EVOH Barrier Vacuum Shrink Bags for Meat Packaging

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shanghai, Ningbo, Yiwu

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100,000 tons per year |

| Supply Ability: | 100,000 tons per year |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,CPT,CIP,DDP,DDU,Express Delivery |

| Certificate: | ISO 9001:2015 |

| HS Code: | 3923290000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai,Ningbo,Yiwu |

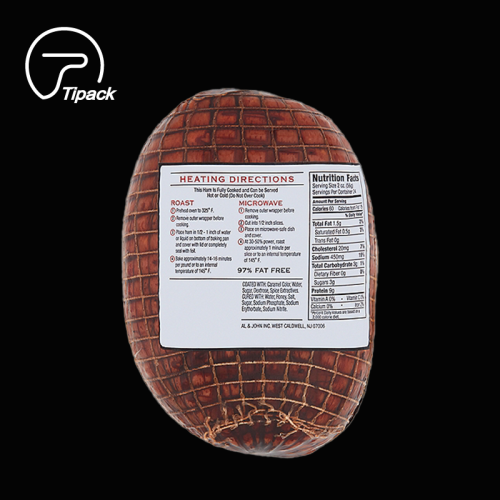

There are different types of packaging materials used in various industries to protect and preserve products. EVOH Shrink Bag and Shrink Film are made with ethylene vinyl alcohol copolymer, which provides excellent oxygen barrier properties. They are often used for packaging fresh meats, cheeses, and other food items. Shrink Bag and film are materials that shrink when heated, which creates a tight and protective seal around the product. Evoh Shrink Vacuum Bag is used for vacuum sealing, which removes air and extends the shelf life of products. Barrier bags are packaging materials that provide a barrier against moisture, oxygen, and other environmental factors that can affect the quality of the product.

Advantages of EVOH (ethylene vinyl alcohol) shrink bags include:

1.Barrier properties:

EVOH has excellent oxygen barrier properties, which can help to extend the shelf life of packaged products.

2.Clarity:

EVOH has good clarity and gloss, which can enhance product presentation and appeal to consumers.

3.Shrink performance:

EVOH can provide good shrink performance, which can help to create an attractive package with a tight, wrinkle-free appearance.

4.Versatility:

EVOH can be used with a variety of packaging equipment and in a range of applications, including meat, cheese, seafood, and other food products.

5.Safety:

EVOH is generally considered to be safe for food packaging applications, and is approved for use by regulatory agencies such as the FDA and the EU.

Related Keywords