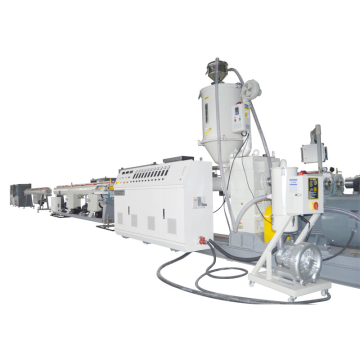

Single Screw Extruder Pelletizing for Plastic recycling

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Jiangsu, China |

|---|---|

| Payment Type: | T/T,D/P,Western Union,L/C |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

Single Screw Extruder Pelletizing for Plastic recycling

Application of Extrusion & Pelletizing System

According to customers' different production's condition combined with our almost 20 years' experience, we can always find out the best customized solution.

The most two important parts for pelletizing are extrusion system and pelletizing system. For extrusion there are some different kind of concept available. Like Single Stage or Double Stage single screw extruder or co-rotating parallel twin screw extruder. The application is always based on the production's requirement.

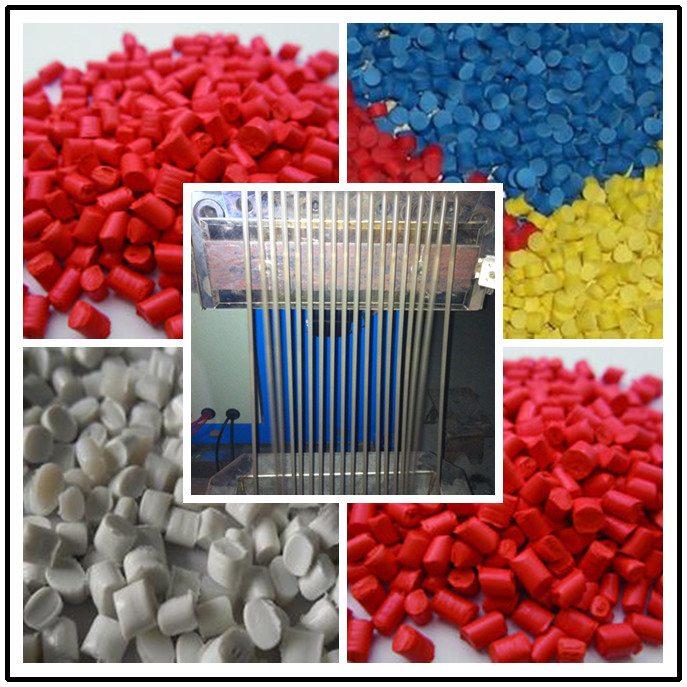

According to different material and processing, the pelletizing concept are also to be defined, we have water cooling strips (noddle) cutter method, water circu cooling cutting method, air cool hot cutting method , and others. when we offer you the machine , we will make the proposal according to your materials and your capacity need. the followng is some introduction of the machines.

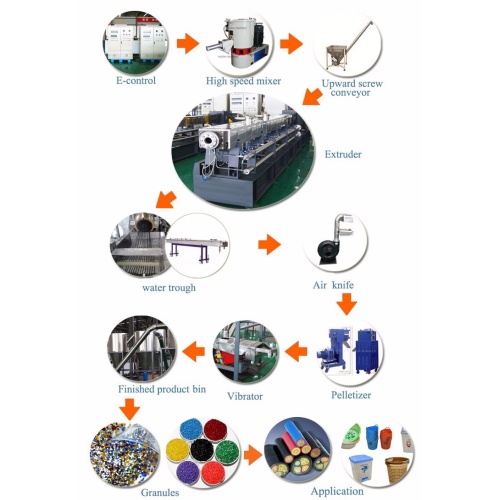

Strand Pelletizing Process description

In strand pelletizing, polymer is cut into pellets after it has cooled and solidified. The Molten polymer flows into a strand die which looks like a sheet die, and the material exits the die through multiple holes. Each hole shapes the material into polymer strand. The strands will be firstly cooled in water bath or trough, then dried by a de-watering unit or air knife, finally are fed into a strand pelletizer, where they are cut into pellets. This pelletizing concept can also be called as "dry cut" the strand will be pelletized after de-watering.

Feature of the Product

According to the pelletizing process, the pellets are cylindrical form. By "dry cut" the the flat end surface of the pellet can stick together and cause bridging.

Features of our Equipment:

1. High strength and elastic coefficient, high impact strength and wide temperature range;

2. High transparency and free dyeing;

3. Low shrinkage and good size stability;

4. Poor fatigue resistance;

5. Good weather resistance;

6. Excellent electrical characteristics;

7. Odorless and odorless are harmless to human health.

8. Machine design lower consumption and noise , easy and safe operation .

9. ABB, RKC,OMRON,SIEMENS brand

10. 1year warranty time

Contact us

The customized extrusin and strands pelletizing system should fit the pace of the whole recycling line. We are looking for providing you our professional suggestions around the strand pelletizing system even around the whole production solution.

Related Keywords