16-315mm PVC tube extrusion line

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | JIANGSU, CHINA |

|---|---|

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CIF,EXW,CFR |

| Certificate: | CE&ISO |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

16-315mm PVC tube extrusion line

PRODUCTION DESCRIPTION

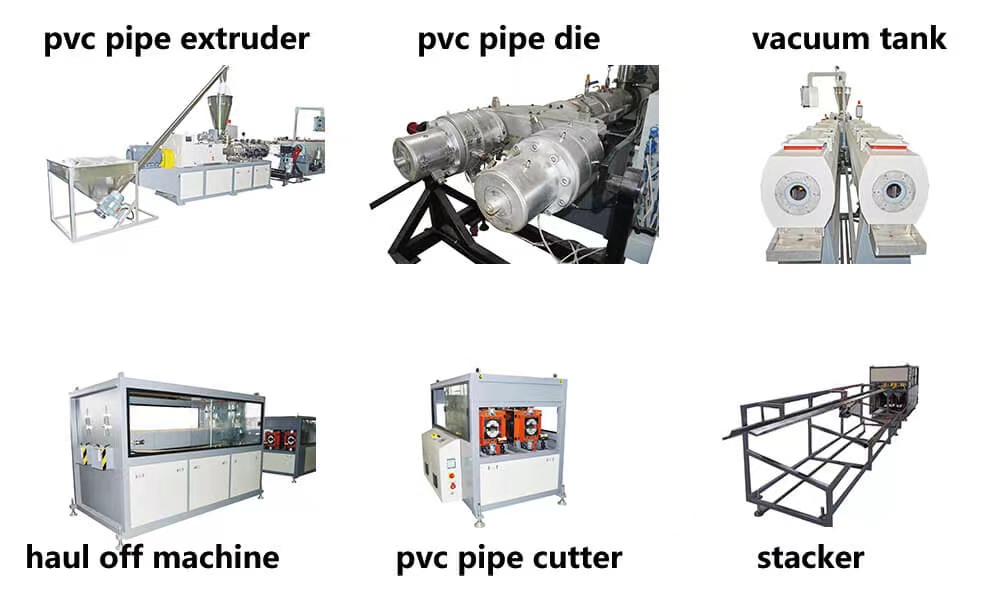

PVC Pipe Production Line consists of high speed mixing group, conical twin screw extruder, moulds, Vacuum diameter calibrating cooling water tank, haul-off, ink printer, saw cutter, stacker, ect.

The line applies unique screw design, which features with short remaining time for materials in the barrel, and good compounding and plasticizing effect. It adopts reduction box of super quality, with nice outline, stable running and low noise. Finned ceramic heater for barrel heating and air cooling system bring precise temperature controlling. Vacuum degassing system can get rid of moisture and volatile gas from the materials and guarantee the super quality of products. Main motor applies silicon controlled DC speed regulator or variable frequency speed regulator, which provides stable torque output and step less speed regulation. It is suitable for the processing of PVC or UPVC powder.

PRODUCTION FLOW:

Raw material + additive → Mixing → material conveying → Forced feeding → Conical twin screw extruder → extruding mould → Diameter control unit → Spraying vacuum shaping box → spraying/immersion type cooling water tank → marking machine → caterpillar tractor → cutter → pipe expanding machine → Pipe stacker → pipe inspection & packing

TECHNICAL PARAMETER:

|

Model |

Pipe diameter |

Extruder |

Extruder power |

Capacity |

|

LB-32A |

16-32(four) |

SJ65/132 |

37AC |

250 |

|

LB-32B |

16-32(four) |

SJ80/156 |

55AC |

350 |

|

LB-50A |

16-50 |

SJ45/90 |

15AC |

100 |

|

LB-50B |

16-50(double) |

SJ51/105 |

18.5AC |

150 |

|

LB-50C |

16-50(double) |

SJ65/132 |

37AC |

250 |

|

LB-63A |

16-63 |

SJ51/105 |

18.5AC |

150 |

|

LB-63B |

16-63(double) |

SJ65/132 |

37AC |

250 |

|

LB-160 |

50-160 |

SJ65/132 |

37AC |

250 |

|

LB-250 |

63-250 |

SJ65/132 |

37AC |

250 |

|

LB-315 |

110-315 |

SJ80/156 |

55AC |

350 |

|

LB-630 |

315-630 |

SJ92/188 |

110DC |

800 |

|

LB-800 |

560-800 |

SJ105/216 |

160DC |

1100 |

MAIN COMPONENTS OF PRODUCTION LINE

Conical twin-screw extruder: It equipped with forced fixed-quantity material feeding system, automatic temperature control system, vacuum exhaust system and automatic speed control system.

This structure assures accurate controlling for the material temperature, plasticization stability and greatly improving production speed. The main motor is direct convertor or frequency convertor.

PVC extruding molds: Material is high quality 40Cr. Molds surface is dealt with polishing and chrome plating. it adopts the structure of multiple head spiral. The melt has low pressure. Extruding at high quantity, the die head still maintain low temperature.

Vacuum calibrating water tank: The material of body is high hardness and good quality stainless steel board. It is high-pressure resistance, corrosion-resistance and two-stage for large diameter pipe.

Electricity controls water temperature.

The nozzle material is ABS engineering plastic. The frame of the machine can be adjusted three dimensions. The moving from front to back adopt cycloid reducer drive and up & down and left & right adopt screw adjustment.

Water spray cooling tank: The body is made of stainless steel and the shade is transparent soft PVC curtain. Stainless steel float adjusts water level and electricity controls water temperature. The nozzle material is ABS engineering plastic.

Haul-off machine: It adopts frequency conversion approach. Every traction frame transfers with chain which ensures every track moving simultaneously. It is pneumatic flexibility clamping.

Cutting machine: It is planetary cutting for large diameter. The blade takes rotation and cutting part and inserting blade part take revolution. It has angle cutting structure, pneumatic aluminum half clamping and cleaning device.

Control system: We can offer Siemens PLC controlling system which is intelligent controlling system. Also we can offer ordinary controlling system which use Siemens electrical parts, Omron temperature controller. Operation is simple.

Extruder Vacuum tank

Haul-off machine Vacuum tank with cooling function

Cutting machine Haul-off machine

Related Keywords