PPR-Pipe Production Line For Hot or Cold Water

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | JIANGSU, CHINA |

|---|---|

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CIF,EXW,CFR |

| Certificate: | CE |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

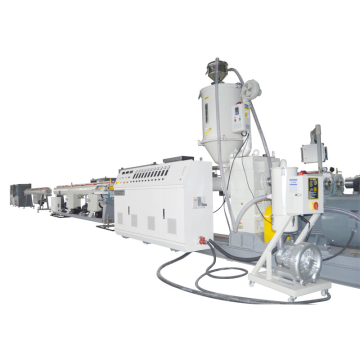

PPR-Pipe Production Line For Hot or Cold water

SINGLE SCREW EXTRUDER FOR PIPE MAKING

The single screw pipe extrusion machine is multi-functional: the extruder can be used to produce HDPE Silica core tube, common PP-R, PE, PEX PIPE, etc.

* With special milling single screw extruder, we adopt high-speed screw to reach a high-efficient output;

* Die mould of special design and reasonable sprue ensure the lubricity of pipe inner wall;

* Pipe Production Range:φ20-φ160mm, Production speed: 16m/min.

* Low cost: Nanometer anti-sepsis pipe only 5-10% higher than a normal model of pipe.

SHORT DESCRIPTION FOR PRODUCTION LINE:

* SJ series high efficient single screw PE pipe extruder is developed by our company adopting German latest advanced technology. Screw is optimization that composing separate type screw with mixing parts. Barrel is optimization that composing groove barrel with lengthened feeding segment. There are advantages as following by combining separate type screw with groove barrel:

* It's optimized in the whole material melting process. By this way, we can get more extrusion throughput. It is achieved that the extruding material melt in a much lower temperature.

* Cutting function is produced through separate clearance and makes raw material equally. It is controlled in the melt plasticization process. Therefore, the granules that have a smaller separate clearance can enter the melting channel.

* It has a wide manufacturing range for different materials. It is suitable for all kinds of polyolefin materials and especial for materials as HDPE, PP and PPR pipes.

PPR EXTRUSION LINE SPECIFICATIONS:

|

Model |

Pipe diameter |

Extruder |

Extruder power |

Capacity |

|

LB-63 |

16-63 |

SJ65/33 |

55AC |

150 |

|

LB-110 |

20-110(double) |

SJ75/33 |

75AC |

280 |

Model

Pipe diameter

Extruder

Extruder power

Capacity

SJ25/25

25

25:1

25-130

1-3

SJ30/25

30

25:1

25-150

2-8

SJ45/30/33

45

30:1,33:1

8-100

4-50

SJ65/30/33

65

30:1,33:1

12-150

50-120/50-250

SJ75/33

75

33:1

12-120

50-350

SJ90/30/33

90

33:1

10-120

100-320/100-550

SJ120/30/33

120

33:1

9-90

200-500/200-800

SJ150/30/33

150

33:1

7-75

300-800/500-1200

Related Keywords