PP-R Three Layer 20mm-63mm Pipe Production Line

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | JIANGSU, CHINA |

|---|---|

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CIF,EXW,CFR |

| Certificate: | CE |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

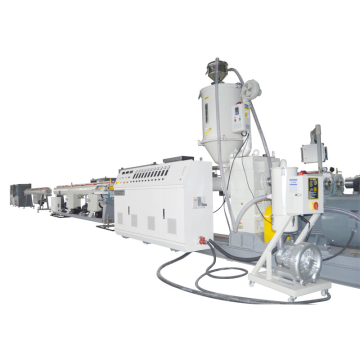

PPR Three Layer 20mm-63mm Pipe Production Line

CHARACTER & APPLICATIONS OF PP PIPES

The Raw material, Polypropylene (PP) is a kind of partly crystalline thermoplastics which is similar to HD-PE. Compared with HD-PE, it has the features of higher stiffness, strength, and hardness levels. One of the significant character of PP is its excellent chemical resistance. The PP Pipes can be used for chemical industry. It can handle with the aggressive waste water, even the water are used at high temperature. Because Polypropylene can be used in temperatures up to 95 °C. However, below the freezing point, PP is very sensitive and vulnerable.

INTRODUCTION OF COMPONENTS

-

Single screw Extruder

Screw and barrel are produced by professional factory with good quality. With Siemens Motor and ABB frequency inverter the Driving unit guarantees a long term stable running. Heating method is chosen by Electric aluminum cast heating element.

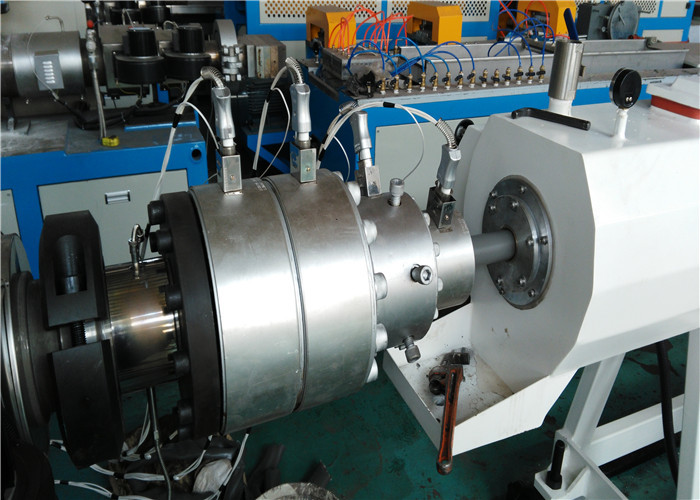

- Mould

The Mould shapes the melting material to pipe form. The designing of our mould provides ideal viscosity of material melting, which influences the pipe shaping and extrusion energy. All faces in contact with material are polished, so that the extrusion frication can be minimized.

-

Vaccum Calibration Tank & Cooling Tank

Through the Vacuum Calibration Tank, the pipe shape will be defined. Besides that the surface quality of pipes is influenced by this step. The Cooling water sprinkles on the hot plastic pipe surface. Combined with the shaping of the mould the surface quality of pipes will be defined.

Our vacuum tank’s pressure can be adjusted, so vacuum pressure can be fixed according to pipe requirement. We sealing gasket for every lid on the vacuum tank. This stops vacuum leakage and minimizing energy consumption.

- Haul off Unit

A wide range of haul-off units allows us to supply to the customers the ideal solution for a large diameter range.

Caterpillar and Belt Haul-off units can be adopted according to the production condition.

Haul-off speed can be connected with the extrusion speed, so that the wall thickness are more symmetrical.

The Belt Haul-off unit is usually used for small pipe and high speed extrusion. It is free from vibration and ensure the excellent control even at high speed.

The Caterpillar can take the big pipe easily. The Claws' surface is covering with foam PU. This can prevent the slip between pipes and claws.

The speed setting of belts and caterpillar can be

adjusted by inverter and man operates on the control panel easily.

- Cutter

A cutter with high performance can ensure the same length of the cut Pipes. So the high quality encoder and precise cutter unit are needed. Similar like Haul off unit, the cutter has two design concept: saw cutter and planet saw cutter. It depends on the diameter of to cut pipe.

- Control system

The Control system includes the whole operations related controller and executor such as PLC module, HMI panel (Human Machine Interface), thermometer, connector and so on. The Elements with high quality is significant for a stable and precise production.

- optional unit

For Pipe Production, there are some functional unit like laser/ ink printer and pipe stacker

With Printer the production information will be printed on the Pipes.

Stacker collects the pipes after cutting.

SPECIFICATIONS

Production Capacity has a close relationship with screw size and motor power.

For customized solution and details please feel free to contact us.

Related Keywords