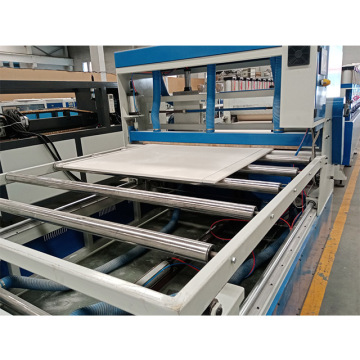

Double side skinning Foam Board Production line

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | JIANGSU, CHINA |

|---|---|

| Payment Type: | L/C,T/T,Western Union,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

PVC Foam Board Production Line

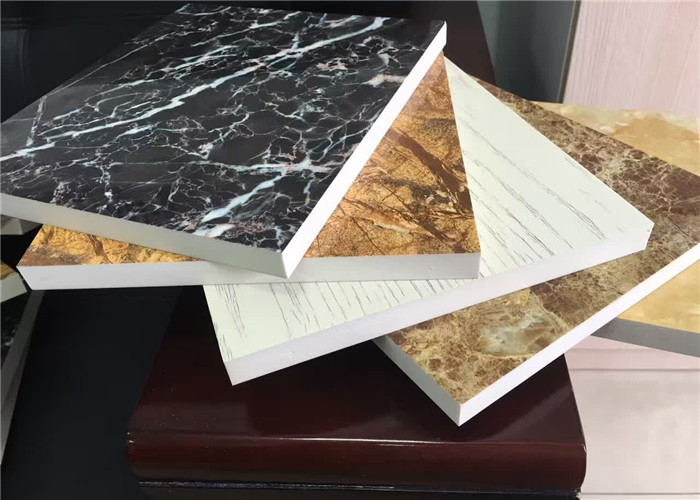

APPLICATION OF FOAM BOARD

A report shows the global polymer foam market size was $114.88 billion in 2019 and it is projected to reach $157.63 billion by 2027, exhibiting a CAGR of 7.73% in forecast period. The applications area of Foam Market and you can find, that the Automotive, Building, Packaging and Furniure Branch take the three quarter of the application of Plastic Foam Product.

(Link to report https://www.fortunebusinessinsights.com/industry-reports/polymer-foam-market-101698)

Transportation:such as steamship,aeroplane,carriage,train compartment, roof shed, case core layer, inner upholster,etc.

Architecture:such as building wall board,decoration board,housing, office, public building interlayer, commercial decoration shelf,non-dust room board,ceiling plate,etc.

Advertisement:such as screen printing, computer lettering,ad board,etc.

There are several advantages that this material offers making it a favorable choice for so many industries and sectors.

Some of those include heat resistance, corrosion resistance, fire resistance, easy to mould and paint, and high strength and durability.

PVC FOAM BOARD PRODUCTION LINE

LANGBO MACHINERY has continuously being optimizing its extrusion solutions during recent years. Our machine achieves a first class balance with high output and energy effectiveness.

For Foam Board Production Line the general processing step can be like this:

Mixing--Feeding---Extrusion----Forming and Cooling----Cooling---Hauling off -- Cutting

Take the Foam Board Extrusion Line with 450kg/h capacity for example the basic technical configuration could like this:

As a manufacture supplier, we are focusing to provide the most suitable production solution for our customer.

Pleases contact us to get customized production solution.

TECHNOLOGY AND SERVICE

-

A professional team provides a comprehensive service for the complete process for our customers. For example production layout, technical configuration, product delivery, handover, Operation and Maintenance Training, wearing part maintenance and machine repairs.

-

With the strong technical competence and experience, we are ready for every kind of innovations for the most suitable customized production solutions and timely after-sales service

SERVICE:

-

We provide a basic formula to our customers for each project. And our engineers will help customers to do formula adjustments according to requirements.

-

Our engineer will help customers to install the machines in the Customer’s factory.

-

We provide machine operation and maintenance training for our customers.

- With our professional after sales team we can response your production problem as soon as possible.

Related Keywords