Strand Cutting Equipment For Granulating

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | JIANGSU, CHINA |

|---|---|

| Payment Type: | T/T,D/P,Western Union,L/C |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE/ISO |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

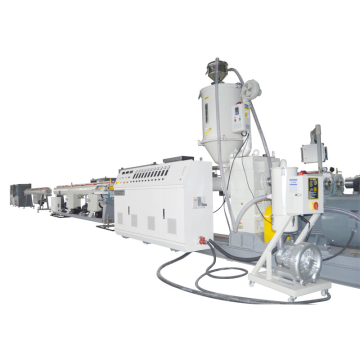

Strand Cutting Equipment For Granulating

INTRODUCTION:

The processing granulation is usually used in plastic compounding and recycling. Concerning the plastic compounding, it means that the mixing of two or more components in an extruder produce a new product. During compounding, the virgin resins will be shaped with certain desired character by adding ingredients. And the plastic with new character will be extruded and granulated into pellets for storage and further application. As for the plastic granulating line, the processed post-industry and post-customer plastic will be melted, extruded and granulated into pellets, which are convenient for storage and further application. In general, the crushed or shredder plastic flakes which have been washed and cleaned have bad feeding efficiency for extruding, so the plastic granulating line for recycling is necessary.

ADVANTAGES AND DISADVANTAGES:

Totally understanding the strand pelletizing process is conducive to figuring out whether the process fits the production condition or not.

As a universal granulating method, the strand pelletizing has following advantages:

• low equipment cost

• easy maintenance

• suitable for most of the materials

Disadvantages are listed in comparison with other pelletizing methods such as water ring or under water pelletizing :

• Relatively low automation grad

• high energy consumption

• more human resource needed

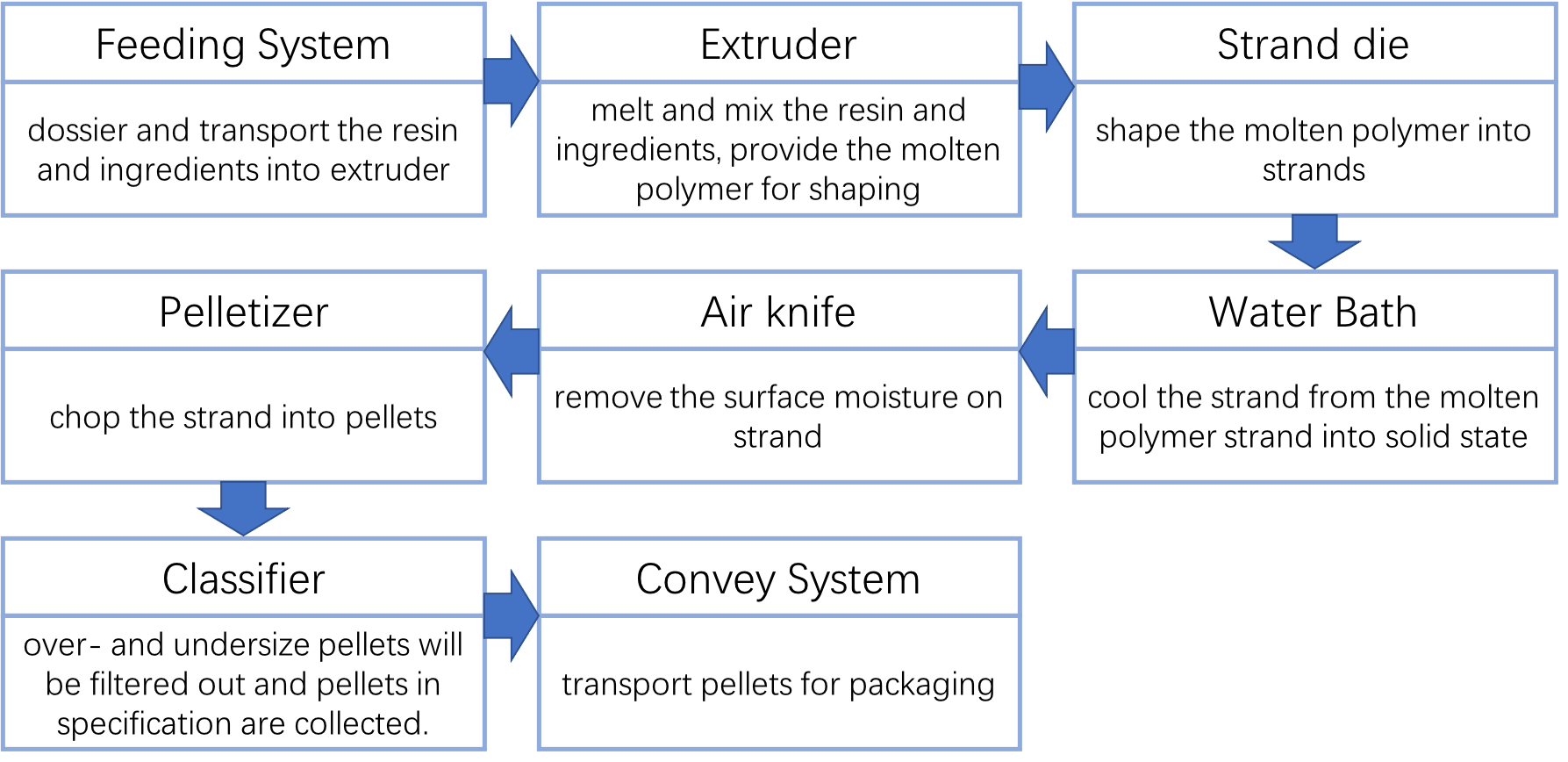

PROCESSING FLOW:

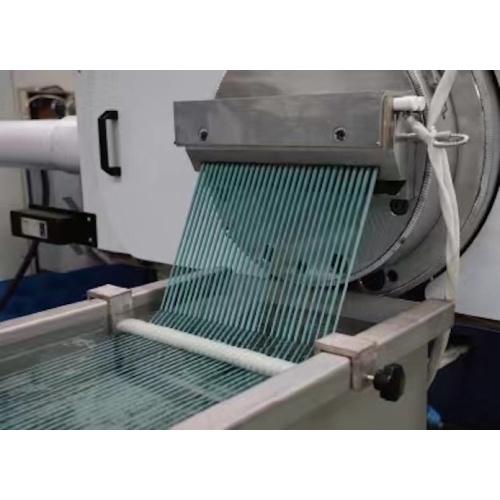

The strand cutting granulating process is one of the most common application for granulating. It is widely used for several kinds of material. The basic pelletizing process goes through the following path:

Related Keywords