High Output PVC pipe extrusion line

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Jiangsu, China |

|---|---|

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

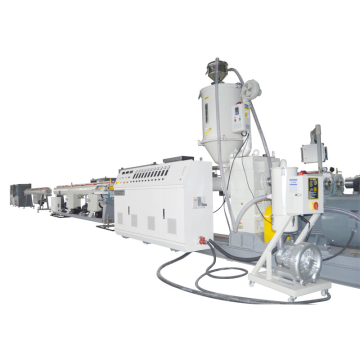

High Output PVC pipe extrusion line

PVC PIPE EXTRUSION LINE

For Four Strand pipe Extrusion line, LB-32 furnish a high efficiency with the Four Strand model. It delivers the line measurement with the scope of 16-63mm. For the creation line with multi-strand, one of the main highlight consideration is programmed grade. The Four Pipes ought to be created independently. That implies, assuming one strand pipe runs crazy, different strands ought not be impacted and expels as ordinary. The inside PLC framework helps machine working autonomously from pipe line.

SPECIFICATIONS

|

MODEL |

PIPE DIAMETER (MM) |

EXTRUDER MODEL |

MOTOR POWER (KW) |

|

LB-32F |

16-32 (FOUR PIPE) |

SJSZ65/132 |

37 AC |

|

LB-32E |

16-32 (DOUBLE PIPE) |

SJSZ51/105 |

22 AC |

|

LB-32W |

16-32 (DOUBLE PIPE) |

SJSZ65/132 |

37 AC |

|

LB-40E |

16-40 (DOUBLE PIPE) |

SJSZ51/105 |

22 AC |

|

LB-40W |

16-40 (DOUBLE PIPE) |

SJSZ65/132 |

37 AC |

|

LB-50E |

16-50 (DOUBLE PIPE) |

SJSZ51/105 |

22 AC |

|

LB-50W |

16-50 (DOUBLE PIPE) |

SJSZ65/132 |

37 AC |

|

LB-63W |

16-63 (DOUBLE PIPE) |

SJSZ65/132 |

37 AC |

FOUR OUTPUT = FOUR TIMES PRODUCTIVITY CAPACITY

For pipe with little measurement, man can pick Four Strand PVC pipe Production line. Simultaneously, four lines expulsion can build the efficiency, yet diminish the expense of machine, cost of human utilization and save the space of plant. For long time creation, man helps a ton from this sort of four strand pipe expulsion.

COMPONENTS INTRODUCTION

Conical twin screw extruder

PVC compounds are delicate to shearing and high temperatures. Thusly, we ought to tenderly handle on one or the other equal or conelike twin screw extruders, contingent upon the throughput prerequisites and line aspects. As the expert hardware, the Conical twin screw extruder can deal with not just PVC compounds, the combination of PVC and wood/composite yet in addition mixtures of PP/PE and wood powder.

Mould

The pvc pipe production is formed by shape with different unrefined components. The extraordinary planning of our form gives ideal thickness of material liquefying, which impacts the line molding and expulsion energy. All countenances in touch with material are cleaned, hence, the expulsion grinding can be limited.

Vaccum Calibration Tank and Cooling Tank

Through the Vacuum Calibration Tank, the line shape will be characterized. Other than that the surface nature of lines is impacted by this step. Our Vacuum Calibration Tanks are made with treated steel. The splashing spouts are intended for most extreme cooling execution. The Cooling water sprinkles on the hot plastic line surface. Joined with the forming of the shape, the surface nature of lines will be characterized.

The tension on our vacuum tank can be changed, so vacuum strain can be fixed by the line prerequisites. We seal gasket for each top on the vacuum tank. This stops vacuum spillage and limits energy utilization. We embraced the modern cycle innovation to ensure the nature of our items.

Haul-off Unit

We have an extensive variety of drag away units which can give clients to the ideal arrangement with the width scope of 16 to 800 mm.

Caterpillar and Belt Haul-off units can be taken on as per the creation conditions.The dragging speed can be associated with the expulsion speed, so the wall thickness are more even.

The Belt Haul-off unit is normally utilized for little line and fast expulsion. It is liberated from vibration and guarantee the superb control even at high velocity.The Caterpillar can take the huge lines without any problem. The Claws' surface is covering with froth PU which can forestall the slip among lines and paws.The speed setting of belts and caterpillar can be changed by inverter. In this way, man can work on the control board without any problem.

Cutter

A shaper with superior execution can guarantee similar length of the cut lines. So the top notch encoder and exact shaper unit are required. Comparative like Haul off unit, the shaper has two plan ideas: saw shaper and planet saw shaper. It relies upon the width of cutting lines.

Control system

The Control framework incorporates the entire activities related regulator and agent, for example, PLC module, HMI board (Human Machine Interface), thermometer, connector, etc. The Elements with excellent is critical for a steady and exact creation.

Discretionary unit

For pipe creation, there are a few utilitarian units like laser, ink printer, pipe stacker and attachment shaping machine.

With Printer the Pipe Manufacturer can compose the creation data on the Pipes.

Stacker can be utilized to gather the lines subsequent to cutting.

Attachment shaping machine can frame one finish of the line into a greater breadth, so the two lines can interface start to finish.

Cutting Unit Vacuum tank

Haul-off machine Control system of haul-off machine

Related Keywords