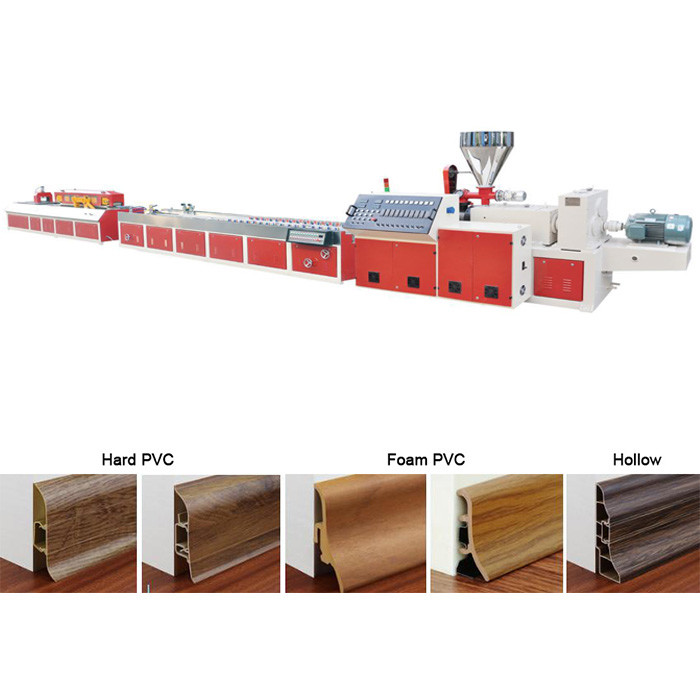

WPC Profile Production Line

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Jiangsu, China |

|---|---|

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,EXW,CIF,CFR |

| Certificate: | CE |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

WPC Profile Production Line

PRODUCTION LINE COMPONENTS AND FEATURES:

PVC/PE/PP and wood composite profile extrusion lines are applied for manufacturing WPC Products such as architecture, decoration in-outside room, transportation stockade, chair and table outside room, etc..

The complete WPC profile production line consists of following items:

- Conical twin screw extruder

- Die head and vacuum calibrating die

- Vacuum table

- Haul-offs

- Cutter

- Tipping chute

- Surface treatment equipment, such as film lamination, printing and stamping, etc..

Production Process:

Raw material +wood power+ additive ~ mixing ~granulating ~ conical twin-screw extruder ~ profile extrusion mould~ cool molding die ~ vacuum calibration support ~ belt haul-off ~cutter ~ rack ~ finished product inspecting & packing

The Table provides only a general information for standard Product.

For Further customized technical assignment please contact us.

| Model | SJZ45 | SJZ51 | SJZ65 | SJZ80 | SJZ92 |

| Screw diameter (mm) | 45/100 | 51/105 | 65/132 | 80/156 | 92/188 |

| Screw rotation speed (r/min) | 4-45.5 | 1-30 | 1-34.7 | 1-36.9 | 1-32.9 |

| The effective length of the screw (mm) | 1000 | 1050 | 1430 | 1800 | 2520 |

| Main motor power (kW) | 15 | 22 | 37 | 55 | 90 |

| Barrel heating power (kW) | 12 | 18 | 24 | 36 | 48 |

| Capacity (kg/h) | 95 | 110 | 250 | 380 | 520 |

| Central height (mm) | 1000 | ||||

| Net Weight(kg) | 3000 | 3200 | 5000 | 6500 | 7500 |

Related Keywords