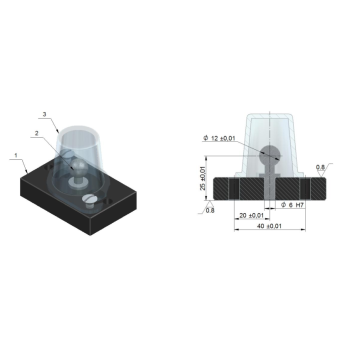

go and no go pin gauge

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Shanghai, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 300 pcs /Week |

| Supply Ability: | 100 PCS /Week |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF,EXW,CFR,DDU,DDP,Express Delivery |

| Certificate: | ISO9001 Quality Control System |

| HS Code: | 9031809090 |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Shanghai,Shenzhen |

FIXTURES

It is a work holding device that holds, supports and locates the workpiece for a specific operation but does not guide the cutting tool. It provides only a reference surface or a device. What makes a fixture unique is that each one is built to fit a particular part or shape. The main purpose of a fixture is to locate and in some cases hold a workpiece during either a machining operation or some other industrial process. A jig differs from a fixture in that a it guides the tool to its correct position in addition to locating and supporting the workpiece. Fixtures are made of tooling balls, clamping, checking pins and so on.

Plug Gauge For Automotive Checking Fixtures

Raw material: S136 HRC50-55 °+ Chrome Plated

Technical Request:

1. No chamfering C0.5, deburring.

2. No tolernace of +/-0.3mm.

3. The neutral salt spray test was performed for measuring part for 24 hours

And sizes can be customized.

Why choose us?

1.Our Inventory of Checking Components of automotive

We have thousands of checking fixtures components for automotive gauge in our warehouse, such as mechanism, measuring and adjustable holder, checking pins, plates and plastic cover, Go Nogo pins, inch tooling balls etc. We can provide fast delivery, improve efficiency, shorten production time, you could get it fastly as your local market under in the case of fierce competition of automobile fixture.

Standard Components Lead Time: 3-5 days.

Custom Components Lead Time: 7 Working day.

2.Our Design and 3D datas

3.Sample Service and Mass Production

MOQ: 1PCS, we can provide sample service to help you to test products' quality for first cooperation.

Relevant Jig Checking Components, such Checking Pins, Plastic Cover, Aluminum Alloy Cover, Spring, Metal Parts, Adjustable Holder etc.

4.Our Workshop and Quality Controll

Currently We have 3 CNC high speed machining machines, 6 Punch Machines, 8 Grinding Machines, CMM Inspection, Projector, Digital Caliper etc. We have Production department, Quality Control department, Packaging Department, Sales and Design department, we have formed a standard work flow.

Related Keywords