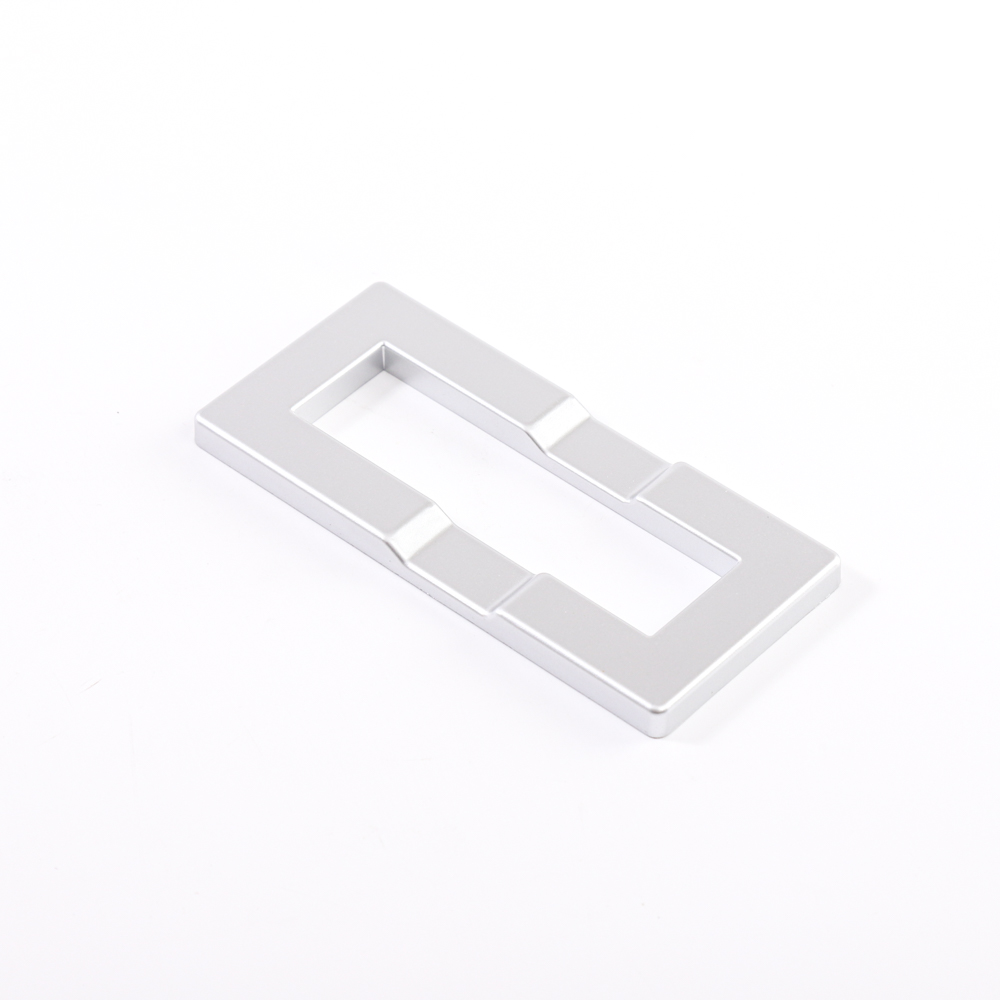

Customized High Quality Plastic Injection Moulding

- Min. Order:

- 1000 Piece/Pieces

- Min. Order:

- 1000 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000000 |

| Supply Ability: | 1000000 |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

Our company is a professional production of plastic mold, and plastic injection products of the enterprise. We specialise in the manufacture of custom precision machined plastic components - to your exact specifications. We have a wide range of CNC machining equipment to meet your complex machining needs. We also have traditional plastic processing facilities to produce high quality plastic components at competitive prices. You need to send us 2D or 3D drawings or samples. Then we can quote you exactly as you requested. Hot runner or cold runner can be selected according to customer requirements. What kind of mold do we have? Humidifier shell Injection mold, humidifier shell precision injection mold, knife sharpener shell injection mold, etc. What material is this mold made of? We commonly used die steel :S45C, S50C, P20, S136H, 718, 718H, 2738, 2316, 2083, 2311, NAK80, H13 and so on. What software does our company use for mold design, product design and CNC programming? Mold design using UG, Proe, AutoCAD, Solidworks and other software. For CNC programming, we use powerMill. When is the delivery date of the first sample? The delivery time for the first sample is usually 35 days. The company also has a wide range of injection molding products, the main products are mobile phone shell, refrigerator glue rack, projection TV back shell, plastic light box, plastic words, plastic bags, plastic cups, car dashboard accessories, seat back accessories, car door accessories, toy car shell and so on.

Electronic Plastic Parts,Electronic plastic refers to a type of plastic material that has electrical and electronic properties. These plastics are used in a variety of electronic devices and equipment, such as computer components, mobile phones, and other electronic appliances.

Electronic plastics are designed to have specific properties, such as high heat resistance, low dielectric constant, and good electrical insulation. They are also lightweight, durable, and cost-effective, making them an ideal choice for use in electronic devices.

Some common types of electronic plastics include polycarbonate, polyethylene, polypropylene, and polyvinyl chloride (PVC). These plastics are often used in the manufacturing of electronic components, such as circuit boards, connectors, and housings.

Overall, electronic plastics play a critical role in the development and production of modern electronic devices, helping to ensure that they are lightweight, durable, and able to withstand the demands of everyday use.

Related Keywords