Oxygen Barrier EVOH Heat Shrink Bag for Food

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shanghai, Ningbo, Yiwu

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 100,000 tons per year |

| Supply Ability: | 100,000 tons per year |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DDP,DDU,Express Delivery |

| Certificate: | ISO 9001:2015 |

| HS Code: | 3923290000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai,Ningbo,Yiwu |

Product Description

Product Description

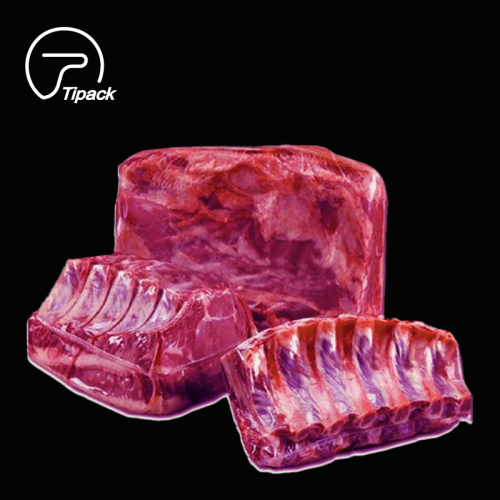

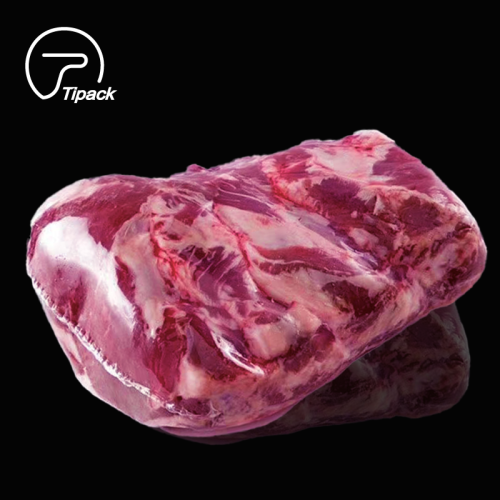

Oxygen Barrier EVOH Heat Shrink Bag is a type of packaging material used for food products that require oxygen protection. EVOH (Ethylene Vinyl Alcohol) is a polymer with excellent oxygen barrier properties, which makes it suitable for use in food packaging applications where the preservation of the product is critical.

The heat shrink bag is designed to shrink and conform to the shape of the product being packaged when exposed to heat. This creates a tight, protective barrier around the product, which helps to preserve its freshness and flavor.

EVOH heat shrink bags are commonly used for packaging fresh or processed meat, cheese, fish, and other perishable food products. The bags can be used for both vacuum packaging and modified atmosphere packaging (MAP), which involves replacing the air inside the package with a specific gas mixture to extend the shelf life of the product.

The use of EVOH in the shrink bag film offers several benefits, including:

1、Excellent oxygen barrier properties: EVOH has an extremely low oxygen permeability rate, which makes it an effective barrier against oxygen transmission. This helps to prevent oxidation and spoilage of the food product.

2、High shrink properties: The heat shrink bag has high shrink properties, which means it conforms tightly to the product being packaged. This provides excellent protection against contamination and extends the shelf life of the product.

3、Clarity: The film used in the heat shrink bag is transparent, which allows consumers to see the product inside.

4、Resistance to punctures and tears: EVOH heat shrink bags are resistant to punctures and tears, which helps to prevent leaks and spoilage.

Overall, EVOH heat shrink bags are an excellent choice for packaging food products that require oxygen protection and extended shelf life.

The heat shrink bag is designed to shrink and conform to the shape of the product being packaged when exposed to heat. This creates a tight, protective barrier around the product, which helps to preserve its freshness and flavor.

EVOH heat shrink bags are commonly used for packaging fresh or processed meat, cheese, fish, and other perishable food products. The bags can be used for both vacuum packaging and modified atmosphere packaging (MAP), which involves replacing the air inside the package with a specific gas mixture to extend the shelf life of the product.

The use of EVOH in the shrink bag film offers several benefits, including:

1、Excellent oxygen barrier properties: EVOH has an extremely low oxygen permeability rate, which makes it an effective barrier against oxygen transmission. This helps to prevent oxidation and spoilage of the food product.

2、High shrink properties: The heat shrink bag has high shrink properties, which means it conforms tightly to the product being packaged. This provides excellent protection against contamination and extends the shelf life of the product.

3、Clarity: The film used in the heat shrink bag is transparent, which allows consumers to see the product inside.

4、Resistance to punctures and tears: EVOH heat shrink bags are resistant to punctures and tears, which helps to prevent leaks and spoilage.

Overall, EVOH heat shrink bags are an excellent choice for packaging food products that require oxygen protection and extended shelf life.

Related Keywords

Related Keywords