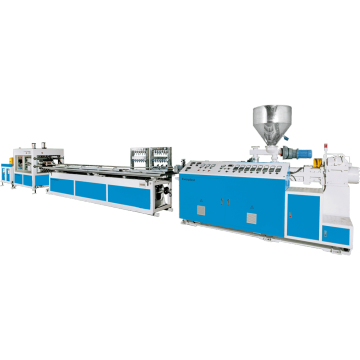

PVC Wall Panel Production Line

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P |

|---|---|

| Incoterm: | FOB,EXW,CIF |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

PVC Wall Panel Production Line

TECHNICAL DETAILS AROUND THE PRODUCTION LINE:

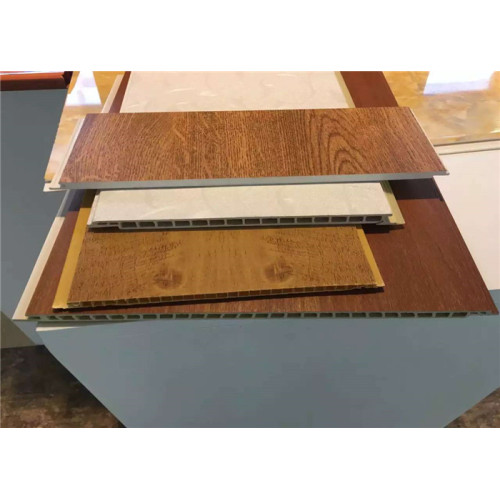

- PVC wall panel extrusion machine is a kind of special equipment for extruding PVC compound. With different kinds of molds and auxiliary machines, it can produced all sorts of PVC plastic, profile, plate material, sheet material, bar material and granulation.

- PVC extruder for PVC Ceiling Panel / Wall Panel has applied an oil cooling system. The barrel is cooled by a special wind cooling system.

- Ceiling Panel and Wall Panel extruder plant system have applied special computer control. According to customers requirements, most reasonable structure of conical twin-screw can be made so as to achieve the best plastic city performance and material quality

- Plastic Extruder machine for Wall panel is made by high precision special digital screw miller; extruding property can be highly harmonized. It has firstly introduced the advanced technique of producing the screw with variable pitch and depth so that the material can be more softly sheared and cut.

- The distribution box on Walling Panel making machine is specially designed, the pull force bearing is fully imported, and the drive life span can be prolonged. It can bear large extruding pressure.

- Plastic extrusion for PVC wall panel and ceiling panel electrical system has mainly applied imported parts, it has multiple alarm system, and there are few problems which can be easily eliminated. The cooling system has applied a special design, the heat emission area is enlarged, the cooling is rapid, and temperature control tolerance can be ± 1 degree.

EXTRUDER FEATURES:

We target to provide the optimal solutions for the customer’s special needs with the advantage of flexibility in material choices, high performance and long durability. As the heart of the production we optimized the extruder for a stable and energy-efficiency production.

SJZ Series Conical Twin Screw Extruder Machine - PVC wall panel extrusion making machine plant.

- Gearbox: adopting super quality gear box and reducer, with nice outline, stable running, low noise and long service time.

- Extruding barrel temperature controlling system: adopting cast aluminum heaters with stainless steel covers, wind cooling system, ensuring good features of cooling and heating, precision temperature controlling.

-

Screw and barrel: screw core installing with internal temperature controlling system, barrel equipped with vacuum degassing system, can get rid of the waste gas from the raw material which can guarantee super quality of the products.

-

Siemens Electrical Element: our machine choose high quality material for producing each details. SIEMENS elementsis well-know greatest quality, guarantee machine's operate.

SPECIFICATION:

The Table provides a general information for standard Product.

For Further customized technical assignment please contact us.

| Model | SJZ45 | SJZ51 | SJZ65 | SJZ80 | SJZ92 |

| Screw diameter (mm) | 45/100 | 51/105 | 65/132 | 80/156 | 92/188 |

| Screw rotation speed (r/min) | 4-45.5 | 1-30 | 1-34.7 | 1-36.9 | 1-32.9 |

| The effective length of the screw (mm) | 1000 | 1050 | 1430 | 1800 | 2520 |

| Main motor power (kW) | 15 | 22 | 37 | 55 | 90 |

| Barrel heating power (kW) | 12 | 18 | 24 | 36 | 48 |

| Capacity (kg/h) | 95 | 110 | 250 | 380 | 520 |

| Central height (mm) | 1000 | ||||

| Net Weight(kg) | 3000 | 3200 | 5000 | 6500 | 7500 |

Related Keywords