Indoor WPC Floor Production

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China |

|---|---|

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,EXW,CIF |

| Certificate: | CE |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

Product Description

Product Description

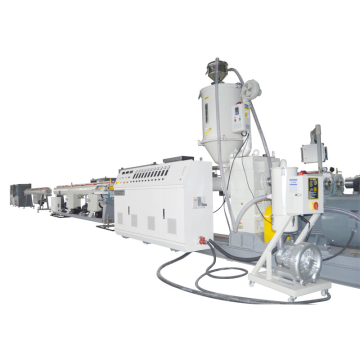

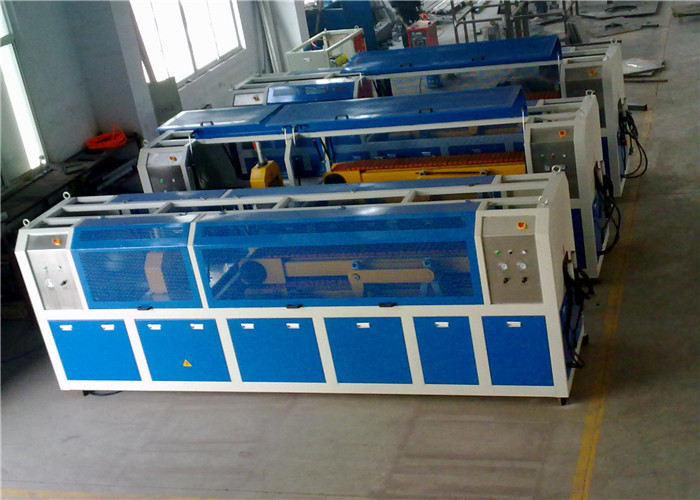

Indoor WPC Floor Production Line

ADVANTAGES OF WPC COMPOSITES :

WPC (Wood Plastic Composites) is one of the natural fiber composites.

Because of its durability, natural fiber composites are increasingly replacing pure natural products in many application areas, for example, decking products, fence components or screening walls. Langbo Machinery supplies complete system solutions for the applications.

PVC is an extremely versatile material that is generally available as a dry (powder) blend. Prior to processing in the extruder, additives are blended into the virgin PVC in a heating/cooling mixing unit. PVC compounds are sensitive to shearing and high temperatures and are therefore gently processed on either parallel or conical twin screw extruders, depending on throughput requirements

Conical twin screw extruder is widely used to process natural fiber-rein-forced plastics such as WPC (wood plastic composites). With an optimized design and logic combination of core components our extrusion line has other benefits such as stable material feeding, gentle, non-destructive processing and highly stable screw pressure for the production. So that the homogeneous melt wit optimum temperature will be extruded.

STRUCTURE OVERVIEW OF PRODUCTION LINE

- Extruder (single screw extruder, twin screw extruder, Co-extruder)

- Tooling

- Calibrating table

- Haul-off

- Cutting unit

- Tip table

PRODUCTION PROCESS:

Raw material +wood power+ additive ~ mixing ~granulating ~ conical twin-screw extruder ~ profile extrusion mould~ cool molding die ~ vacuum calibration support ~ belt haul-off ~cutter ~ rack ~ finished product inspecting & packing

SPECIFICATION:

The Table provides a general information for standard Product.

For Further customized technical assignment please contact us.

| Model | SJZ45 | SJZ51 | SJZ65 | SJZ80 | SJZ92 |

| Screw diameter (mm) | 45/100 | 51/105 | 65/132 | 80/156 | 92/188 |

| Screw rotation speed (r/min) | 4-45.5 | 1-30 | 1-34.7 | 1-36.9 | 1-32.9 |

| The effective length of the screw (mm) | 1000 | 1050 | 1430 | 1800 | 2520 |

| Main motor power (kW) | 15 | 22 | 37 | 55 | 90 |

| Barrel heating power (kW) | 12 | 18 | 24 | 36 | 48 |

| Capacity (kg/h) | 95 | 110 | 250 | 380 | 520 |

| Central height (mm) | 1000 | ||||

| Net Weight(kg) | 3000 | 3200 | 5000 | 6500 | 7500 |

Related Keywords

Related Keywords