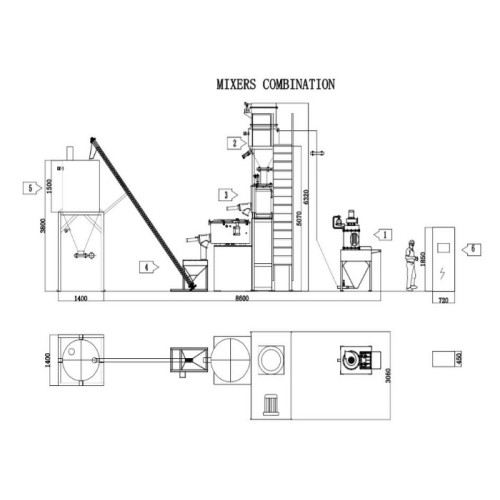

Plastic Material Mixer Combination 200/500

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | JIANGSU, CHINA |

|---|---|

| Productivity: | 200L/500L |

| Payment Type: | T/T,D/P,Western Union,L/C |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE/ISO |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

Plastic Material Mixer Combinations 200/500

MIXER FOR PLASTIC PROCESSING

In accordance with the various plastic materials and application requirements, the mixing work always need to be optimized in order to realize a perfect mixing result. In that case, a successful final product is always based on the optimum mixtures. Therefore, an excellent mixer combination with high performance plays an important role in the production line.

PVC is one of the examples for the application of mixer combination. Production processing requires that PVC and additives should be fully integrated in the heating and cooling mixer. For a shorter waiting time, hoppers before

are suggested. Meanwhile,According to the processing requirement, the mixed material could be used after storage.

EXCELLENT DESIGN AND QUALITY

The stable and reliable product depends on the excellent design and high manufacturing quality. With over twenty years experience, our engineers have their own unique opinions on the design and manufacturing way of the mixers. The pros of the heating concept is the usage of self-friction, which combines high energy efficiency with better heating effects. The cooling concept means water cooling, which is faster and more reliable.

The Mixer combination is made of stainless steel 304 and has mirror polishing treated.The barrel covers and three direct links are made by cast aluminum. The bearings are specially designed with the lubricating oil injection part. Driving motor has the latest protection design. PLC touch screen control system can be adopted for the requirements of high automatic control. Mixing axis are especially designed that can avoid the raw material leaking from the barrel. Those unique design ensure a much longer service time for the mixers. All the experience around the mixer, machine quality and experienced engineer are our core competence for the competition of the mixing market.

CUSTOMIZED SOLUTION

Composite Mixer is often applied in the plastics production line. WPC and PVC composites are most commonly used. Concerning different application and processing concepts, the mixing ways could also be various in order to guarantee the quality of final products. Based on our experience around mixing concept design and mixer manufacture, we are confident to providing you with the best mixing solutions and the whole extrusion concept.

Related Keywords