Calibration of Reference Blocks For Checking JIg

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 200PCS /Week |

| Supply Ability: | 200PCS /Week |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF,EXW,CFR,DDU,DDP,Express Delivery |

| Certificate: | ISO9001 Quality Control System |

| HS Code: | 9031809090 |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Shanghai |

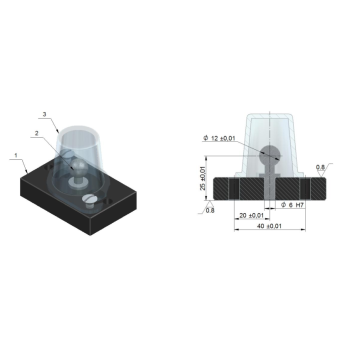

The gage reference block is used to establish the gage coordinate system, which is used for gage manufacturing and calibration, and the coordinate system established by the gage reference block is used to measure the parts during CMM detection. At least three φ 8H7 holes are used as the datum for measuring datum. Its actual coordinate value should be marked next to the datum block. The holes provide coordinates in two directions, and the surface of the datum block provides coordinates in the third direction. The design and assembly position of the reference block should be at the intersection of the hundreds line in two directions. If the base plate size or avoiding lifting lugs are affected, the design and assembly position of the reference block can be moved to the intersection of 50mm integer values in two directions of the hundreds line. Assembly with at least two positioning pins and two bolts.

Technical Parameter:

1. No chamfering C0.5, deburred

2. No tolernace of +/-0.3mm

Details Of Stainless Steel Bushing

Standard Sizes Part Number: 41-HD-JZT-B

Part Number: 41-HD-JZT-A

E-Catalogue Of Hongyi Tengda Automotive Checking Parts

Hot Selling Products

Our Factory and Quality Management

Currently We have 3 CNC high speed machining machines, 6 Punch Machines, 8 Grinding Machines, CMM Inspection, Projector, Digital Caliper etc. We have Production department, Quality Control department, Packaging Department, Sales and Design department, we have formed a standard work flow.

Related Keywords