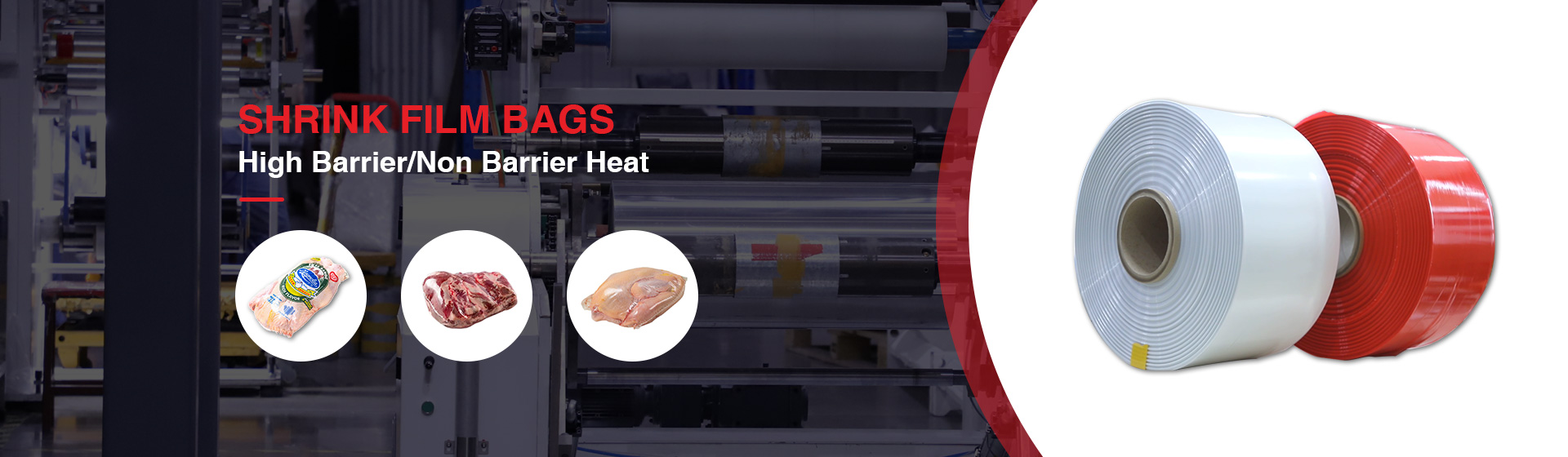

Tipack provides food-grade fresh-keeping packaging solutions for food producers and sellers, including heat shrinkable packaging (Shrink Bag, Shrink Film, Plastic Casing Film, etc.), thermoforming packaging (Thermoforming Film, Map Trays, Vsp Trays, PSP Tray, Fruit Cup, etc.) ), and Plastic Sheets, Lidding Film, Skin Film, Vacuum Bag, Absorbent Pads, K Cup Coffee Capsule, Packaging Machine, etc.

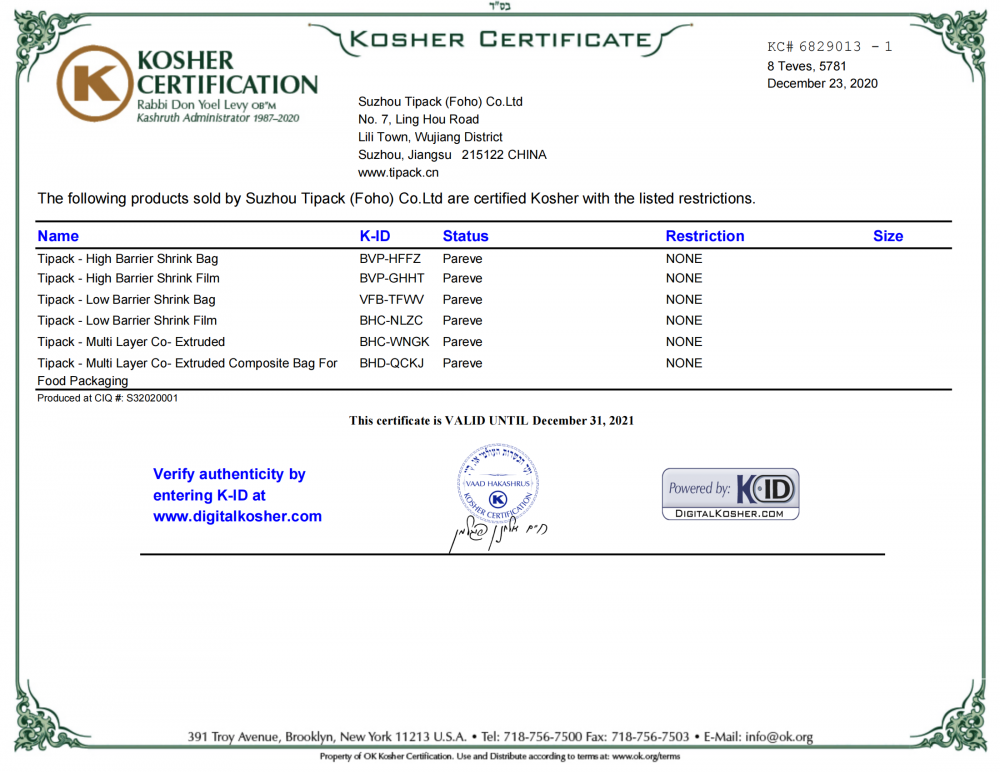

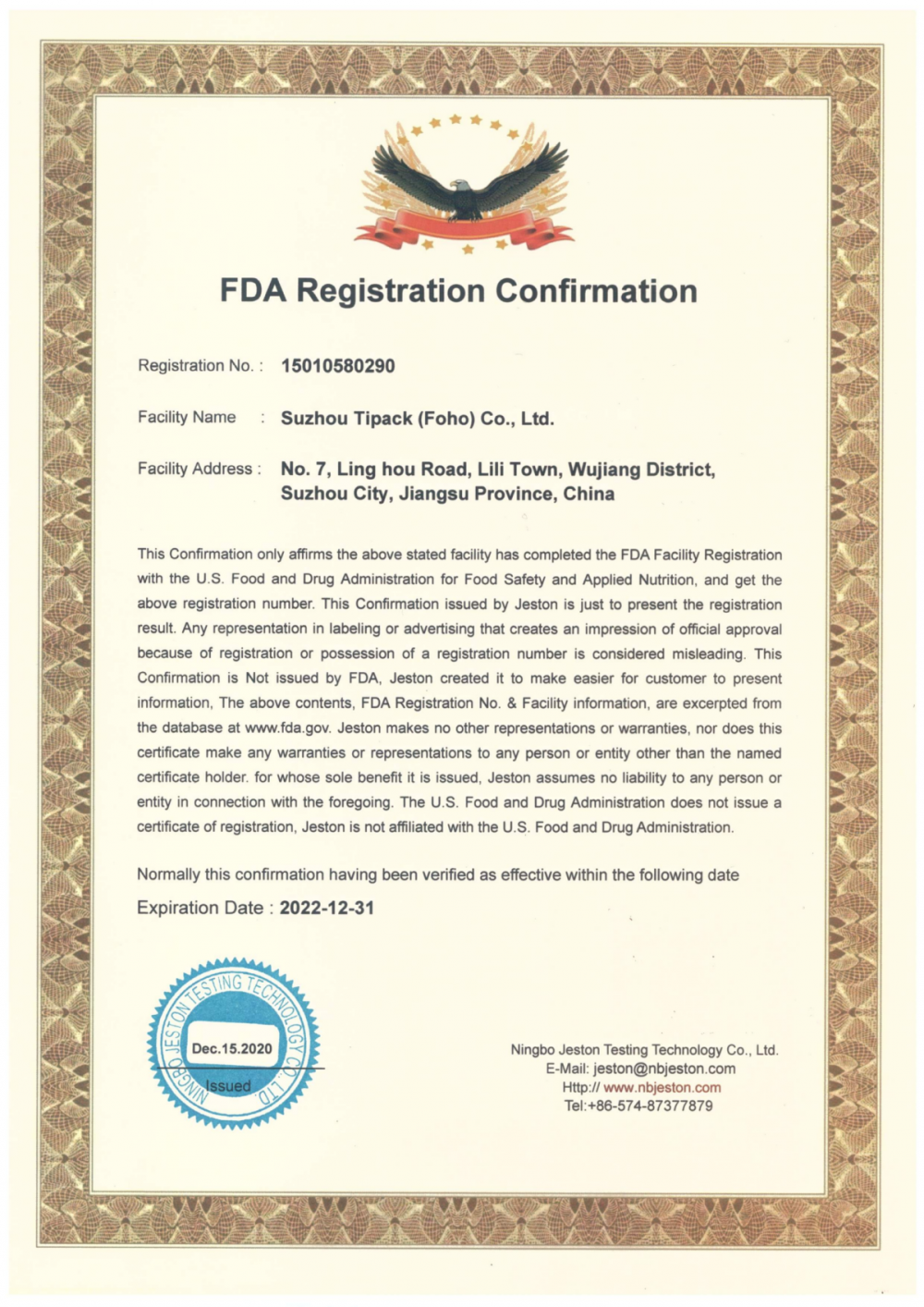

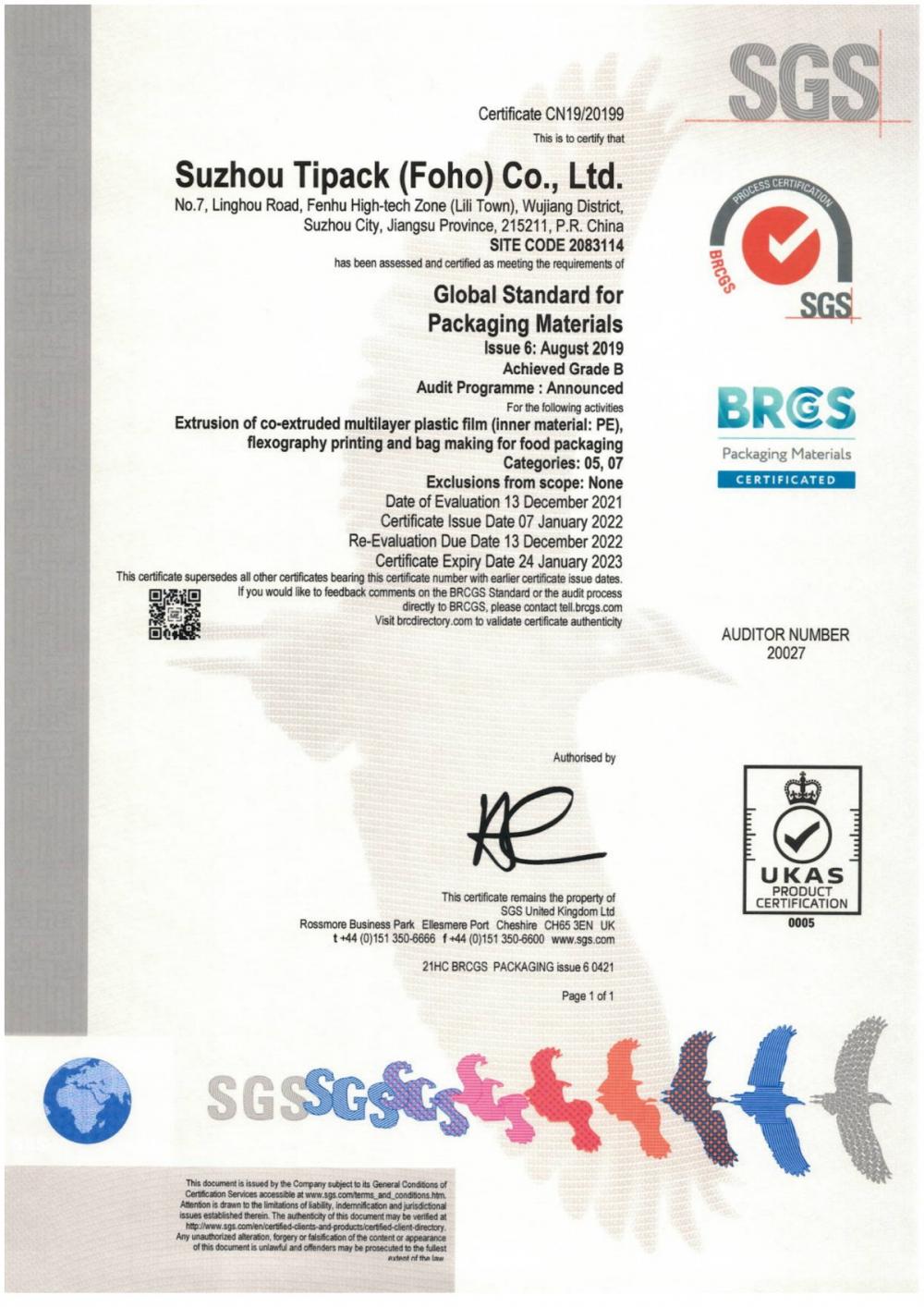

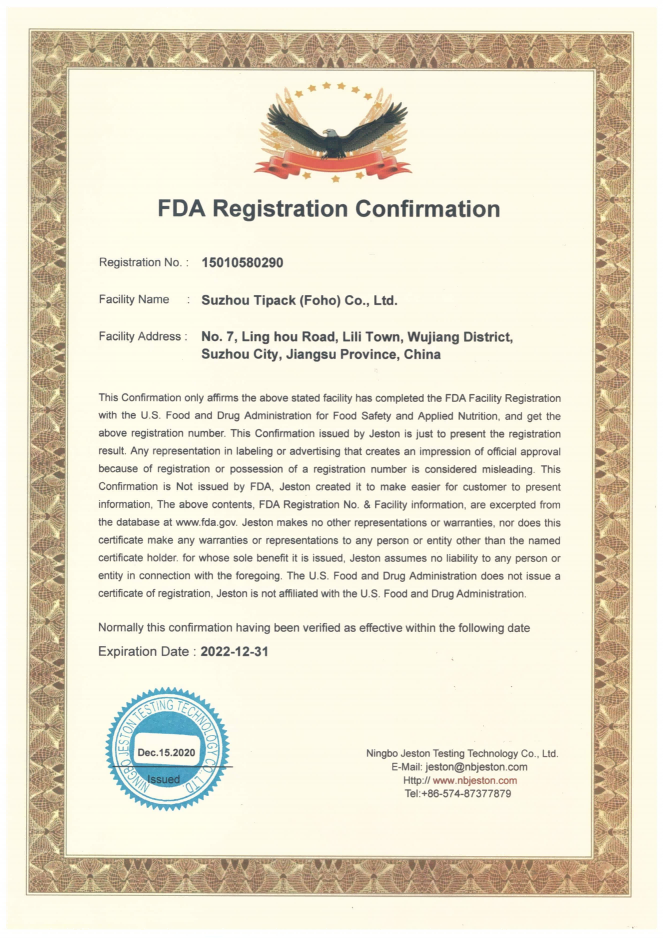

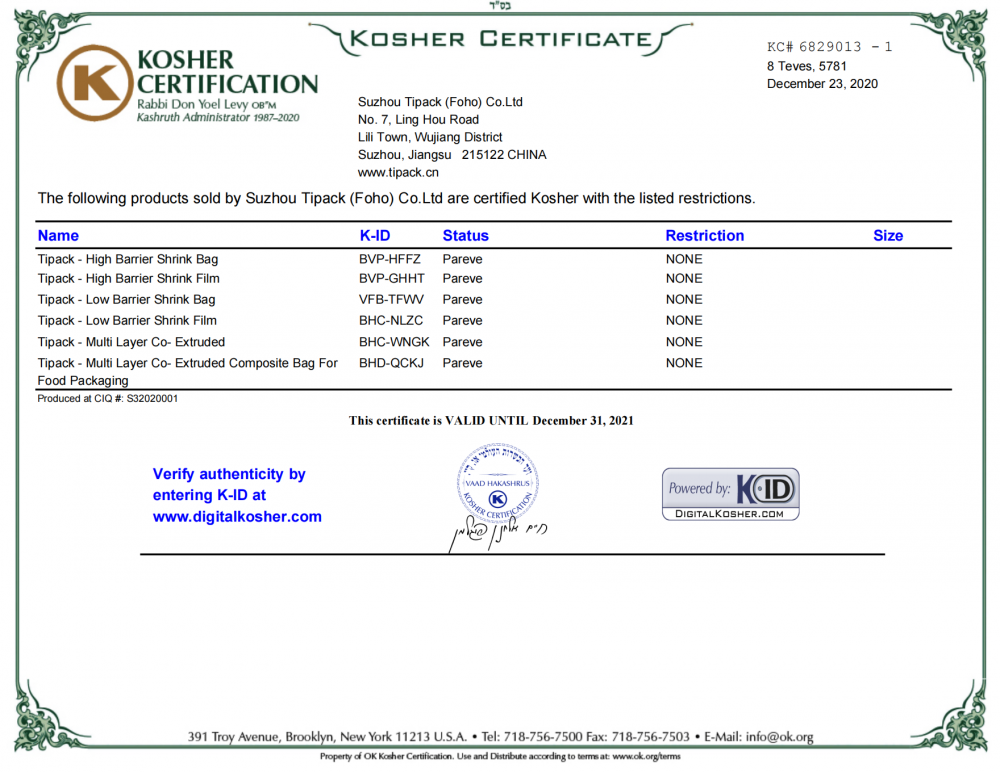

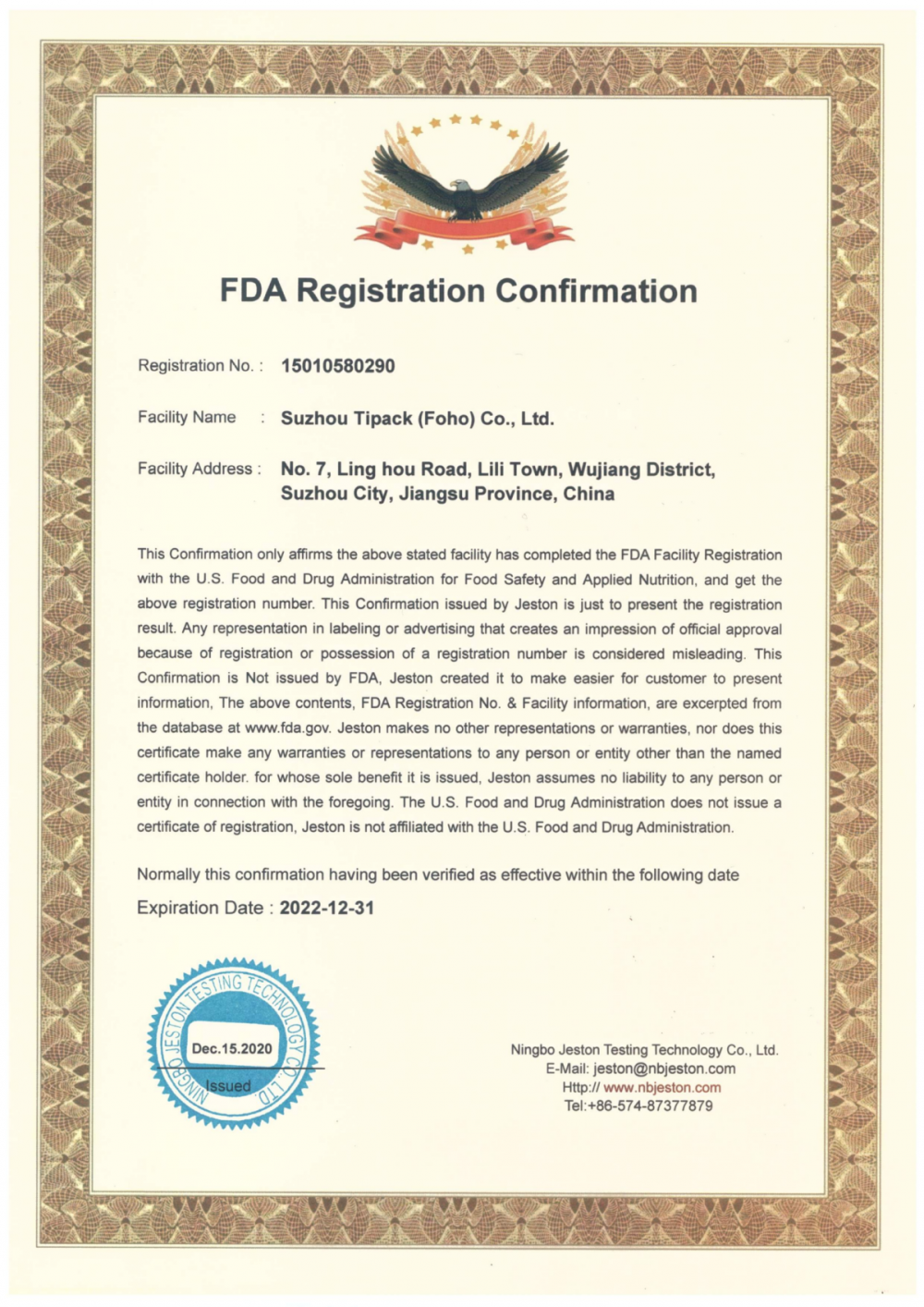

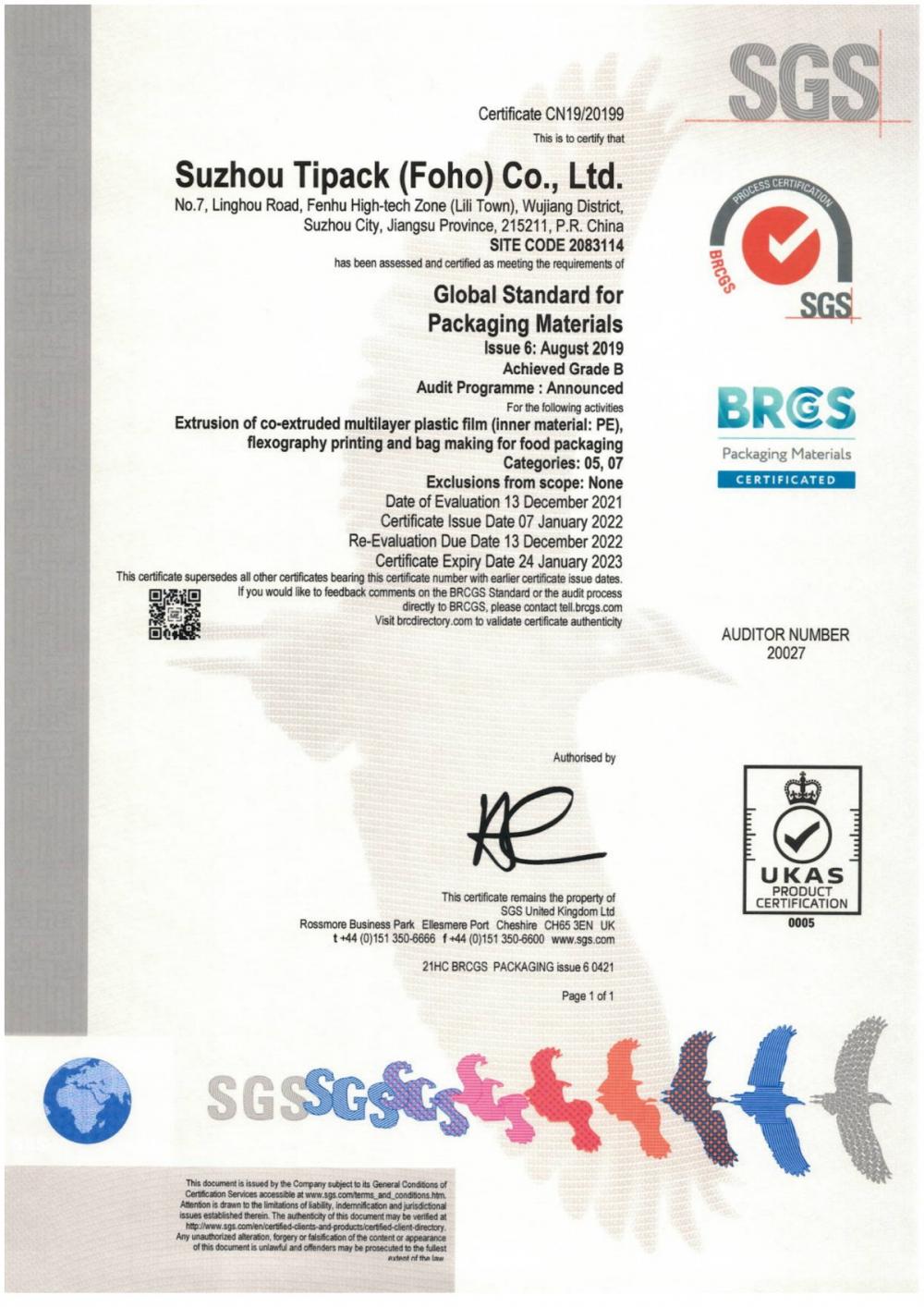

Since 2008, Tipack has over a decade of experience providing total packaging solutions to producers and sellers of livestock meat, poultry, seafood and dairy products worldwide. Tipack has passed HACCP, ISO22000 and FDA quality management system certification, and has also passed authoritative quality testing and certification such as Kosher, BRC, and SGS.

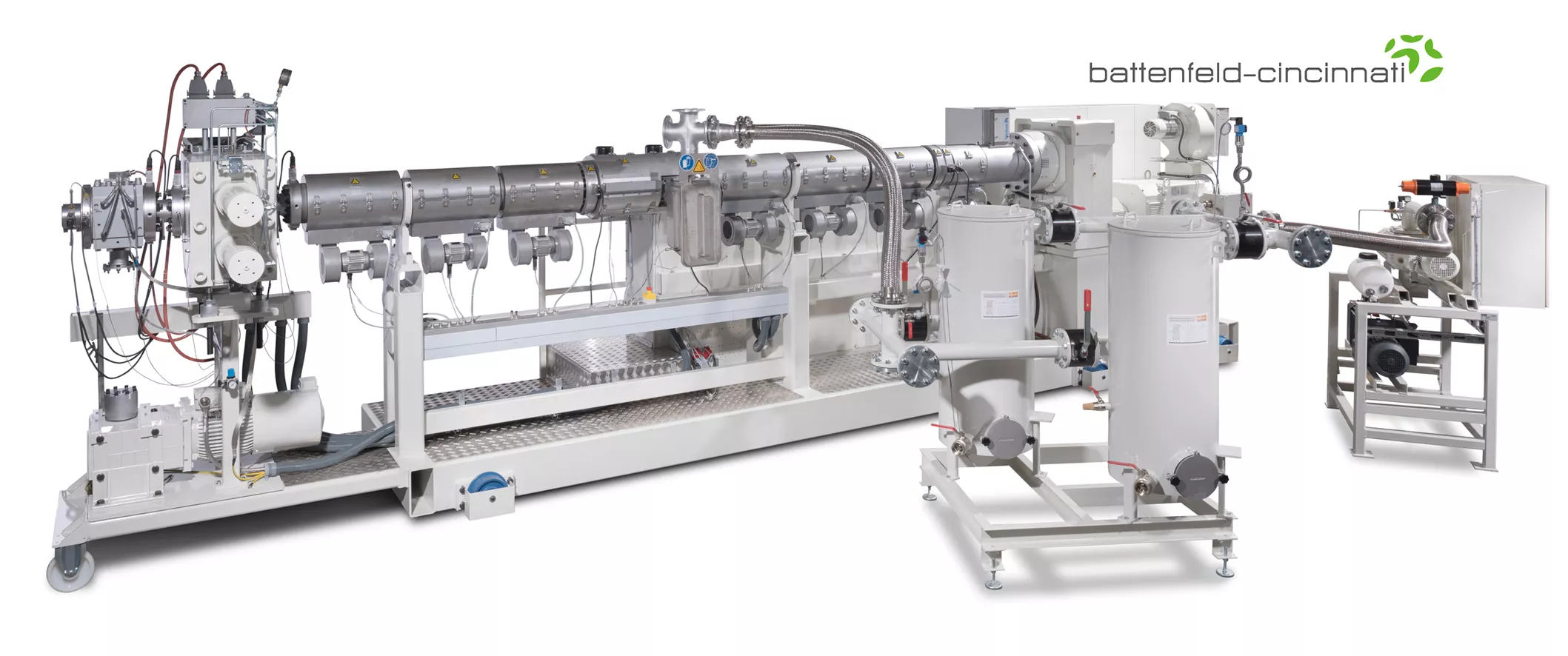

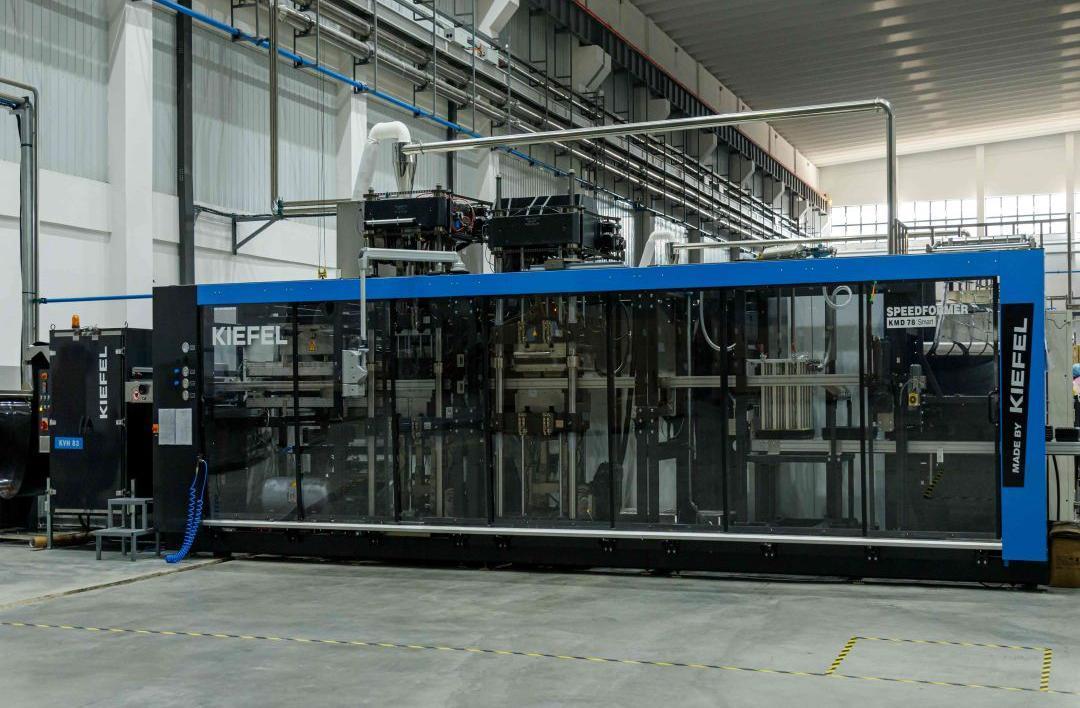

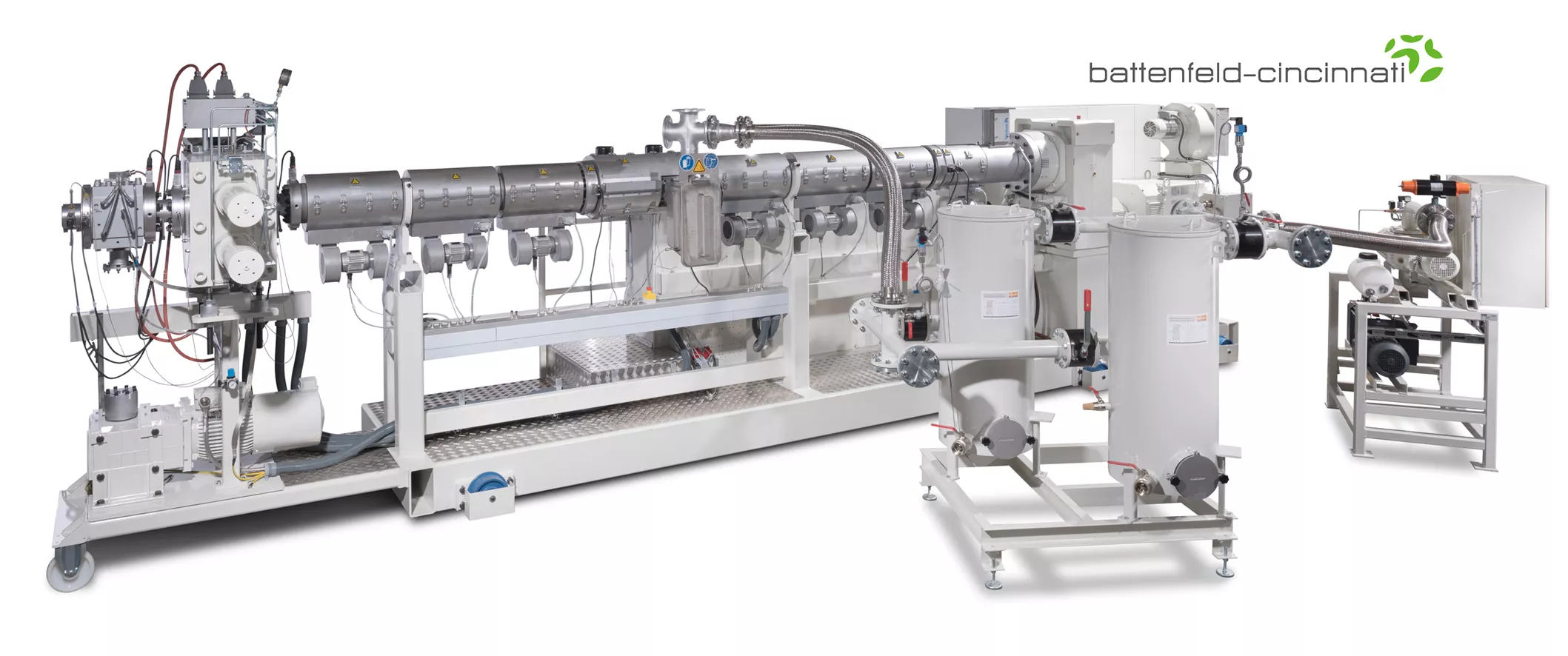

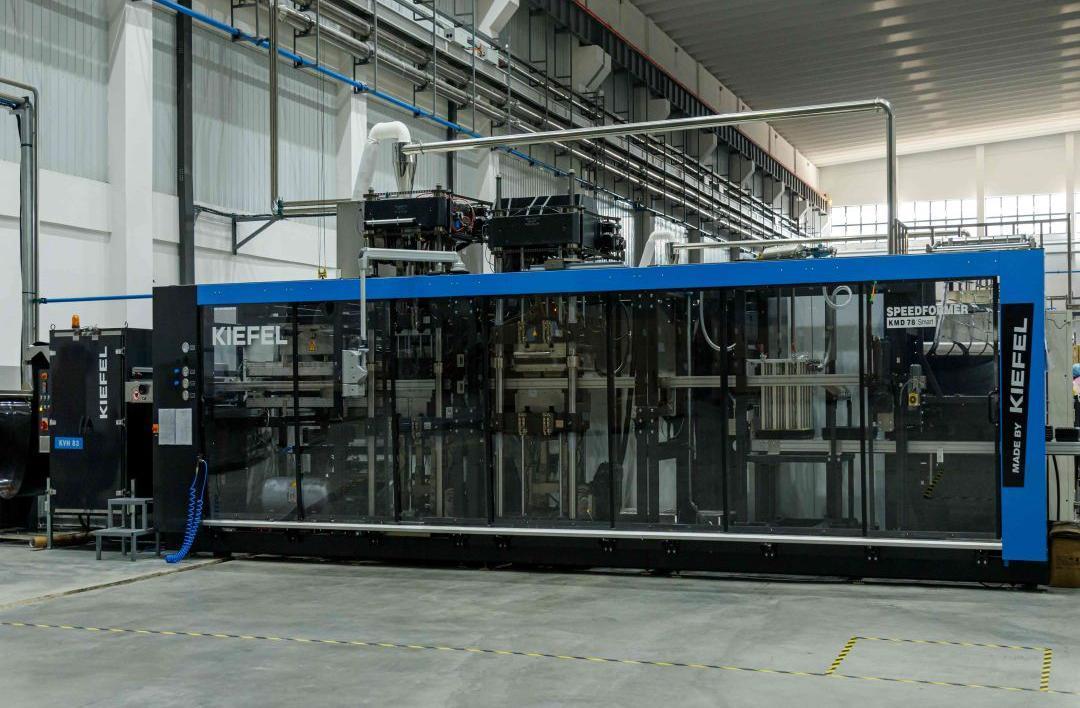

Tipack has many factories and production lines with a total area of more than 100,000 square meters, and adopts the most advanced production technology and process management system and quality tracking system. Provide customers with sample service, design service, ODM service, OEM service and other personalized customization. The production department of Tipack adopts the self-developed film blowing system, manufacturing equipment of German brands such as Battenfeld, iLLiG, KIEFEL and the most advanced satellite flexographic printing machine in Asia.

Tipack is the drafter of China's "Technical Specification for Meat Heat Shrinkable Packaging" and one of the contributors to the industry standard "Technical Requirements for EVOH High Barrier Composite Plastic Containers for Canned Foods". Tipack has grown into an internationally renowned technology-based enterprise with independent core technology, independent R&D and quality inspection systems.