Customized PVC Foam Production Line

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Transportation: | Ocean,Land |

|---|---|

| Port: | Shanghai |

Customized PVC Foam Board Production Line

APPLICATION & TREND OF FOAM BOARD

As a Report writes the global polymer foam market size was $114.88 billion in 2019 and it is projected to reach $157.63 billion by 2027, exhibiting a CAGR of 7.73% in forecast period.

https://www.fortunebusinessinsights.com/industry-reports/polymer-foam-market-101698

The applications, where the Foam Products are mostly used are the Automotive, Building, Packaging and Furniture Branch. They take the three quarter of the total application volume of Plastic Foam Product.

ADVANTAGES OF FOAM PRODUCTS

There are several advantages that this material offers making it a favorable choice for so many industries and sectors.

Some of those include heat resistance, corrosion resistance, fire resistance, easy to mould and paint, and high strength and durability.

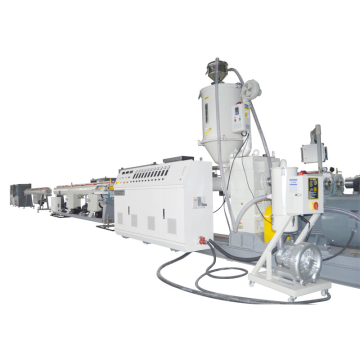

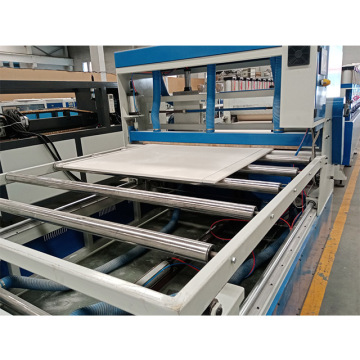

FOAM BOARD PRODUCTION LINE

LANGBO MACHINERY has continuously being optimizing its extrusion solutions during recent years. Our machine achieves a first class balance with high output and energy effectiveness.

For a long term stable running we chose the most suitable components. They have world wide quality and top energy efficiency can help to build up the professional foam board production line with high price-performance ratio.

For Foam Board Production Line the general processing step can be like this:

Mixing--Feeding---Extrusion----Forming and Cooling----Cooling---Hauling off -- Cutting

Take the Foam Board Extrusion Line with 450kg/h capacity for example the basic technical configuration could like this:

As a manufacture supplier, we are focusing to provide the most suitable production solution for our customer.

Pleases contact us to get customized production solution.

Related Keywords