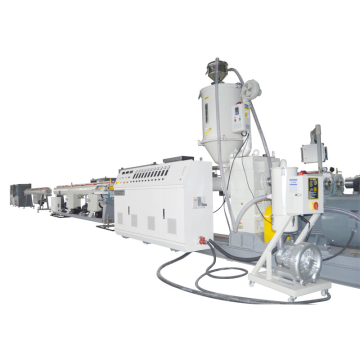

Conical Twin Screw Extruder For UPVC Pipe Making

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | JIANGSU, CHINA |

|---|---|

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE&ISO |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

Conical Twin Screw Extruder For UPVC Pipe Making

EXTRUDER FOR PVC PIPE EXTRUSION

As the plastic material, PVC is thermo- and shearsensetiv. With an optimized design and logic combination of core components our extrusion line has other benefits such as stable material feeding, gentle, non-destructive processing and highly stable screw pressure for the production. So that the homogeneous melt wit optimum temperature will be extruded.

EXTRUDER COMPONENTS INTRODUCTION

|

|

No. |

Name |

Brand |

|

1 Screw and barrel |

1 |

Design |

German design |

|

2 |

Main materials |

38CrMoALA |

|

|

3 |

Screw heating |

Silicon oil heating |

|

|

4 |

Barrel heater |

Cast aluminum heater |

|

|

5 |

Barrel has vacuum exhausting system |

||

|

|

|||

|

2 Driving parts |

1 |

Main motor |

Siemens Brand |

|

|

2 |

Gear box |

Top brand in China |

|

|

|||

|

3 Electric parts |

1 |

Inverter |

ABB brand |

|

2 |

Contactor |

Schneider brand |

|

|

3 |

Relay |

Schneider brand |

|

|

4 |

Breaker |

Delixi brand |

|

|

5 |

Temperature meter |

RKC brand |

|

|

6 |

Hauling motor |

Densen brand |

|

|

7 |

Hauling gear box |

Hard surface gear box |

|

|

8 |

Vacuum pump |

Yvhuang brand |

|

|

9 |

Water pump |

Yvhuang brand |

|

|

10 |

Cutting motor |

Siemens brand |

|

|

11 |

PLC |

Schneider brand |

|

|

|

|||

|

4 Mechanical parts |

We use CNC machines to ensure the precision of our mechanical parts |

||

|

|

|||

|

5 Protection system |

We have a whole set of protection system for our machines, such as: 1 Current overload protection 2 Torque overload protection 3 Oil path blocking alarm 4 Vacuum overload alarm, and so on. |

||

|

For more technical information please contact us by email. |

|||

PROCESS FLOW OF PVC PIPE EXTRUSION:

Raw material + additive → mixing → granulating → conical twin-screw extruder → profile extrusion mould → cool molding die → vacuum calibration support → belt haul-off → cutter → rack → finished product inspecting & packing

Related Keywords