WPC Products produced by WPC Extrusion Line

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Jiangsu |

|---|---|

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

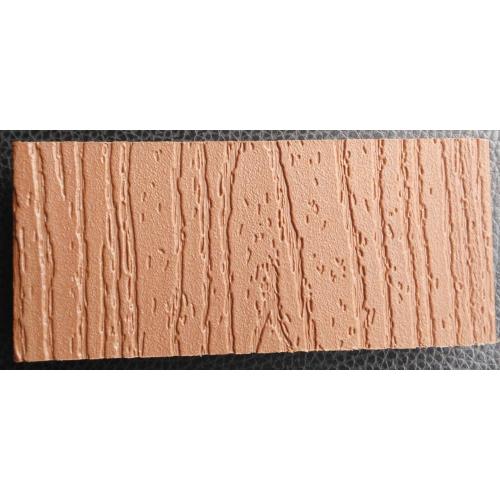

WPC Products with produced by WPC Extrusion Line

CHARACTERS AND MARKET OF WPC MATERIAL

The WPC Product is seen as a ideal combination of plastic and

nature. It combines the advantages of plastics

with nature fiber material like wood. The WPC Products are more pliable than conventional

solid wood boards and more environmentally-friendly than purely plastic

products.

In North America, Europe and Asia the Market of WPC Products is already in a large volume.

APPLICATIONS OF WPC PRODUCTS

According to the application situations, the end product can be distinguished as Outdoors and Indoors Products. The application examples and their advantages are listed below.

WPC Products for Outdoors application

terrace decking, railings and borders

fences

wall cladding

noise barriers

privacy screen panels

hut systems/temporary shelters

Advantages

• Splinter-free, slow fading or colorfast

• Flexible design and surface structure

• Resistant to moisture and organic attack

• Low thermal expansion and weather resistance

WPC Products for Indoors application:

Doors and door frames

furniture

skirting boards

window sills

decorative applications/trimmings

Advantages

High acceptance in hot climates with high humidity

Material:

To avoid fiber degradation or burning the processing temperature should not exceed 200ºC. So the melt temperature of the polymer is limited. PP, PE, PVC are commonly used in NFC/WPC formulation. Depending on the availability and quality/purity the virgin or recycled polymers can be used.Processing Concept:

The second steps processing concept is commonly used. With the 2 Steps processing the raw material will be first compounded into interpediate product like agglomerate, powder, granulate and then the compounds will be formed by extruder.

the processing flow runs below:

raw material – Compounding (heating-cooling mixing, twin screw extruder) – interpediate product (agglomerate, powder or granulate) – Form Extrusion (plasticizing, homogenizing, pressure build-up)- Calibrating – Cooling- -Cutting -Surface treatment

Advantage:

stable production, less situation sensitive, high output than 1 Step process

Disadvantage:

more equipment investigation (compounding system necessary), for flakes granulates the working environment is poor(dusty), more energy consumption

LANGBO, THE EXPERIENCED WPC PROFILE PRODUCTION LINE MANUFACTURE

Langbo Machinery has been focusing on the NFC Extrusion for our 15 years. The Extruder series are specific designed for production of WPC or NFC. Based on our long term cooperation with partners at the different role of WPC Producing, we are able to give the comprehensive production solution and technical support.

Related Keywords