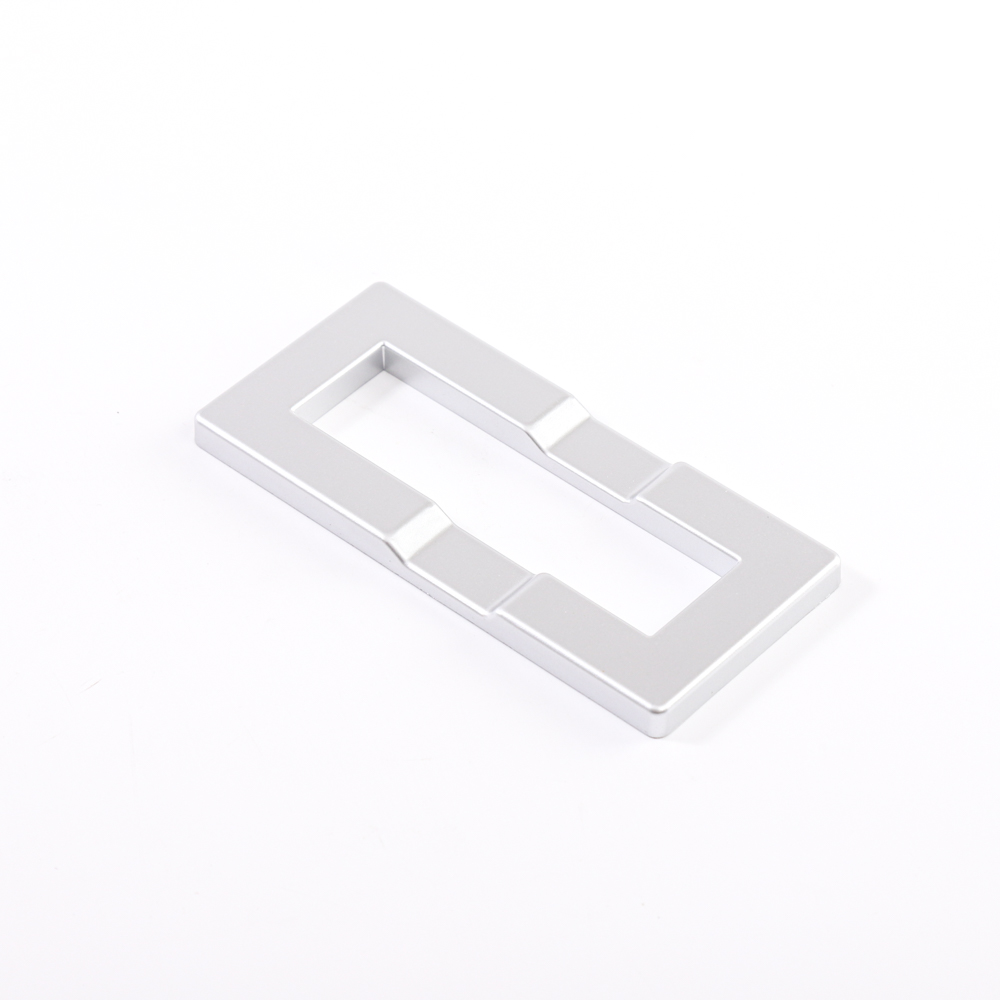

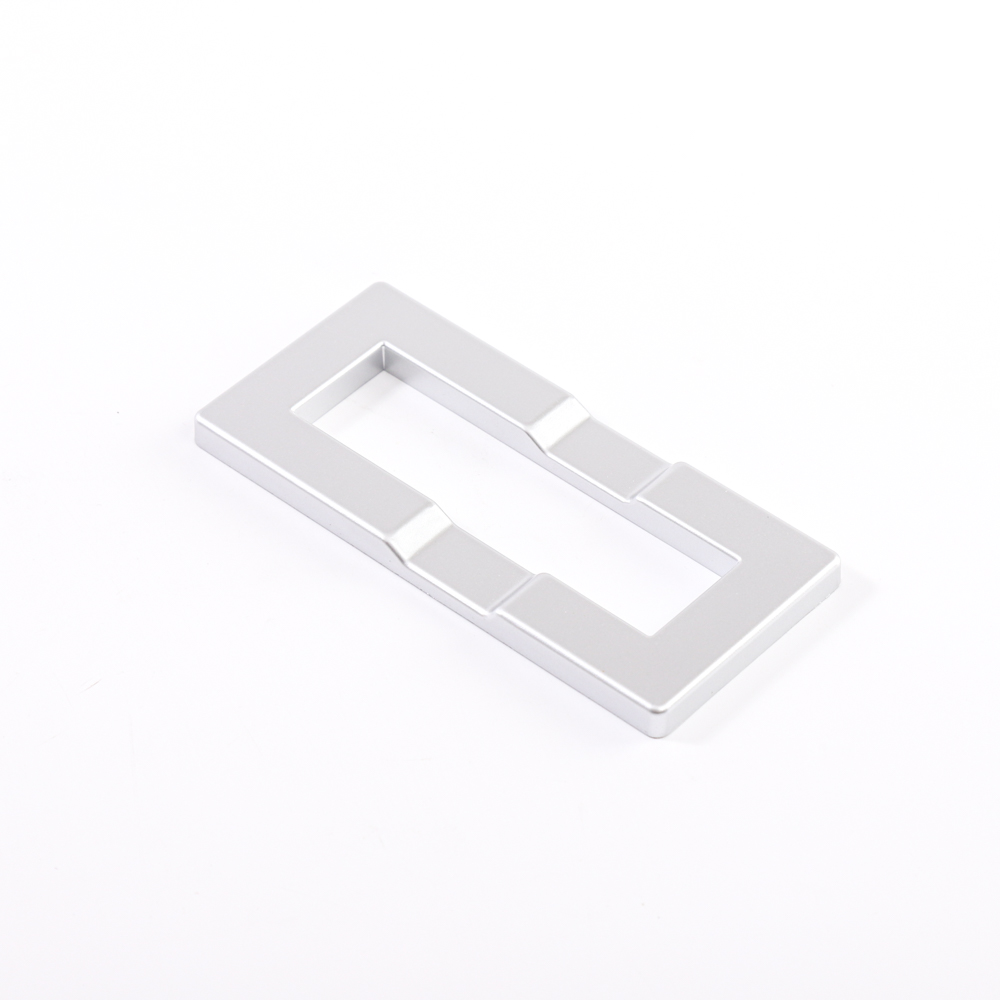

Precision Custom Plastic Parts

- Min. Order:

- 1000 Piece/Pieces

- Min. Order:

- 1000 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 10000000 |

| Supply Ability: | 1000000 |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

Product Description

Product Description

Professional injection molding customized injection mold

1. Reasonable price

2. Make plastic bottle handle mold

3. Plastic injection mold

4. Plastic parts mold

5.1) Mold base :LKM brand, Shanghai Haihua Ship, etc.2) Cavity/core material :DIN1.2344, 738H, 718,8407,S136, NAK80, P20, SKD-61, NIMAX, etc. 3) Number of cavities: single/multiple cavities. 4) Delivery time: 25-50 days, according to different products 5) Quality assurance: 500,000-1,000,000 times, according to customer requirements 6) Product material :PP, PA, POM, ABS, PET, PC, PE, HDPE, PA66 + GF, PVC, Hills, etc. 7) Hot Runner: Hashigh,YUDO, Ranging Device, MolD-Master 8) Color Standard: Pantone Color Card, Culture, 9) Texture :VDI, Y 10) Price Conditions: according to customer requirements. 11) Packing: wooden case, plastic, color box, carton or packing according to customer requirements.

Our R & D manufacturing services are ideal for customers to design new parts or products. We can make prototypes and short runs that allow you to check that the design criteria are met and that full functionality is implemented in the finished product.

After you have made any necessary changes to your design, we will adjust our molding and tools to create products that incorporate these adjustments. We work closely with several quality tool and die manufacturers to help us create injection molded parts that will exactly match your specifications in any number of design iterations.

What is the product line of our company? Injection MOLDING DESIGN/manufacturing, INDUSTRIAL design, Injection molding, PLASTIC parts production. What certificates do you have? SGS iso9001:2008. How do we make sure you build the right mold for us? To avoid misunderstanding, we will provide DFM report (including parting line, top pin position, thickness, drawing, etc.) and die structure for you to check the project details before modeling. The fourth quarter. What if we want to make some changes? If the size is not within the tolerance of the drawing, we will modify the mold free of charge. If you have new requirements after sampling, we will give you some modification methods, such as A and B, you can choose, but the last one we modified can't meet your requirements, we will use B to modify the mold for free. How to ensure injection mold delivery on time? We will send mold processing pictures, parts size measurement report, parts samples and mold videos to you for details every week. Our quality assurance? We use 2 d, 3 D size measuring machine to inspect the mold and plastic parts from beginning to end. So far. How do I order from us? Inquiry, QUOTATION - ORDER, DEPOSIT - MOULD AND PARTS CONFIRMATION - INJECTION MOULD MAKING TI SAMPLE - INJECTION PARTS CONFIRMATION - BALANCE/DELIVERY, CUSTOMER FEEDBACK AND FURTHER COOPERATION SOLUTIONS. The disposal. How do I pay? Telegraphic transfer, letter of credit, Western Union, etc.

1. Reasonable price

2. Make plastic bottle handle mold

3. Plastic injection mold

4. Plastic parts mold

5.1) Mold base :LKM brand, Shanghai Haihua Ship, etc.2) Cavity/core material :DIN1.2344, 738H, 718,8407,S136, NAK80, P20, SKD-61, NIMAX, etc. 3) Number of cavities: single/multiple cavities. 4) Delivery time: 25-50 days, according to different products 5) Quality assurance: 500,000-1,000,000 times, according to customer requirements 6) Product material :PP, PA, POM, ABS, PET, PC, PE, HDPE, PA66 + GF, PVC, Hills, etc. 7) Hot Runner: Hashigh,YUDO, Ranging Device, MolD-Master 8) Color Standard: Pantone Color Card, Culture, 9) Texture :VDI, Y 10) Price Conditions: according to customer requirements. 11) Packing: wooden case, plastic, color box, carton or packing according to customer requirements.

Our R & D manufacturing services are ideal for customers to design new parts or products. We can make prototypes and short runs that allow you to check that the design criteria are met and that full functionality is implemented in the finished product.

After you have made any necessary changes to your design, we will adjust our molding and tools to create products that incorporate these adjustments. We work closely with several quality tool and die manufacturers to help us create injection molded parts that will exactly match your specifications in any number of design iterations.

What is the product line of our company? Injection MOLDING DESIGN/manufacturing, INDUSTRIAL design, Injection molding, PLASTIC parts production. What certificates do you have? SGS iso9001:2008. How do we make sure you build the right mold for us? To avoid misunderstanding, we will provide DFM report (including parting line, top pin position, thickness, drawing, etc.) and die structure for you to check the project details before modeling. The fourth quarter. What if we want to make some changes? If the size is not within the tolerance of the drawing, we will modify the mold free of charge. If you have new requirements after sampling, we will give you some modification methods, such as A and B, you can choose, but the last one we modified can't meet your requirements, we will use B to modify the mold for free. How to ensure injection mold delivery on time? We will send mold processing pictures, parts size measurement report, parts samples and mold videos to you for details every week. Our quality assurance? We use 2 d, 3 D size measuring machine to inspect the mold and plastic parts from beginning to end. So far. How do I order from us? Inquiry, QUOTATION - ORDER, DEPOSIT - MOULD AND PARTS CONFIRMATION - INJECTION MOULD MAKING TI SAMPLE - INJECTION PARTS CONFIRMATION - BALANCE/DELIVERY, CUSTOMER FEEDBACK AND FURTHER COOPERATION SOLUTIONS. The disposal. How do I pay? Telegraphic transfer, letter of credit, Western Union, etc.

Related Keywords

Related Keywords