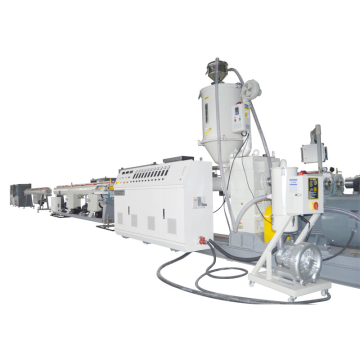

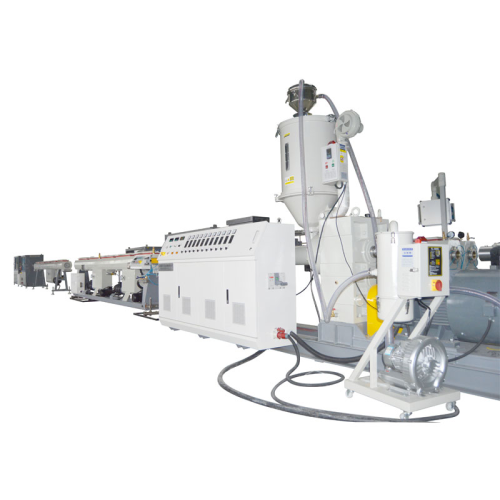

PP-R Multi Layer Pipe Production Line

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | JIANGSU, CHINA |

|---|---|

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CIF,EXW,CFR |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

PP-R Multi Layer Pipe Production Line

FEATURES AND APPLICATIONS OF PP-R MULTI-LAYER PIPES

The PP-R Pipe is very thermally stable, perfectly compatible, and can be easily integrated into all standard welding procedures.

For the application of Water Supply Pipe, the PP-R Pipe fulfills the following three significant characteristics.

· Pipe must be resistant to internal pressure and highly heat-resistant.

· Pipes in heating systems must be gas-tight.

· Pipes must prevent metal components corrosion in heating system through oxygen penetration and diffusion.

FEATURES OF MULTI-LAYER PP-R PIPE CO-EXTRUSION LINE

- Independently developed high efficiency PPR Extruder and Glass-fiber Extruder are applied, especially in the Glass-fiber Extruder that is specially designed according to glass-fiber feature, with advantages of high wear resistance and corrosion resistance, effectively ensuring the stable extrusion.

- The adjustable co-extrusion die head, our patent product, can composite multi-layer evenly and rapidly and get optimal thickness of each layer quickly without adjusting the extruder rotating speed. Thus, the design can reduce the dependence on operator’s skill during the production process.

- The combined cutting system can guarantee the rapid and dustless cutting of different diameters’ pipes during the high speed production. The control technology, which is self-developed according to pipe cutting characters, ensures higher accuracy of cutting during the high speed production and eliminates the problems of printing being not synchronous with cutting, uneven pipes’ length, etc.

- It can be upgrade by machine configuration renovation to produce high speed three layers or single layer HDPE pipe.

ADVANTAGES OF PP-R PIPES

PPR Pipes take over the features of plastic material and overcome several disadvantages of conventional material of Pipe like metal.

- Safety of potable water and long-term reliability

- Resistance to corrosion, tuberculation, deposits

- Chlorine and chloramine resistance

- Lightweight, easy to transport

- No scrap value, avoiding jobsite theft

- Durability and toughness to survive jobsite installations

- No flame, glue or solders are used for joining, heat-fused joints

- Available in wide range of sizes

- Natural Insulator, low thermal conductivity

- Professional installed appearance

SPECIFICATION

Production

Capacity has a close relationship with screw size and motor power. The

following table provide you a roughly classification of our pipe

production solution.

For customized solution and details please feel free to contact us.

LB-65

LB-60

Line Model

Screw Diameter

L/D

Production Scope

Extruder Output

Nominal Power

L×w×h

ф65/50mm

33:1

ф20-63mm

150kgs/h

91KW

24×2.5×3

ф60/65mm

36/33:1

ф20-110mm

340kgs/h

157KW

36×2.5×3

LB-75

Ф75/60mm

36:1

ф20-110mm

550kgs/h

248KW

45×2.5×

Related Keywords