PPR-Water Supply Pipe Prodcution Line

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | JIANGSU, CHINA |

|---|---|

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CIF,EXW,CFR |

| Certificate: | CE |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

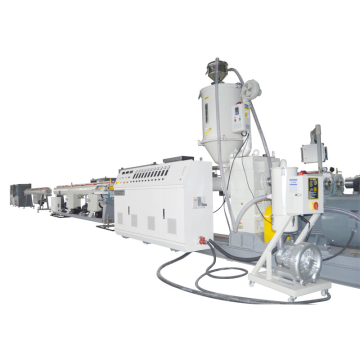

PPR-Water Supply Pipe Production Line

ADVANTAGES OF PP-R PIPES

PPR Pipes take over the features of plastic material and overcome several disadvantages of conventional material of Pipe like metal.

- Safety of potable water and long-term reliability

- Resistance to corrosion, tuberculation, deposits

- Chlorine and chloramine resistance

- Lightweight, easy to transport

- No scrap value, avoiding jobsite theft

- Durability and toughness to survive jobsite installations

- No flame, glue or solders are used for joining, heat-fused joints

- Available in wide range of sizes

- Natural Insulator, low thermal conductivity

- Professional installed appearance

PP-R PIPE PRODUCTION LINE PRESENTED BY LANGBO MACHINERY

With the large demand of plastic pipes and increasingly energy and raw material costs, LANGBO MACHINERY has continuously being optimizing its pipe extrusion solutions recent years. Our PE Pipe Production Line achieves a first class balance with high output and energy effectiveness. Meanwhile, our machinery components are brand with a high performance. Our machine concept is based on economical high performance extrusion. And the certifications prove our commitment to optimal processes and responsibility for our environment. We have sophisticated process technology and considerate services which will make customers feel thoughtful and reassuring.

For a customized production solution please contact us to get more detail information.

COMPONENTS INTRODUCTION OF THE PRODUCTION LINE

Single

Screw Extruder(with vacuum loader)

Screw and barrel are chinese famous brand, with good quality. Siemens Motor; Heating method Electric aluminum cast heating; Electric contactor Siemens; Frequency inverter ABB with high quality

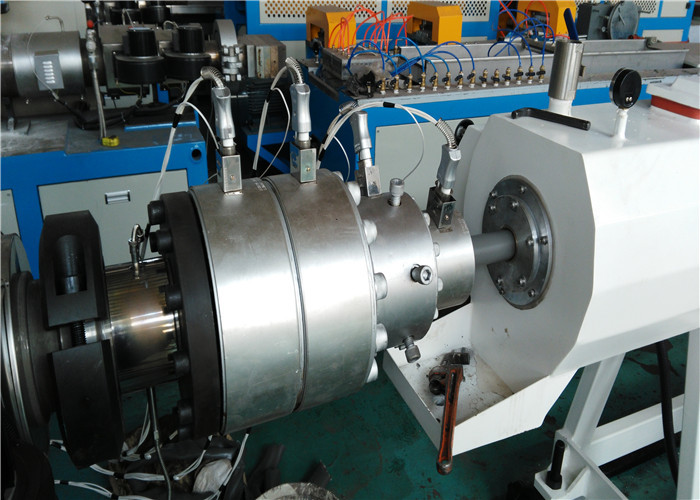

Mold Head

Standard Pipe diameter:20mm-160mm

Sizing unit:20mm,25mm,32mm,40mm,50mm,63mm,75mm,90mm,110mm,125mm,160mm

Size unit material: Copper alloy steel

Vacuum Calibration and Cooling Tank

Tank effective length:6 meters

Tank Raw material:#304 stainless steel

with Vacuum pump and Water Pump

Water Cooling Tank

Tank effective length:6 meters

Tank Raw material:#304 stainless steel

With water pump

Haul off Machine

Effective traction length:1.8meter

Motor power:4KW

Traction speed:2-6m/min

Speed control: by ABB inverter

Cutting Machine

Cutting method: Non-dust cutting

Cutting knife raw material: alloy steel

Cutting range:20mm-160mm

SPECIFICATIONS

Production Capacity has a close relationship with screw size and motor power. The following table provide you a roughly classification of our pipe production solution.

For customized solution and details please feel free to contact us.

|

MODEL |

Pipe diameter(mm) |

Extruder |

Extruder power(kw) |

Capacity(kg/hr) |

|

LB-63 |

20-63 |

SJ65/33 |

55AC |

150 |

|

LB-110 |

20-110 |

SJ65/33 |

55AC |

150 |

|

LB-160 |

75-160 |

SJ75/33 |

90AC |

280 |

|

LB-250 |

90-250 |

SJ75/33 |

110DC |

350 |

|

LB-315 |

110-315 |

SJ90/33 |

160DC |

450 |

|

LB-450 |

160-450 |

SJ90/33 |

160DC |

450 |

|

LB-630 |

315-630 |

SJ120/33 |

280DC |

850 |

|

LB-800 |

500-800 |

SJ150/33 |

315DC |

1100 |

|

LB-1200 |

710-1200 |

SJ150/34 |

400DC |

1350 |

Related Keywords