PVC Pipe Extrusion Machine Production Line

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | JIANGSU, CHINA |

|---|---|

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CIF,EXW,CFR |

| Certificate: | CE |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

PVC Pipe Extrusion Machine Production Line

THE ADVANTAGES OF PVC PIPE APPLICATIONS

These days the PVC pipes are broadly utilized. Contrasted and customary metal line, are as followed.

Erosion Resistant

With self-smothering and fire resistant;

Amazing in enemy of maturing character

The heaviness of PVC pipe is light, simple to erupting, holding, bowing, welding.

Establishment responsibility and Processing cost are lower than metal line

Great electrical properties of opposition

Reused and Environment-accommodating.

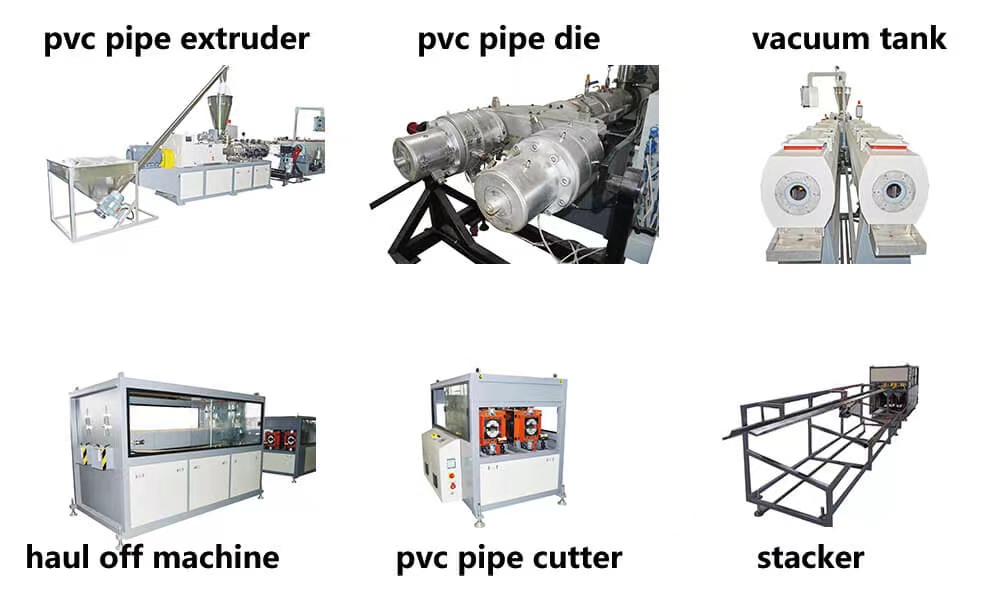

COMPONENTS INTRODUCTION

Conical Twin Screw Extruder

PVC compounds are delicate to shearing and high temperatures. Subsequently, we ought to tenderly handle on one or the other equal or tapered twin screw extruders, contingent upon the throughput prerequisites and line aspects. As the expert gear, the Conical twin screw extruder can deal with not just PVC compounds, the combination of PVC and wood/composite yet in addition mixtures of PP/PE and wood powder.

Mould

The line structure is formed by shape with different natural substances. The exceptional planning of our form gives ideal thickness of material dissolving, which impacts the line molding and expulsion energy. All countenances in touch with material are cleaned, hence, the expulsion rubbing can be limited.

Vaccum Calibration Tank and Cooling Tank

Through the Vacuum Calibration Tank, the line shape will be characterized. Other than that the surface nature of lines is impacted by this step. LANGBO Vacuum Calibration Tanks are fabricated with treated steel. The showering spouts are intended for most extreme cooling execution. The Cooling water sprinkles on the hot plastic line surface. Joined with the forming of the shape, the surface nature of lines will be characterized.

The tension on our vacuum tank can be changed, so vacuum strain can be fixed by the line prerequisites. We seal gasket for each cover on the vacuum tank. This stops vacuum spillage and limits energy utilization. We embraced the modern cycle innovation to ensure the nature of our items.

Calibration Unit

We have an extensive variety of drag away units which can give clients to the ideal arrangement with the width scope of 16 to 800 mm.

Caterpillar and Belt Haul-off units can be embraced as per the creation conditions.

Drag away speed can be associated with the expulsion speed, so the wall thickness are more even.

The Belt Haul-off unit is typically utilized for little line and fast expulsion. It is liberated from vibration and guarantee the superb control even at rapid. The Caterpillar can take the large lines without any problem. The Claws' surface is covering with froth PU which can forestall the slip among lines and hooks. The speed setting of belts and caterpillar can be changed by inverter. Hence, man can work on the control board without any problem.

Cutter

A shaper with elite execution can guarantee similar length of the cut lines. So the great encoder and exact shaper unit are required. Comparable like Haul off unit, the shaper has two plan ideas: saw shaper and planet saw shaper. It relies upon the breadth of cutting lines.

Control framework

The Control framework incorporates the entire tasks related regulator and agent, for example, PLC module, HMI board (Human Machine Interface), thermometer, connector, etc. The Elements with excellent is huge for a steady and exact creation.

Discretionary unit

For pipe creation, there are a few useful units like laser, ink printer, pipe stacker and attachment shaping machine.

With Printer the Pipe Manufacturer can compose the creation data on the Pipes.

Stacker can be utilized to gather the lines in the wake of cutting.

Attachment framing machine can shape one finish of the line into a greater measurement, with the goal that the two lines can interface start to finish.

SPECIFICATIONS

Creation Capacity has a cozy relationship with screw size and engine power. The accompanying table give you a generally characterization of our line creation arrangement.

For modified arrangement and subtleties, please go ahead and reach us.

| Model. | SJSZ45/90 | SJSZ51/105 | SJSZ55/110 | SJSZ65/132 | SJSZ80/156 | SJSZ92/188 |

| Transmission power(kw) | 15. | 18.5 | 22 | 37 | 55 | 110 |

| Screw diameter(mm) | Φ45/Φ90 | Φ51/Φ105 | Φ55/Φ110 | Φ65/Φ132 | Φ80/Φ156 | Φ92/Φ188 |

| Screw quantity | 2. | 2 | 2 | 2 | 2 | 2 |

| Rotation speed(r/min) | 45 | 40 | 38 | 38 | 37 | 36 |

| Screw Torque Nm | 3148 | 6000 | 7000 | 10000 | 14000 | 32000 |

| Extrusion Capacity(kg/h) | 70 | 100 | 150 | 250 | 400 | 750 |

| Center height(mm) | 1000 | 1000 | 1000 | 1000 | 1100 | 1200 |

| Lx W x H(mm) |

3360x1290 x2000 |

3360x1290 x2100 |

3620x1050 x2200 |

3715x1520 x2450 |

4750x1550 x2460 |

67250x1550 x2500 |

Related Keywords