Co-Rotating Parallel Twin Screw Extruder

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Jiangsu, China |

|---|---|

| Payment Type: | T/T,D/P,Western Union,L/C |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

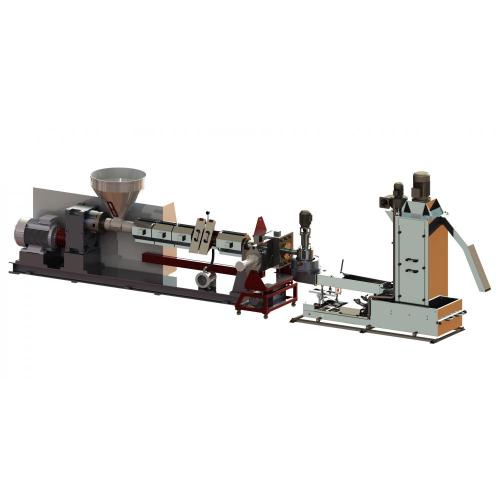

Co-Rotating Parallel Twin Screw Extruder

parallel screw plant application:

parallel twin screw extruder is widely used in various thermoplastic plastic filling ,compouding ,improving, modification, exhausting and vaporizing, stable coloring and even granulating , it is ideal equipment for high molecule chemistry line such as resin plant and plastic-making plant.

Components of Pelletizing Line

1. Feeding system

2. Twin screw extruder

Parallel co-rotating twin screw extruder

3. Auxiliary unit

Water cooling tank

Strand pelletizer

Technical parameter of PET plastic extruder pelletizing line (normal)

1. Feeding system

2. Twin screw extruder

3. Pelletizing system and auxiliaries

Frequency conversion speed adjuster

design for barrel and screw

Barrel electrical heating

Barrel water cooling

Electrical equipment

Vacuum system

parallel screw plant advantages:

1. Inverted rotation double-screw stem makes the material flow in shape. This can meet the thchnique demands of tranport, compression, mixture and refining, exhaust, plasticzing of the material.

2. The special oil heating system in the core of the screw stem can ensure the relative stability of the product quality.

3. Different models of screw stems of the machine are designed to match the relevant auxiliary machine to produce all kinds of pipe material, shaped material, grains and others.

4. The machine has advantages of advanced design, compact structure, excellent characteristics, beautiful appearance, steady operation, low energy consumprion, high output and long use life.

Specification:

We provide also the customized production line, please contact us and get a customized suggestion for your production plan.

Related Keywords