Excellent performance water ring pelletizing line

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Jiangsu, China |

|---|---|

| Payment Type: | T/T,D/P,Western Union,L/C |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE, ISO |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

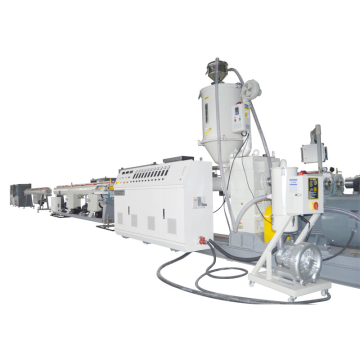

Excellent performance water ring pelletizing line

Process Flow

Among the water ring granulating line, polymer exiting the extruder passes die into the pelletizing chamber. In the chamber, the molten polymer flows through an annular die, which is equipped with a flexible blade at the die face. The blade cuts the molten polymer as it extruding from the die. After cutting, molten pellets are thrown into a ring of falling water in the cooling chamber. Pellets are cooled into solid state. The cooling chamber and the high water flow prevent the molten pellets from agglomerating during cooling. The water and pellet mixture is flushed to the de-watering unit, where excess water is removed from pellets. At last, the water recycles back to the cooling chamber. The final drying of pellets is done by centrifugal dryer.

Features of the produced pellets

Water ring granulating system produce rounded but flat pellets with the shape of similarly aspirin tablets. It is because of the specific cutting process.

As the polymer exits from the multiple holes, the rotating knives cut the polymer and throw outward into the water ring chamber. The water cools the pellets and transports them to vibration sieve filtration to check the quality of the pellets. Only the pellets with stipulated size can be transported to the centrifugal dryer for drying. According to the character of the polymer, the cooling process could be improved.

Advantages of the Lanbo machinery

As an experienced manufacture of plastic granulating line, we provide production validated product for customers, guarantee the performance of our equipment and offer considerable after-sale services to ensure the successful operating of your production line.

Our granulating equipment is listed based on the classification above. For example, string cutting granulating line, water ring granulating line and underwater granulating line. For customer searching easily, the equipment have been classified based on their applications, such as PVC granulating line, PET granulating line, single screw granulating line and conical twin screw granulating line.

For the customized granulating solution, equipment quotation and any unclear points around the equipment or production, we are glad at your service.

Related Keywords