Environment Friendly pvc foam board extrusion line

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Jiangsu, China |

|---|---|

| Payment Type: | L/C,T/T,D/P,Paypal,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

Highly efficient pvc foam board extrusion line

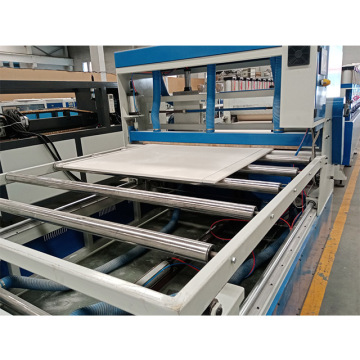

WPC/PVC FOAM BOARD EXTRUSION LINE

PVC/WPC Foam Board Production Line is also called PVC foam board extrusion line, foam board making machine. This extrusion line is designed for making PVC or WPC foam board with size 1220mm to 2450mm wide, 5mm to 50mm thickness boards, which can replace the nature wooden board and plywood, used for furniture and construction etc.

Equipment Composition List of PVC Crust Foam Board Production Line

No.

Equipment Name

Quantity

01

Material mixing and feeding system

1 set

02

SJSZ80/156 twin screw extruder

1 unit

03

PVC Foam extrusion mould

1 set (5-25mm thickness )

04

Calibration cooling table

1 set

05

Cooling roller brackets

1 unit

06

8 Pairs – 16 roller traction machine

1 set

07

Cutter

1 set

08

Stacking Machine

1 unit

09

Electric Control System

1 unit

No.

Equipment Name

Quantity

01

Material mixing and feeding system

1 set

02

SJSZ80/156 twin screw extruder

1 unit

03

PVC Foam extrusion mould

1 set (5-25mm thickness )

04

Calibration cooling table

1 set

05

Cooling roller brackets

1 unit

06

8 Pairs – 16 roller traction machine

1 set

07

Cutter

1 set

08

Stacking Machine

1 unit

09

Electric Control System

1 unit

PVC/WPC FOAM BOARD EXTRUSION LINE CONFIGURATION

1. The conical screw extruder keep a high output for the extrusion

2. T-die make the processing evenly (thickness is adjustable)

3. Shaping mould keeps a good shape and high precision of the finished PVC foamed board

4. Cooling trial with two side blades cutting for the thinner sheet

5. Laminating device

6. Haul-off device with normal 8 rubber roller groups and two side saws cutting for thicker board

7. The auto saw cutter the dust collection device

8. Stacker

PVC/WPC FOAM BOARD EXTRUSION LINE ADVANTAGES OF PVC FOAM BOARD PRODUCTION LINE

1. Main motor frequency controller: Siemens or ABB

2. Temperature controller: OMRON or RKC

3. AC controller: Schneider or Siemens (As customer requirement)

4. Thermal overload relay: Schneider

5. Switch: DELIXI or Schneider

6. All electrical units on components from standard companies like OMRON/RKC/Siemens

Related Keywords