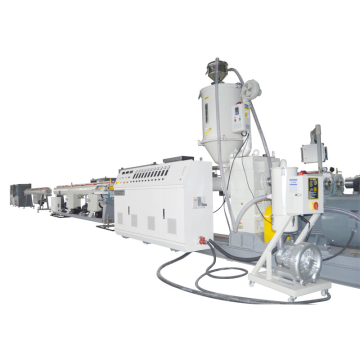

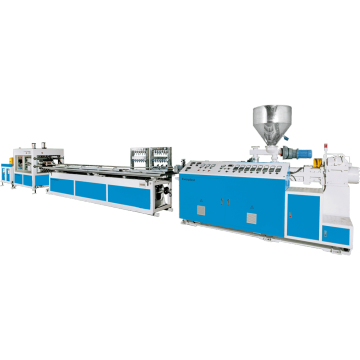

Lightweight Wall Panel Machinery Production line

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Jiangsu, China |

|---|---|

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

Lightweight Wall Panel Machinery Production line

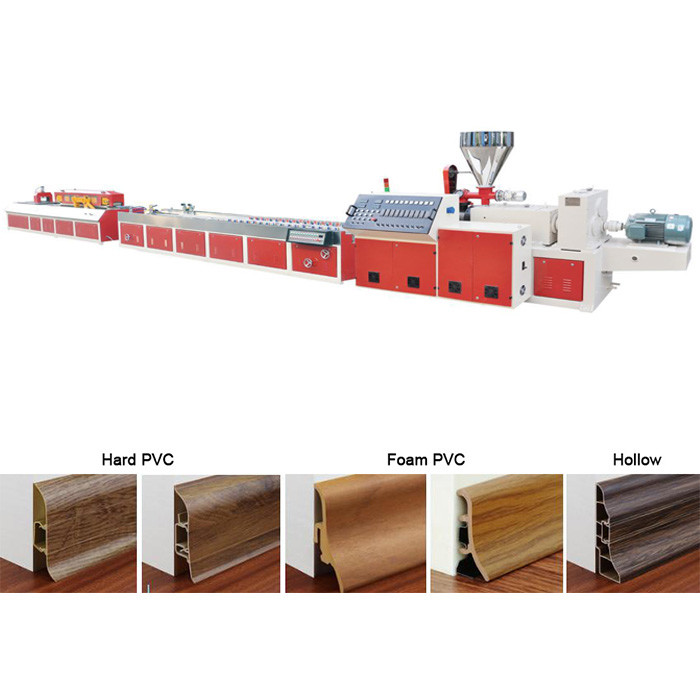

ADVANTAGES OF PVC PROFILE FOR WALL PANEL

1. Varies of colors and patterns. Showing authentic wood structure and artistic sense. Customized designs.

2. Wide using areas. For indoor wall decoration.

3. High intensity, resist erosion, anti aging. Fireproof, waterproof, environmental friendly.

4. Easy installing, cleaning and maintenance.

5. Long using life.

PERFORMANCE OF PVC WALL PANEL PRODUCTION LINE

PVC wall panel extrusion line mainly used for the production of PVC hollow panel like ceiling panel, wall panel, furniture panel, etc. The wall panel making machine consists of conical twin screw extruder, mold, vacuum calibration table, tractor, cutting machine, laminating machine, stamping machine and so on. PVC ceiling/wall panel production line has wide adjustment range, high temperature control precision and convenient and reliable operation.

THE COMPLETE EXTRUSION CONSISTS OF FOLLOWING ITEMS:

· Conical Twin Screw Extruder:

· It is used for melting and stirring plastic material. LANGBO adapts special screw and barrel type that provide perfect mixing and homogenous. We use special gear box for the Extruder which has axial bearings. Transfer the motor to the screw. For minimizing electricity consumption, we use the famous brand of driving motor of “SIEMENS” on our Extruder. Automation system designed with PLC and touch panel controller can be selected.

·

· Mould:

· Our mould designing gives ideal viscosity to melt material for profile producing. It gives profile or shape to plastic after processing. All faces the plastic in contact with is polish, so that frication losses minimized.

· Calibration Table:

· The shaped profile that come from mould is subjected to calibration and cooling processing on the calibration table. The designing of calibration table varies according to the type and characteristic of the profile. The area that contacts with water is made of stainless steel in order to prevent corrosion.

· Caterpillar Haul-off:

· The designing of caterpillar haul-off changes depending on the contact area that is related to the profile measurement. The inverter control is standard on all caterpillar haul-off. For this reason, as the speed can adjusted with respect to material output rate. The caterpillar haul-off is also capable of making measurement adjustment through speed control equipment.

· Saw cutter:

· In the speedy working condition, profile saw works with high efficiency in term of cutting frequency. As the saw table and clamps move synchronously. The saw cuts the profile in required length.

· During the cutting processing, swarf and dust appears, in order to prevent these in production area, there is a dust collection unit is integrated in saw cutter. This unit absorbs swarf, dust effectively and removes to storage.

· Tip-off unit:

· It operates on pneumatic cylinder.

The Table provides a general information for standard Product.

For Further customized technical assignment please contact us.

|

Model |

SJZ45 |

SJZ51 |

SJZ65 |

SJZ80 |

SJZ92 |

|

Screw diameter (mm) |

45/100 |

51/105 |

65/132 |

80/156 |

92/188 |

|

Screw rotation speed (r/min) |

4-45.5 |

1-30 |

1-34.7 |

1-36.9 |

1-32.9 |

|

The effective length of the screw (mm) |

1000 |

1050 |

1430 |

1800 |

2520 |

|

Main motor power (kW) |

15 |

22 |

37 |

55 |

90 |

|

Barrel heating power (kW) |

12 |

18 |

24 |

36 |

48 |

|

Capacity (kg/h) |

95 |

110 |

250 |

380 |

520 |

|

Central height (mm) |

1000 |

||||

|

Net Weight(kg) |

3000 |

3200 |

5000 |

6500 |

7500 |

Related Keywords