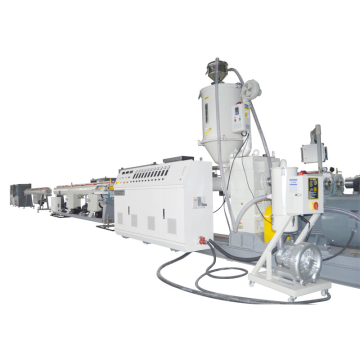

Plastic Mixer Machine For PVC Pipe Profile Making

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Jiangsu, China |

|---|---|

| Payment Type: | T/T,D/P,Western Union,L/C |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

Plastic Mixer Machine For PVC Pipe / Profile Making

Application:

Mixer is mainly used to mix and dry the mixture of phenolic resin, powders etc. It is one of the necessary equipment in the industrial of plastic & rubber, pharmaceutical, dyeing etc.

PVC plastics mixer makes the mixture more homogeneous. Meanwhile, it`s quite easy for operating and cleaning with its durable compact structure.

Stainless steel paddles with scientific structure, is able to mix raw material completely, minimizes load as well as saves time and electricity. It is made of premium stainless steel with high strength. And it is quite easy for operating and cleaning with its stable compact structure.

The unit possesses heat and cooling mixing craft. After heat mixing, the materials will be got into the cooling mixer for cooling automatically,exhausted remaining gases against agglomeration. The unit is developed by importing and advanced foreign technology. Therefore, the quality of those units is reliable and trustworthy.

Heating mixer has a series of functions as applying self-friction and heating by electricity. Cooler mixer absorbed slowdown technology from overseas. It adopts direct slowdown device and overcomes the deadly weakness caused by the usage of retarder. This machine has come up to the general level of the products in the worldwide industry. It is an ideal choice for producing plates, pipes and special-shaped materials etc.

USAGE AREAS OF MIXER:

- PVC Window & Door profiles

- PVC water pipes

- PVC cables

- PVC cable channels

- PVC Curtain Rails

- PVC Hoses

- PVC Water Isolation Membranes

- PVC Panels

- PVC Shoe Soles

- PVC Floor Covers

- PVC Shrink Film

- PVC Tent

Optional Accessories:

- The production will be with Soft starter, if frequency inverter is not ordered with the machine.

- The production will be with Microcontroller, if PLC is not ordered with the machine.

Mixture quantity:

· The density of mixture that are additives and raw material are calculated as 0.5kg/t and the temperature of mixture are up to 120 degrees centigrade. Depending on the auxiliary raw material, the loading system can be different.

· Changeable quantity will be impacted by temperature of the factory.

Machine features:

1.It starts from the high-speed mixing motor inverter.

2.There are three methods increasing the temperature in heating mixer: material self-friction, electric heating and conduction oil heating.

3.There are two ways for material discharge: temperature controller automatic release and mixing time control.

4.The connection parts which contact with raw materials are all made of stainless steel 304 and had mirror polishing treated.

5.The barrel covers and three direct links are made by cast aluminum.

6.The bearings are specially designed with the lubricating oil injection part.

7.Driving motor has the latest protection design.

8.PLC touch screen control system can be adopted for the requirements of high automatic control.

9.Mixing axis are especially designed that can avoid the raw material leaking from the barrel.

10.It can be used in all kinds of plastic mixing process.

11.The main shaft sealing device adopts the special materials with seal and oil resistant, high temperature resistant skeleton oil seal.

12.Heat mixer has the functions of self-friction, electrical heating and steam heating methods.

13.Pot with double sealing cold mix USES the arch instead of changeable forms.

14.It has a compact structure with beautiful and good-looking appearance etc.

15.It equipped with a dust filter unit.

16.The blades past through the Static balance test.

17.It obtains electrical manual and PLC automatic control.

Related Keywords