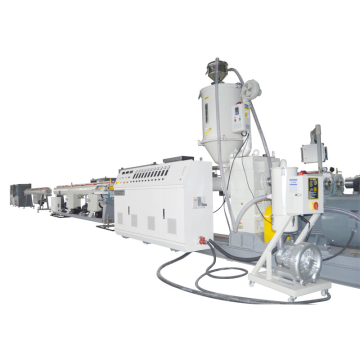

Vacuum Cleaner PE Pipe production line

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | JIANGSU, CHINA |

|---|---|

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE/ISO |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

Vacuum Cleaner PE Pipe production line

APPLICATIONS OF PE PIPE

PE polyethylene pipe is divided into many types, which can be divided into water supply pipe, gas pipe, mining pipe, sewage pipe, and non-excavation cross pipe threading pipe. According to raw materials can be divided into HDPE, LDPE, LLDPE. The PE pipe is a replacement product of traditional steel pipe and PVC drinking water pipe. The pipe has a smooth inner wall, low frictional resistance, good low-temperature resistance, corrosion resistance, safety and health, good flexibility and other excellent features; in addition, the product is light in weight, easy to install, handle, connect, convenient and reliable construction, long service life more than 50 years.

The unique hot-melt butt joint and hot-melt bearing connection technology make the joint strength high and connect with the pipe body to ensure the safety and reliability of the interface.

FEATURES OF PIPE PRODUCTION LINE

1. Automatic feeding and drying.

2. The extruder adopts highly efficient length diameter ratio screw structure with high production efficiency.

3. Two stage vacuum calibration tank, and the water spraying tank is made of 304 stainless steel.

4. The haul-off machine adopts crawler type, with large tractor and variable frequency speed regulation.

5.The cutting machine adopts annular dust-free cutting, and the pipe wall is smooth.

6.The stacker adopts the proximity switch to control the fixed length, and the cylinder controls the blanking after cutting.

The extruder adopts Siemens Motor, ABB inverters, Omron temperature controllers, Schneider breakers high quality components.

AFTER-SALE SERVICE & TECHNOLOGY SUPPORT:

· To install products and test products freely for customers.

· To provide the formulas and technologies of relevant products and the information of chemical

· materials manufacture

· To direct technology aspect of relevant use according to customers’ requirements

· To provide technical training for clients’ employees.

· To be responsible for maintenance service, door-to-door service under the necessary

Related Keywords