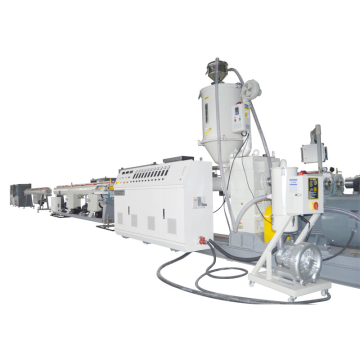

PE/PP Pipes Production line for different pressure classes

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | JIANGSU, CHINA |

|---|---|

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CIF,EXW,CFR |

| Certificate: | CE |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

PE/PP Pipes Production line for different pressure classes

APPLICATIONS OF PE PIPES

According to the different pressure classes of working conditions, the PE Pipes can be applied in field of petrol gas, agriculture, architecture, telecom communication etc..

The PE Pipes with small diameter are widely used in the telecom communication field.

ADVANTAGES OF PE PIPES

PE Pipes take over the features of plastic material and overcome several disadvantages of conventional material of Pipe like metal.

-

Corrosion Resistant

-

With self-extinguishing and flame retardant;

-

Excellent in anti-aging character

-

The weight of PVC pipe is light, easy to flaring, bonding, bending, welding.

-

Installation workload and Processing cost are lower than metal pipe

-

Good electrical properties of resistance

-

Recycled and Environment-friendly.

COMPONENTS INTRODUCTION

Single screw Extruder

Screw and Barrel produced by professional manufacture

Siemens Motor for extrusion for reliable continuous production

Cast aluminum heater for long lifetime

Siemens electrical contractor in control cabinet

ABB Frequency inverter for speed control

Extrusion Die

Optimized design for smooth molten polymer flowing

Precision processing and surface quality

Low extrusion energy consumption

Vacuum Calibration Tank & Cooling Tank

Intelligent control of water temperature

Automatic water cycling system

Adjustable vacuum condition

Copper calibrator for exact pipe diameter

Optimized layout of spraying nozzles

Stainless steel tank body

Energy efficiency vacuum effect in calibration tank

Haul off Unit

Caterpillar and Belt pullert for different application

Synchronized control between extruder and haul off available.

Pipe Wall thickness monitor optional

Haul-off speed controlled by Frequency inverter

Haul-off unit can be easily operated on main control panel

Cutter Unit

Precises cutting length

Different cutting concept for applications

Control system

Worldwide quality for electrical components

HMI panel optional

Optimized program and HMI Layout

Optional Device

Laser/Ink Printer

Automatic Stacker

Dosing unit

Pipe Wall Thickness monitor

SPECIFICATIONS

Production Capacity has a close relationship with screw size and motor power. The following table provide you a roughly classification of our pipe production solution.

For customized solution and details please feel free to contact us.

|

MODEL |

Pipe diameter(mm) |

Extruder |

Extruder power(kw) |

Capacity(kg/hr) |

|

LB-63 |

20-63 |

SJ65/33 |

55AC |

150 |

|

LB-110 |

20-110 |

SJ65/33 |

55AC |

150 |

|

LB-160 |

75-160 |

SJ75/33 |

90AC |

280 |

|

LB-250 |

90-250 |

SJ75/33 |

110DC |

350 |

|

LB-315 |

110-315 |

SJ90/33 |

160DC |

450 |

|

LB-450 |

160-450 |

SJ90/33 |

160DC |

450 |

|

LB-630 |

315-630 |

SJ120/33 |

280DC |

850 |

|

LB-800 |

500-800 |

SJ150/33 |

315DC |

1100 |

|

LB-1200 |

710-1200 |

SJ150/34 |

400DC |

1350 |

Related Keywords