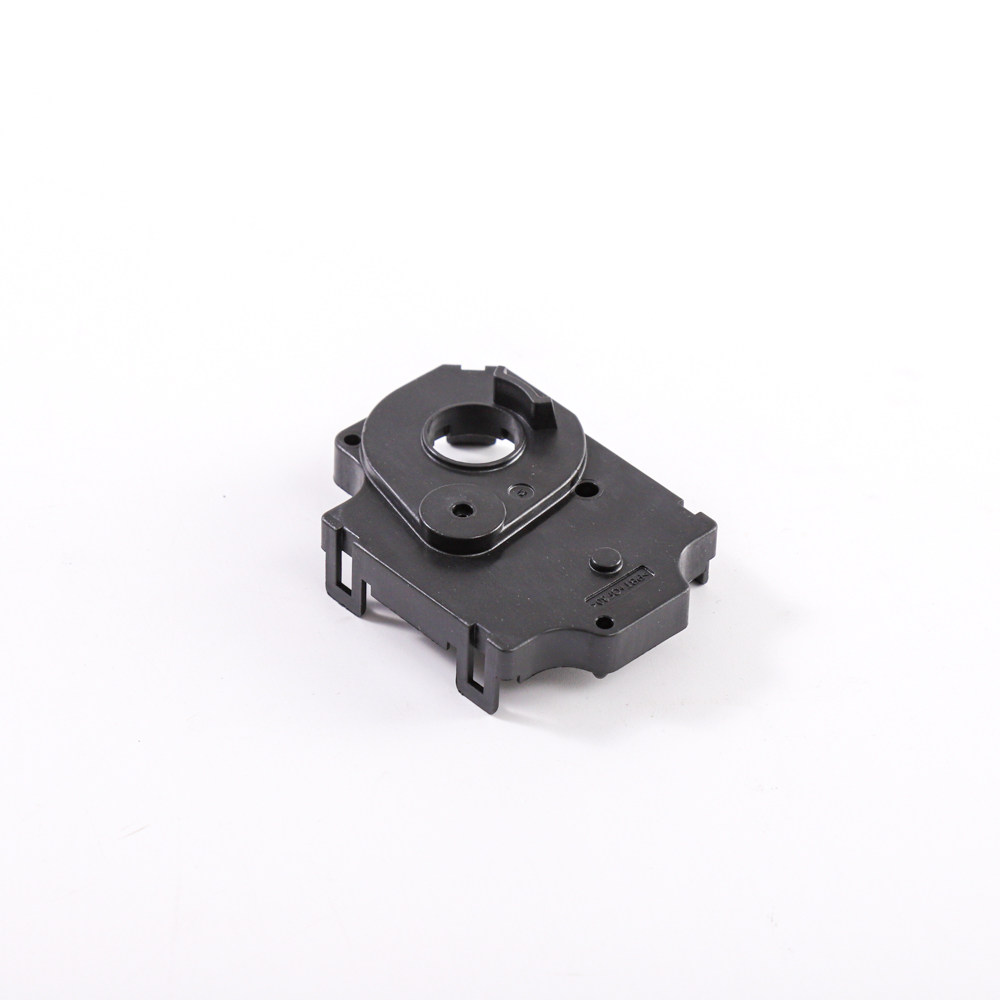

wholesale Home Appliances Injection Molding Parts

- Min. Order:

- 1000 Piece/Pieces

- Min. Order:

- 1000 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000000 |

| Supply Ability: | 1000000 |

| Payment Type: | T/T,L/C |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

What is injection molding?

Injection molding is a manufacturing technique for mass production of identical plastic parts with good tolerances. In injection molding, polymer particles are first melted and then injected under pressure into a mold, where the liquid plastic cools and solidifies. The materials used in injection molding are thermoplastic polymers that can be colored or filled with other additives.

Almost every plastic part around you is made by injection molding: from car parts to electronic housings to injection molded parts for home appliances.

Injection molding is so popular because its unit cost is so low when it is produced in large quantities. Injection molding has high repeatability and good design flexibility. The main limitation of injection molding usually comes down to economy, as the mold requires a high initial investment. In addition, the turnaround time from design to production is slow (at least 4 weeks).

Related Keywords