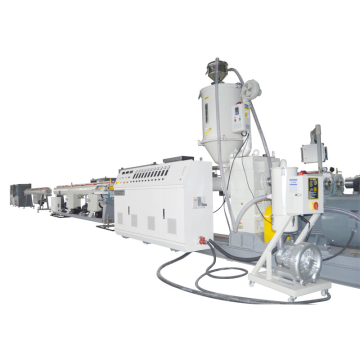

Plastic Strand pelletizing Line

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | JIANGSU, CHINA |

|---|---|

| Payment Type: | T/T,D/P,Western Union,L/C |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE&ISO |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

Plastic Strand Pelletizing Line

INTRODUCTION:

The processing granulation is usually used in plastic compounding and recycling. Concerning the plastic compounding, it means that the mixing of two or more components in an extruder produce a new product. During compounding, the virgin resins will be shaped with certain desired character by adding ingredients. And the plastic with new character will be extruded and granulated into pellets for storage and further application. As for the plastic granulating line, the processed post-industry and post-customer plastic will be melted, extruded and granulated into pellets, which are convenient for storage and further application. In general, the crushed or shredder plastic flakes which have been washed and cleaned have bad feeding efficiency for extruding, so the plastic granulating line for recycling is necessary.

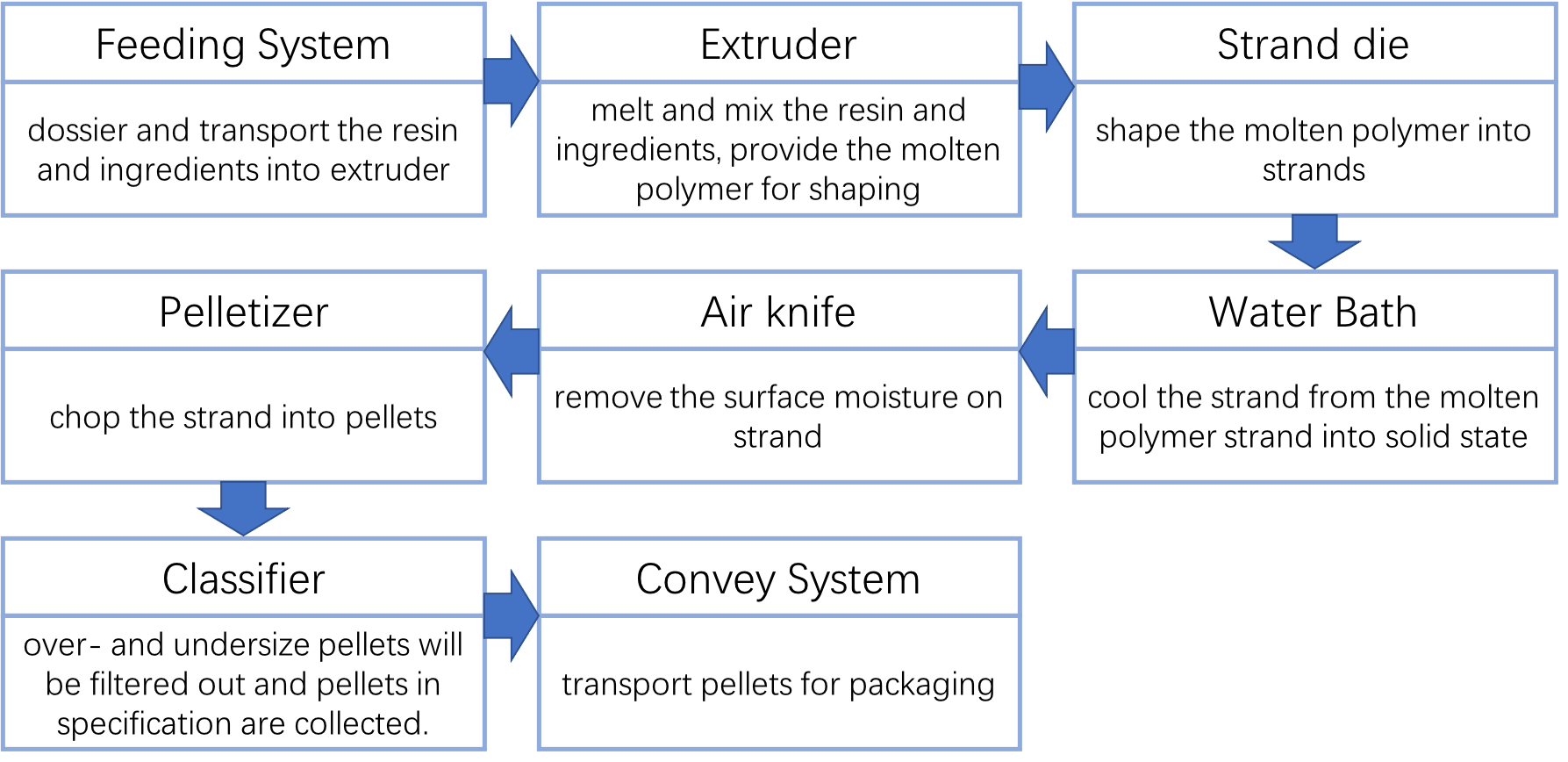

PROCESS DESCRIPTION:

The strand cutting pelletizing belongs to cold cutting granulation. It means that the polymer is extruded from the die head as strands and cut by pelletizer when the strands are cold into solid state. The strand cutting pelletizing can be applied for almost of the polymer granulating. Because of its pelletizing concept, the strand cutting granulating line has several advantages such as, low investment, easy operation and universal application.

STRUCTURE OF GRANULATING LINE:

The strand cutting pelletizing line has a relative stable structure. According to the individual application, each component may have different importance for the whole pelletizing line. This needs a further discussion around the customized structure solution. The basic structure and their function of the whole line are listed as following.

Feed system: dossiers and feeds the resin and ingredients into the extruder for mixing and melting.

Extruder: mixes and melts all the materials, which have been fed into the extruder.

Strand die: shapes the molten polymer into strand.

Water bath: cools down the extruded strands into solid state.

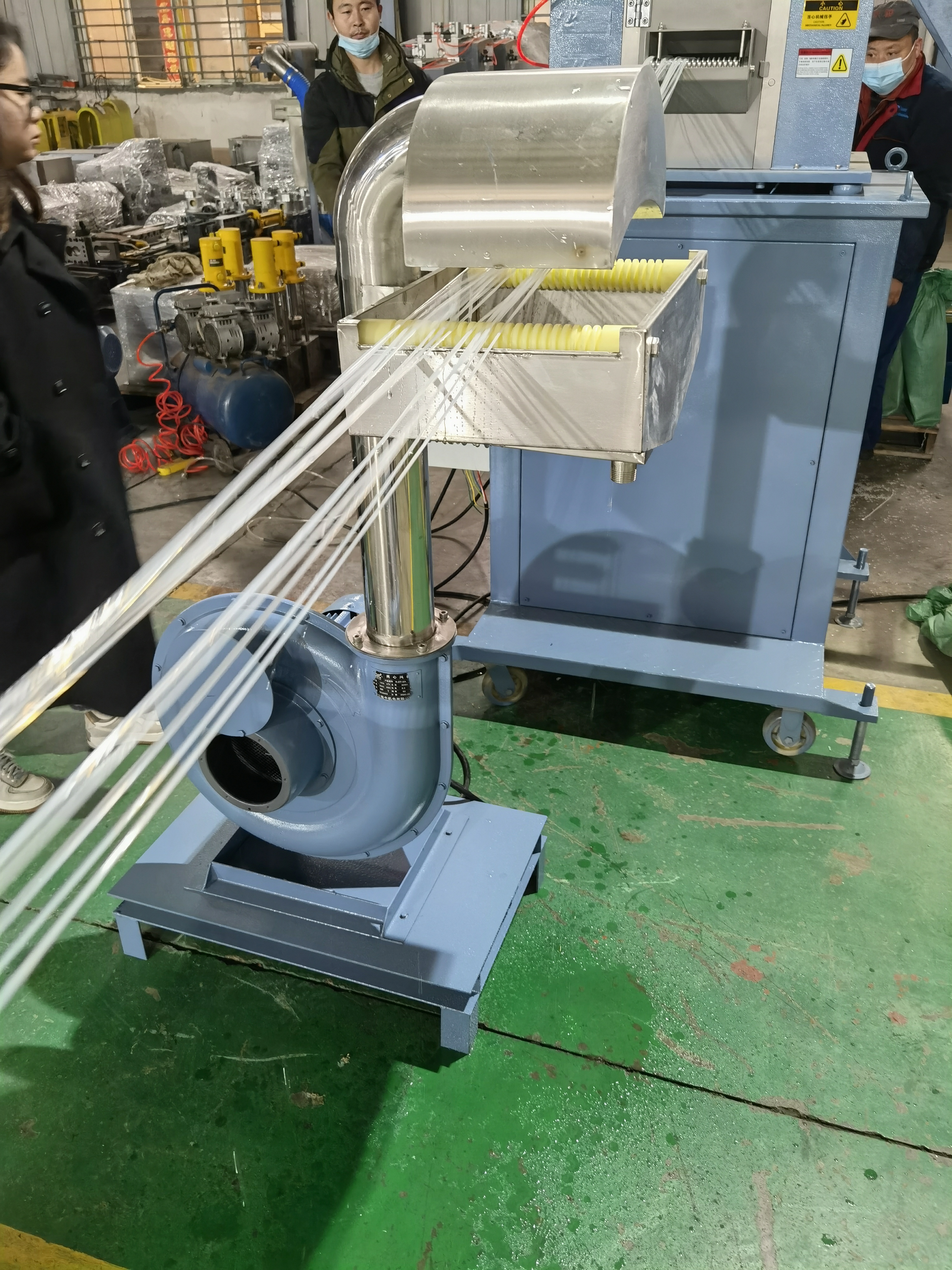

Air knife/ Air stripper: removes the moisture on strand surface.

Pelletizer: chops the strand to defined length.

Classifier: filters out the over-and under-sized pellets and collects the pellets, which fit the pellets specification.

Conveys system: transports the first quality pellets for packaging.

Related Keywords