Plastic Tube Ppr Pipe For Water System

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | JIANGSU, CHINA |

|---|---|

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CIF,EXW,CFR |

| Certificate: | CE |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

Plastic Tube Ppr Pipe For Water System

PPR PIPE CHARACTERISTICS

Since its development in the early 90’s the application of PP-R pipe has become commonplace. As a manufacturer, we explain you may some characters of PP-R Pipe.

Low Thermal Conductivity

The thermal conductivity of PPR is very low, meaning temperature cannot easily be conducted from the outside environment to the liquid in the pipe, and vice versa. This factor reduces heat loss or gain during the transferring of hot or cold fluids respectively, resulting in energy efficient systems and lower insulation costs for PPR piping.

Long Service Life & Durability

PPR piping systems can remain functional for over 50 years, at a wide range of fluid and environmental operating temperatures. Moreover, PPR pipe exhibits excellent durability in both hot and cold water systems. Firstly, it can endure the temperature and pressure strain of hot water systems.

At the same time PPR pipe is able to structurally withstand impacts even in cold weather installations without any risk of cracking or breaking, unlike other common types of plastic piping.

Efficient Inner Surface

The inner surface of PP-R pipe is very smooth and boasts a very low friction coefficient, compared to traditional types of piping. This results in a reduction of pressure losses during fluid transport and distribution, further contributing to the energy efficiency of PPR piping systems. Moreover, unlike metal pipes PPR does not flake or scale, making them safer to use.

Chemical & Mechanical Endurance

Compared to traditional plastic piping systems, PP-R offers very high resistance against abrasion by hard particles. This is especially important in cases of well water or industrial applications, where the transferred liquids may contain abrasive particles.

Moreover, unlike traditional metal piping, PPR is inert to most electrolytes and chemicals, over a wide range of temperatures. This electrolytic and chemical inertness makes PPR piping safe to use in cases of high water salinity (e.g. in pool applications that use sea water) or even highly corrosive chemicals (e.g. in industrial applications).

Ecological & Economic Efficiency

Due to the low weight of PPR pipe, their transport, handling, and installation doesn’t require high amounts of energy consumption or manual labor. At the same time they are very easy to cut, join, and work with, making them even more economically sustainable.

Moreover, joining PP-R pipe and fittings is performed solely through heat and doesn’t require any additional chemicals or materials. All of these factors contribute to PPRs low environmental impact and usage cost.

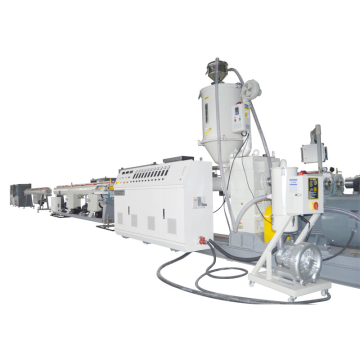

CUSTOM PLASTIC PIPE EXTRUSION SOLUTIONS

With over 20 years of industry experience, LANGBO MACHINERY is an international company in providing plastic pipe extrusion solution and profile extrusion solution. From plastic extruder to turnkey plastic extrusion solution, we supply high quality machinery and downstream equipment comprised only of top brand components.

Related Keywords