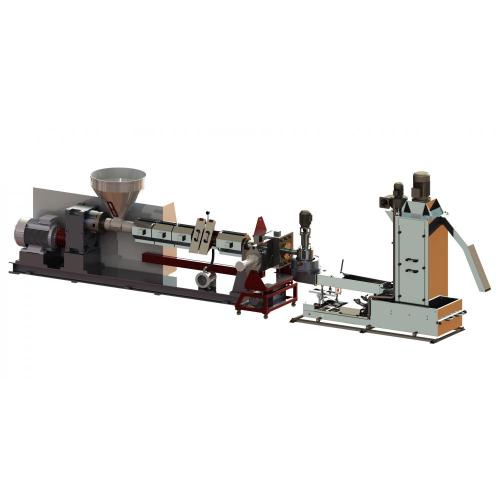

Water Ring Pelletizing (WRP) System

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Jiangsu, China |

|---|---|

| Payment Type: | T/T,D/P,Western Union,L/C |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE, ISO |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

Water Ring Pelletizing (WRP) System

Processing Description

In water ring pelletizers, as in under water pelletizing (UWP), the molten polymer flows through the multiple holes of the die plate. As the polymer emerges from the dia face. The cutting is accomplished by the rotating knives, which are assembled in the die plate. A contact between die plate and rotating cutting knives not only the polymer pelletizing but also the wearing. The die face is made of hardened metal, so the wear happens mainly on the knives. The contact will be applied by hydraulic pressure.

Characters of produced Pellets

WRPs produced pellets that are round but flat, are similar to aspirin tablets. It is due to the cutting process.

As the polymer exits from the multiple holes, the rotating knives cut the polymer and throw outward into the water ring chamber. The water cools the pellets and transports them to vibration sieve filtration to check the quality of the pellets. Only the pellets with good size quality can be transported to the drying process. According to the character of the polymer, the cooling process could be enhanced.

Features of the WRP processing

RP is most vulnerable among the three major pelletizing processes (Standrd Pelletizing, WRP and UWP) and has a great operation automation. By using push-button, the starting and stopping of the system can be controlled, and the rotation speed of knives adjusted. The UWP is significantly less sensitive to process parameter like melt temperature and pressure. For that reason, it is no risk of freeze-off.

Because the pellets are cut as molten polymer, thrown out and cooled with water, the to be processed materials should have high-melt-strength such as polyolefins and polystyrene. And the capacity is usually not so high as UWP processing. For that reason, the sticky material or high heat processing is not suitable for WRP.

Contact us

The customized WRP system should fit the pace of the whole prosecution line. We are looking forward to providing you our professional suggestions about the strand pelletizing system and the whole production solution. If you want a customized production solution or one copy product quotation, please feel free to contact us getting more detailed information.

Related Keywords