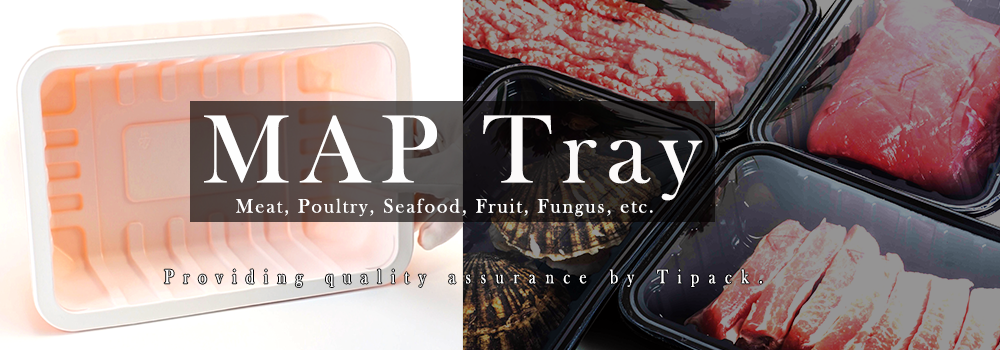

MAP Technology Food Packaging Gas Packaging

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shanghai, Ningbo, Yiwu

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1,000,000pcs per month |

| Supply Ability: | 1,000,000 Pcs per month |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Money Gram,Western Union |

| Incoterm: | DAF,Express Delivery,DDU,DDP,DEQ,CIP,CPT,FCA,FAS,EXW,CIF,CFR,FOB |

| Certificate: | ISO 9001:2015 |

| HS Code: | 3923100090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai,Ningbo,Yiwu |

Precautions for using modified atmosphere packaging

(1) Processing of fresh meat before packaging. If the pork is cooled at 0℃-4℃ for 24h after slaughtering, the acid excretion process will occur after the ATP stops moving. The chiled meat treated in this way has far better nutrition and taste than quick-frozen meat and hot fresh meat. In addition, in order to ensure the preservation effect of modified atmosphere packaging, it is also necessary to control the hygienic indicators of fresh meat before packaging to prevent microbial contamination.

(2) Selection of packaging materials. Fresh Meat MAP Trays should use packaging materials with good barrier properties to prevent gas leakage in the packaging and at the same time prevent the infiltration of oxygen in the atmosphere. Composite packaging films such as PET, PP, PA, and PVDC are usually used as the base material. To measure the gas barrier properties of plastic films, it is generally expressed by the air permeability coefficient: the smaller the air permeability coefficient, the better the barrier properties. In addition, all packaging materials must have sufficient mechanical strength to withstand pressure changes during vacuum. At the same time, the material is also required to have a certain stiffness so that the packaging bag can be automatically opened and inflated.

(3) Control of product storage temperature. The influence of temperature on the preservation effect comes from two aspects: one is that the temperature directly affects the activities of various microorganisms on the surface of the body; the other is that the barrier properties of packaging materials are closely related to temperature. The higher the temperature, the better the barrier properties of packaging materials. Low. Therefore, it is necessary to realize the temperature control of the whole process from product, storage, transportation to sales.

The use of high barrier Lidding film can further extend the shelf life of the package.

Moreover, Tipack also provides packaging machines for MAP Trays to customers.

Please leave us a message or send an email to get the latest quotation and samples.

Related Keywords