Aluminum composite panel assembly machine production line

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Shanghai/Zhangjiagang or other port

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 10 Set/Sets per Year |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Ocean |

| Port: | Shanghai/Zhangjiagang or other port |

A2 B1 Multifunction Fireproof Aluminum Composite Panel

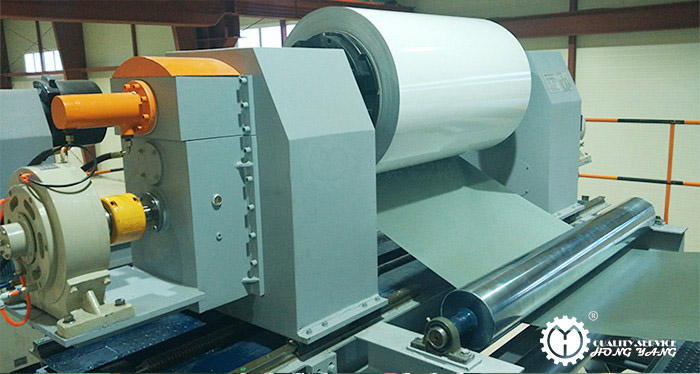

Hongyang Machinery developed the latest generation Aluminum composite panel production line for both Normal and A2 noncombustible composite panel. This new product can make the new beginner cutomer to invest less but can produce different kinds grade ACP.

If you want to know more HONGYANG MACHINERY service , pls send us inquiry without hesitate !

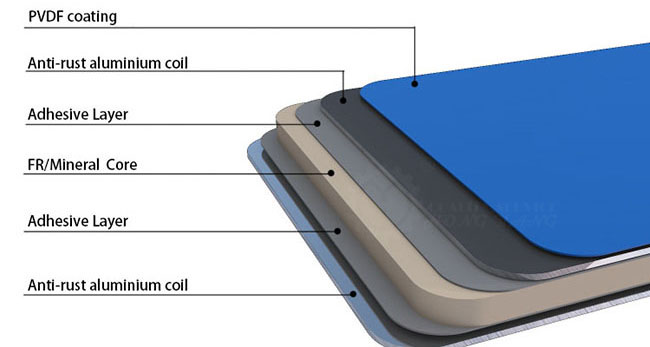

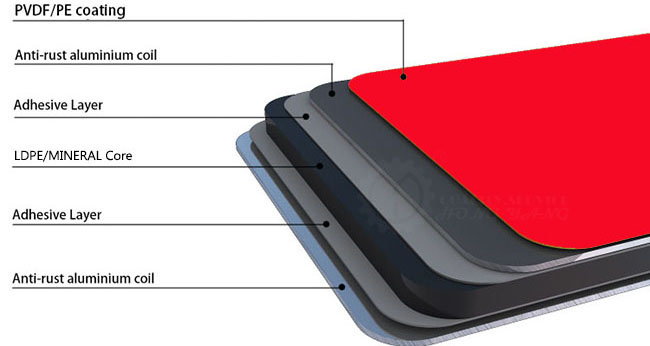

Structural Composition

The inevitability of A2 ACP for Facade

A2 B1 Aluminum Composite Panel Production Line

Stablely Unwinding System

Finish Panel Quality

Automatic Electrical Control System

Professional.

Machine Layout.

Sample Project.

HONGYANG MACHINERY | ||

Conventional packaging: inside is wrapped with PE film outside is wooden box. | ||

Delivery. | The normal delivery period is 90 days, depending on the place order time, the specific time is about 90 to 120 days. | |

Details. | We will make detail packing lists even one nut, also make very clear photo for each package. | |

Zhangjiagang Hongyang Petrochemical Machinery Co.,Ltd.

1 / Standardized workshop of total 10,000 square meters.

2 / The equipment will be well assembled and test before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechnical stability.

3 / Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

Hongyang Sales Manager Team and Engineer Team.

1 / Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

2 / The engineers are experienced. We can produce different product with different kinds of requirements and work out reasonable flow chart as per customers' requirements to save space.

Hongyang Machinery Cetificates and Patents.

2 / Verification Certificates of equipments: ISO9001:2015; CE Certificate , TUV

3 / National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Saso certificate of Saudi Arabia, etc.

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● The meaning of visiting supplier, because seeing is believing, Honyang Machinery with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

SEE HONGYANG MACHINERY HOW TO ENSURE THE QUALITY!

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will assembling all the machines and run parts testing for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF HONGYANG MACHINERY!

● After the commissioning, we will package the equipment by standard export package for shipment.

● We will arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

Related Keywords