Plastic Recycling Line with Less 2% Moisture Content

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Jiangsu, China |

|---|---|

| Payment Type: | T/T,D/P,Western Union,L/C |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

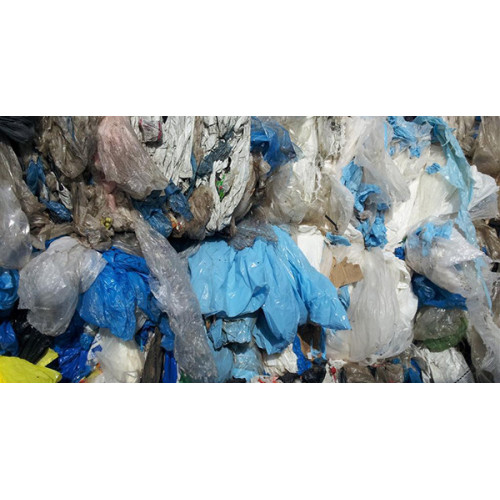

Plastic Recycling Line with Less 2% Final Moisture Content

Description:

HDPE bottle washing recycling line is specially designed for recycling HDPE milk bottles. HDPE milk bottle washing recycling line basic process: Belt conveyor- shredder- screw feeder- hot rinsing washing tank- high speed friction washer- rinsing washer- dewater- hopper. Capacity of HDPE milk bottle washing recycling line is 300kg/h, 500kg/h, 1000kg/h. We can produce HDPE milk bottle washing recycling line according to customer’s requirement.

Product advantages:

1. Crusher with friction washing dewatering device

Crusher working with water, it prewashes HDPE flakes. The flakes come to friction washing dewatering device, it remove stubborn stains and remove dirty water.

2. Paper label remover which is specially designed for removing paper labels on HDPE flakes.

First, it need soak HDPE flakes in hot-washing tank 20-30 mins. Then send HDPE flakes into paper label remover machine. Paper pulp and HDPE flakes discharge from different outlet.

3. High speed horizontal dewater machine, rotating speed reach 1800rpm, flnal moisture content is less 2%. Low power consumption, high efficiency.

Our Service

1. Pre-sale: we given

client the details technician offer, sign the sales contract etc.

2. In-sales: we supply the details layout, installation instruction, technician

support for the clients.

3. After sales: we arrange engineer to install the machinery and training the

workers for client.

4. We have 24 hours service team to solve the after sales problem.

5. We supply long term spare parts for every customer.

6. We always update the new technology to every customer.

Related Keywords